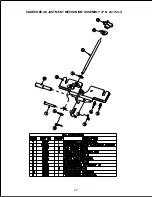

ITEM

PART NO.

REQ'D

DESCRIPTION

ITEM

PART NO.

REQ'D

DESCRIPTION

1

210066

2

DRIVE HUB RETAINER BLT

36

710180

2

SCR-MC 1/4-20 X .75 ZINC

2A

260002

2

PAD HLDR-26B

37

710129

2

SCR-MC 8-32 X .50 ZINC

2B

260003

2

BRUSH-FEED THRU BASSINE

38

710823

2

SC 1/4-20 X .50 NYL

2C

260004

2

BRUSH-26B NYL

39

710986

8

SC 3/8-16 X 1 ZINC

2D

260005

2

BRUSH-POLY GRIT 26B

40

711128

1

SCR-ST-B HI-LO 8 X .62 ZINC

2E

260006

2

BRUSH-STRATAGRIT 26B

41

711160

3

SCR-HI/LO #10 X 5/8 ZINC

3

260009

1

BATTERY TRAY 14GA

42

711203

2

BLT-HH 1/4-20 X .62

4

260030

8

BUSHING-.5015 X .628 X .375 OI

43

711210

2

BLT-HH 1/4-20 X 1.25 STL ZINC

5

260036

13

PIN, RETAINER

44

711228

2

BLT-HH 5/16-18 X .75 STL ZINC

6

260038PTD

1

MTR MOUNT WELDMENT RH

45

711334

2

NUT-HEX 1/2-13 ST PL

7

260039PTD

1

MTR MOUNT WELMENT LH

46

711368

2

NUT-WING NYLOC 1/4-20 PL

8

260041

13

BUSHING-FLG .502 X .750 X .375

47

711425

10

NUT-FLANGED WIZZ 1/4-20

9

260049

4

LINKAGE BAR .312GA

48

711505

3

WSR-FLT 1/4

10

260066

2

BUSHING-FLG .377 X .687 X .406

49

711510

2

WSR-FLT .50 X 1.37 X .10

11

260068

1

SPACER-SPRG

50

711517

2

WSR-FLT .77 X 1.37 X .03

12

51

711544

2

WSR-HELICAL 1/4

13

260077

1

MOTOR FRAME WELDMENT

52

711545

2

WSR-HELICAL 5/16

14

260137

1

SPRING-COMP .960 X 2.00 ZINC

53

711713

13

RET RING-E EXT .50

15

260150

1

BATTERY LINER

54

711808

2

PIN-HAIRPIN COTTER #13

16

260159

1

HOSE-VAC 1.5 X 78" WIRELOC

55

712301

6

WSR-FLT .37 X .87 X .06 (WIDE)

17

210466

1

CABLE CONDUIT

56

712310

25

WSR-FLT .52 X .87 X .06 PL

18

260183

2

NUT 1/4 NPT NYL

57

712667

1

NUT-HEX NYLOC 1/4-20 SS

19

260187

1

RETAINER BAR WELDMENT RH

58

740132

2

INSULATOR (GLASTIC)

20

260203

1

CLAMP-HOSE 102120 MURRAY

59

740159

1

CIRCUIT BRKR-175 RED HOUSING

21

260214

2

TNK CABLE ASY 260

60

740209

2

GEARMOTOR 24V 17B

22

260224

1

DRAIN HOSE 1/4 X 18 SILICONE

61

740225

1

VAC MTR 6515-13 24V

23

260250

1

RETAINER BAR WELDMENT LH

62

762073

1

BUSHING-.259 X .375 X .265

24

260315

1

LIFT CABLE BRACKET

63

809444

1

CLIP-CORD

25

260337

1

CABLE-SQUEEGEE

64

828264

1

WASHER CUP

26

290017

1

MOLDED VAC MOTOR GASKET

65

828490

1

CLAMP-CRIMP 140R

27

320248

2

PIN-CLEVIS, SLOTTED

66

829067

2

CLAMP-CRIMP 560R

28

320271

1

FITTING PP 90 3/8MPT 3/8HOSE

67

832996

1

TERMINAL BLOCK 2POLE VDE

29

320272

2

NOZZLE BODY LOCKNUT

68

833191

1

HOSE RUBBER FLEX 2X9

30

320273

1

CLAMP-HOSE SHUT-OFF

69

833265PLT

1

THREADED SPACER PLT ZINC

31

364-816

1

NUT-NYLOC 1/2-13 HALF

70

833325

2

FITTING NYLON 90 1/4MPT 3/8HOS

32

380064

1

RING, FOAM

71

833638

2

BRASS STUD

33

430035-1

2

DRIVE HUB W/ BRASS INSERT

72

840011

1

VAC MOTOR COVER TOP

34

450038-H

2

Z BKT 5.7 VDE ZINC

73

840012

1

VAC MOTOR COVER BOTTOM

35

450076

2

CLAMP-CRIMP 185R SS

PARTS LIST

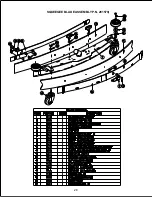

LINKAGE ASSEMBLY BOM (TRACTION DRIVE)

22

Summary of Contents for P260BDCE

Page 2: ......

Page 6: ...3 CONTROL PANEL IDENTIFICATION...

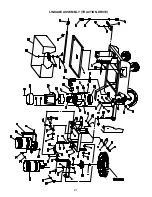

Page 10: ...EXPLODED VIEWS MAIN ASSEMBLY 7...

Page 12: ...SOLUTION AND RECOVERY TANK BRUSH DRIVE 9...

Page 14: ...MAINFRAME ASSEMBLY BRUSH DRIVE 11...

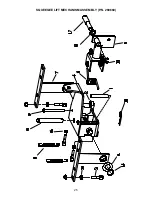

Page 16: ...LINKAGE ASSEMBLY BRUSH DRIVE 13...

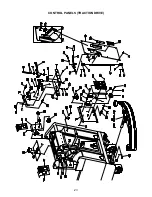

Page 18: ...CONTROL PANELS BRUSH DRIVE 15...

Page 20: ...SOLUTION AND RECOVERY TANK TRACTION DRIVE 17...

Page 22: ...MAINFRAME ASSEMBLY TRACTION DRIVE 19...

Page 24: ...LINKAGE ASSEMBLY TRACTION DRIVE 21...

Page 26: ...CONTROL PANELS TRACTION DRIVE 23...

Page 28: ...SQUEEGEE LIFT MECHANISM ASSEMBLY P N 260660 25...

Page 30: ...SQUEEGEE ADJUSTMENT MECHANISM ASSEMBLY P N 241730 1 27...

Page 31: ...SQUEEGEE BLADE ASSEMBLYP N 281579 28...

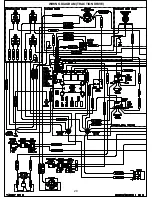

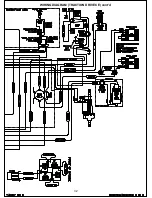

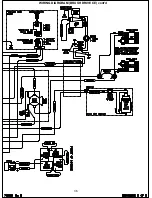

Page 32: ...WIRING DIAGRAM TRACTION DRIVE 29...

Page 33: ...WIRING DIAGRAM TRACTION DRIVE cont d 30...

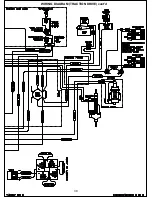

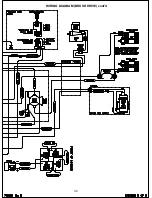

Page 34: ...WIRING DIAGRAM TRACTION DRIVE CE 31...

Page 35: ...WIRING DIAGRAM TRACTION DRIVE CE cont d 32...

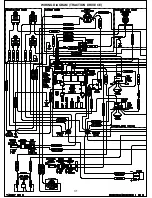

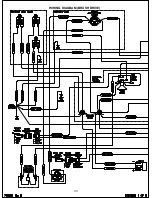

Page 36: ...WIRING DIAGRAM BRUSH DRIVE 33...

Page 37: ...WIRING DIAGRAM BRUSH DRIVE cont d 34...

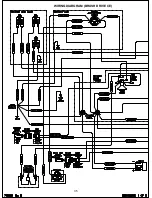

Page 38: ...WIRING DIARGRAM BRUSH DRIVE CE 35...