5

OPERATING INSTRUCTIONS

1. Filling: Fill the solution tank with the desired amount of water and add liquid cleaning solution to

the proper dilution ratio. DO NOT USE powdered cleaning chemicals. Powders are unlikely to

dissolve thoroughly, resulting in clogging the in-line solution filter. This can reduce or stop water

flow to the brush.

2. Lower brush assembly.

-

To lower the brush, first push the pedal slightly towards the center of the machine

(unlock it), then release it slowly.

-

To lift the brush, press the pedal down until lift mechanism engages.

3. Turn on brush switch.

4. Adjust solution control feed lever.

5. Turn on vacuum switch.

6. Lower squeegee assembly.

After Use:

1. Turn off solution feed.

2. Switch off brush and raise.

3. Raise squeegee assembly.

4. Turn off vacuum motor.

Solution and recovery tanks should be emptied after every use.

MAINTENANCE: Unplug from outlet before servicing.

Daily

1. Clean float assembly & squeegee blades.

Monthly

1. Check wear on squeegee blades.

2. Grease rear wheels.

3. Grease pivot points on brush motor assembly.

Every 500 hours check condition of carbon brushes on vacuum motor and

brush drive motor.

Summary of Contents for MC20115

Page 2: ......

Page 9: ...6 ...

Page 11: ...8 ...

Page 13: ...10 ...

Page 15: ...12 ...

Page 17: ...14 ...

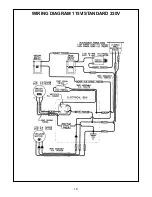

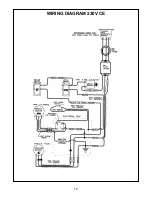

Page 21: ...18 WIRING DIAGRAM 115V STANDARD 230V ...

Page 22: ...19 WIRING DIAGRAM 230V CE ...