Summary of Contents for SCV28

Page 1: ...SCV 28 32 RIDER SCRUBBER OPERATION SERVICE PARTS CARE ...

Page 3: ...3 ...

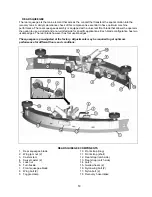

Page 31: ...EXPLODED VIEWS MAIN ASSEMBLY I 25 ...

Page 32: ...26 ...

Page 33: ...MAIN ASSEMBLY II 27 ...

Page 34: ...28 ...

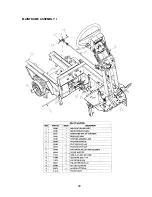

Page 35: ...MAINFRAME ASSEMBLY I 29 ...

Page 36: ...MAINFRAME ASSEMBLY II 30 ...

Page 37: ...31 ...

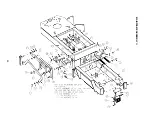

Page 38: ...FRONT DRIVE ASSEMBLY 32 ...

Page 39: ...33 ...

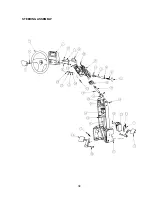

Page 40: ...STEERING ASSEMBLY 34 ...

Page 41: ...35 ...

Page 42: ...LCD HOUSING ASSEMBLY 36 ...

Page 43: ...SOLUTION TANK ASSEMBLY 37 ...

Page 44: ...38 ...

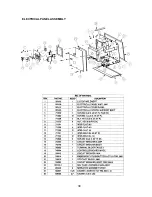

Page 45: ...ELECTRICAL PANEL ASSEMBLY 39 ...

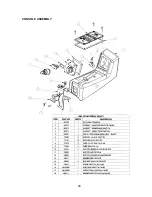

Page 46: ...CONSOLE ASSEMBLY 40 ...

Page 47: ...RECOVERY TANK ASSEMBLY I 41 ...

Page 48: ...42 ...

Page 49: ...RECOVERY TANK II 43 ...

Page 50: ...DIVERTER ASSEMBLY 44 ...

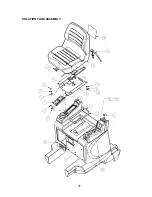

Page 51: ...BATTERY BOX ASSEMBLY 45 ...

Page 52: ...PUMP ASSEMBLY 46 ...

Page 53: ...47 ...

Page 54: ...REAR AXLE ASSEMBLY 48 ...

Page 55: ...SQUEEGEE MECHANISM ASSEMBLY 49 ...

Page 56: ...REAR SQUEEGEE ASSEMBLY 28 50 ...

Page 57: ...51 ...

Page 58: ...REAR SQUEEGEE ASSEMBLY 32 52 ...

Page 59: ...53 ...

Page 60: ...28 CYLINDRICAL SCRUB DECK ASSEMBLY 54 ...

Page 61: ...55 ...

Page 62: ...28 DISC SCRUB DECK ASSEMBLY 56 ...

Page 63: ...57 ...

Page 64: ...32 CYLINDRICAL SCRUB DECK ASSEMBLY 58 ...

Page 65: ...59 ...

Page 66: ...32 DISC SCRUB DECK ASSEMBLY 60 ...

Page 67: ...61 ...

Page 68: ...CYLINDRICAL DECK AND SIDE SQUEEGEE MOUNTING 62 ...

Page 69: ...63 ...

Page 70: ...DISC SCRUBDECK AND SIDE SQUEEGEE MOUNTING 64 ...

Page 71: ...65 ...

Page 72: ...28 SIDE SQUEEGEE RIGHT SIDE 66 ...

Page 73: ...28 SIDE SQUEEGEE LEFT SIDE 67 ...

Page 74: ...32 SIDE SQUEEGEE RIGHT SIDE 68 ...

Page 75: ...32 SIDE SQUEEGEE LEFT SIDE 69 ...

Page 76: ...OFF AISLE WAND ASSEMBLY 70 ...

Page 77: ...71 ...

Page 78: ...PLUMBING DIAGRAM 72 ...

Page 79: ...WIRING DIAGRAMS POWER WIRING 73 ...

Page 80: ...INPUTS TO CONTROLLER 74 ...

Page 81: ...OUTPUTS FROM CONTROLLER 75 ...

Page 82: ...KEYBOARD WIRING 76 ...

Page 83: ...MACHINE SCHEMATIC 77 ...

Page 84: ...1 03 78 ...