7

TROUBLE SHOOTING

1. Inefficient scrubbing - floors are smeared in appearance.

Solution: Use proper type and correct amount of detergent. Replace worn or damaged scrub

attachments. Increase force on scrubbing head.

2. Squeegee streaks.

Solution: Check rear squeegee rubber for imbedded objects, clean; reverse, or replace if worn or

damaged. Make sure scrub solution is being fed onto brush properly. Use more scrubbing solution.

Replace well-worn scrubber attachments.

3. Odor development.

Solution: Inspect and clean thoroughly the vacuum tank, solution tank, squeegee, vacuum motor,

vacuum hose. NOTE: Super Staph-Trole 256 disinfectant cleaner can be helpful in reducing odors.

4. Vacuum not picking up.

Solution: Water lift should be 60-65" with fully charged batteries. Check seals around vacuum motor

and hose connections. Check vacuum tank drain hose and plug to insure seal. Check hoses for

holes. Clean out squeegee inlet and check squeegee rubbers for severe wear. Make sure solution is

properly feeding into scrubhead attachments. Clean and/or repair vacuum motor.

5. Charger malfunction.

Solution: Consult maintenance and repair data contained in brochure herewith for detailed information.

In general, make sure charger is put in upright position when charging - this helps keep unit cool. Do

not cover charger when it is in use. Make sure connectors on inlet and outlet cords are not broken.

Check AC input voltage – it should be 110 volts, 120 volts, maximum. Replace faulty fuses, ammeter,

timer, or other components, when necessary.

6. Use cycle too short.

Solution: Check voltage on batteries after full charging; output voltage should be 43-45 volts with

specific gravity at 1.260-1.265. Check battery electrolyte level. Check for loose or corroded battery

leads and connections. Replace batteries that will not hold a charge. Lubricate casters. Reduce

scrubbing pressure. Check brushes on motors, especially on vacuum motor. Replace brushes on

motors when needed. Test charger for output, it may need repair.

7. Motors will not start or run.

Solution: Check battery leads and connection for corrosion and looseness; correct if required. Check

switches for proper contacting; replace if required. Check motor brushes; replace brushes or motors

if required.

8. Speed control does not function.

Solution: The speed control has built-in protection to guard against reversed connections, check

battery connections. Machine locked in high or low speed. Inspect entire speed control for burn

marks of components that have broken. These would be caused by a direct short in the circuit.

Replace entire control as needed.

Summary of Contents for Powerboss PB32036CE

Page 2: ......

Page 11: ...8 ...

Page 15: ...12 ...

Page 17: ...14 ...

Page 19: ...16 ...

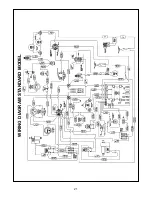

Page 24: ...21 WIRING DIAGRAM STANDARD MODEL ...

Page 25: ...22 WIRING DIAGRAM CE MODEL ...