6

REAR SQUEEGEE ADJUSTMENT

1. Ensure that the scrubber is on a relatively flat surface. Turn on the key switch and lower the

squeegee to the floor using the squeegee lift lever. This turns the vacuum motor on.

2. Move the scrubber one or two feet forward slowly while someone behind the machine checks

the rear squeegee blade (item

A

) for uniform deflection to the floor.

3. If uneven deflection or lay is evident, minor adjustments may be necessary to avoid streaking

and uneven wear on the blade.

4. To correct this, loosen the wing jam nut (item

B

) in order to adjust the caster height. If the

squeegee blade is deflecting too much, the casters (item

D

) need to be lowered to control the

down pressure. Lower the caster by turning the exposed threaded stem (item

C

) on the

caster clockwise. Make the adjustment a few turns at a time.

Repeat step 2

.

5. If the blades are not deflecting enough, raise the caster by turning the stem counter-

clockwise to adjust the caster height to allow more down pressure on the squeegee.

Repeat

step 2.

6. Make sure there is even deflection on the entire length of the rear blade. Adjust the casters

and retighten the wing jam nuts to lock the caster setting in place.

7. Pitch adjustment is necessary if the outer ends on the squeegee blade do not contact the

floor and there is too much deflection in the middle area or if the outer ends are over

deflected and there is no contact in the middle.

8. To adjust the pitch, Repeat step 2.

9. Loosen the two wing jam nuts (item

E

) that lock the pitch angle. Turning the knob (item

F

)

clockwise or counter-clockwise controls the forward and backward pitch of the squeegee.

Having the rear blades deflected uniformly along its entire length is the desired set-up.

10. Repeat step 2 until desired set-up is achieved.

11. In certain applications where a non-slotted front wiper blade (item

G

) is needed, detach the

rear squeegee assembly by loosening the two wing bolts (item

H

). Unlock the toggle clamp

(item

I

) on the front squeegee to release the front long strap (item

J

) and slide the front short

strap (item

K

). Flip the blade over to the non-slotted side. Reattach the straps and lock the

clamp back in place.

12. You can also easily replace the rear blade by unlatching the latch (item

N

) and removing the

two rear straps (items

L

&

M

) by sliding them off the assembly. You can then flip the blade

over in order to use a new edge for better wiping action.

Summary of Contents for P260BDCE

Page 2: ......

Page 6: ...3 CONTROL PANEL IDENTIFICATION...

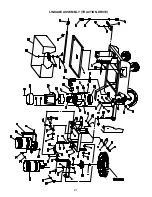

Page 10: ...EXPLODED VIEWS MAIN ASSEMBLY 7...

Page 12: ...SOLUTION AND RECOVERY TANK BRUSH DRIVE 9...

Page 14: ...MAINFRAME ASSEMBLY BRUSH DRIVE 11...

Page 16: ...LINKAGE ASSEMBLY BRUSH DRIVE 13...

Page 18: ...CONTROL PANELS BRUSH DRIVE 15...

Page 20: ...SOLUTION AND RECOVERY TANK TRACTION DRIVE 17...

Page 22: ...MAINFRAME ASSEMBLY TRACTION DRIVE 19...

Page 24: ...LINKAGE ASSEMBLY TRACTION DRIVE 21...

Page 26: ...CONTROL PANELS TRACTION DRIVE 23...

Page 28: ...SQUEEGEE LIFT MECHANISM ASSEMBLY P N 260660 25...

Page 30: ...SQUEEGEE ADJUSTMENT MECHANISM ASSEMBLY P N 241730 1 27...

Page 31: ...SQUEEGEE BLADE ASSEMBLYP N 281579 28...

Page 32: ...WIRING DIAGRAM TRACTION DRIVE 29...

Page 33: ...WIRING DIAGRAM TRACTION DRIVE cont d 30...

Page 34: ...WIRING DIAGRAM TRACTION DRIVE CE 31...

Page 35: ...WIRING DIAGRAM TRACTION DRIVE CE cont d 32...

Page 36: ...WIRING DIAGRAM BRUSH DRIVE 33...

Page 37: ...WIRING DIAGRAM BRUSH DRIVE cont d 34...

Page 38: ...WIRING DIARGRAM BRUSH DRIVE CE 35...