35

Chapter 6. Machine adjustment and setting up

GB

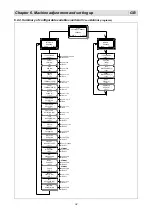

6.3. Alarms

The machine includes a series of ALARMS that are necessary in order monitor hazard and

fault conditions.

Whenever an alarm is activated, the display views the fault, together with an acoustic signal

and the red light element turns on (E2),

When the alarm is restored, the red light element and acoustic signal turn off.

ALARM

CAUSE

RESET

ALARM

STOP PRESSED

The emergency button has been pressed (S0).

Release the EMERGENCY button (S0)

by turning it to the right.

Press the RESET button (S1).

ALARM

DOOR OPEN

A door or the upper hood is open.

Close the door or the upper hood.

ALARM

IO [.…

]

Comunication lack between electronic card and

power boards (CAN-BUS).

Remove the alarm cause.

Press button

(16)

.

Press button

(13)

.

ALARM

MICRO ON BAR

Parcel remained under sealing bar.

One micro is out of its place or out of order.

Sensor on cylinder is out of its place or out of order.

Remove the alarm cause.

Press button

(16)

.

Press button

(13)

.

ALARM

THERMIC MOTOR

Not active.

Remove the alarm cause.

Press button

(16)

.

Press button

(13)

.

ALARM

INVERTER

Inverter block (check on the inverter display the

cause).

Remove the alarm cause.

Press button

(16)

.

Press button

(13)

.

ALARM

TOO FULL

Waste film winder roll, too full.

Remove the alarm cause.

Press button

(16)

.

Press button

(13)

.

ALARM

SEALING BAR RISE

The sealing bar doesn’t open.

Upper bar sensor is out of order.

Compressed air lack or solenoid valve is faulty.

Remove the alarm cause.

Press button

(16)

.

Press button

(13)

.

ALARM

BAR DESCENT

The sealing bar doesn’t open.

Upper bar sensor is out of order.

Compressed air lack or solenoid valve is faulty.

Remove the alarm cause.

Press button

(16)

.

Press button

(13)

.

ALARM

PHOTOCELLS

The photocells are darkened beyond the max.

configuration time, or not aligned or our of order.

Remove the alarm cause.

Press button

(16)

.

Press button

(13)

.

ALARM

BELT RETURN

Mobil conveyor is not drew back.

Compressed air lack.

Sensor our of order.

Remove the alarm cause.

Press button

(16)

.

Press button

(13)

.

ALARM

POSITION

Inconsistency between sensor signals.

Remove the alarm cause.

Press button

(16)

.

Press button

(13)

.

ALARM

SIDE RAMPE

Side sealing bar heating time fault.

Remove the alarm cause.

Press button

(16)

.

Press button

(13)

.

ALARM

FRONT RAMPE

Front sealing bar heating time fault.

Remove the alarm cause.

Press button

(16)

.

Press button

(13)

.

ALARM

SIDE ADJUST.

Side sealing bar does not remain at temperature

set.

Remove the alarm cause.

Press button

(16)

.

Press button

(13)

.

ALARM

FRONT ADJUST.

Front sealing bar does not remain at temperature

set.

Remove the alarm cause.

Press button

(16)

.

Press button

(13)

.

ALARM

SIDE PROBE

One sealing bars heater is not heating up.

Thermocouple out of place.

Remove the alarm cause.

Press button

(16)

.

Press button

(13)

.

ALARM

FRONT PROBE

One sealing bars heater is not heating up.

Thermocouple out of place.

Remove the alarm cause.

Press button

(16)

.

Press button

(13)

.

The machine is fitted with

“EMERGENCY” Pushbutton

(S0)

that stop the machine instantaneously when

pressed, interrupting the work cycle.

To reset this alarm, proceed as follows:

Remove the cause of the alarm. Release the “EMERGENCY” Pushbutton (S0) by rotating it to the right.

Press the RESET (S1) button

Summary of Contents for Pratika 56 CS Series

Page 108: ...107 7 4 ...

Page 109: ...108 7 4 ...

Page 110: ...109 7 4 ...

Page 111: ...110 7 4 ...

Page 112: ...111 7 4 ...

Page 113: ...112 7 5 ...

Page 114: ...113 ...