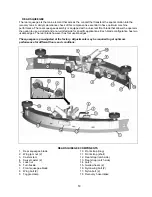

MECHANICAL & PARKING BRAKE

Located on the left side of the operator compartment on the floor is the mechanical brake which doubles as

the parking brake. Even though the machine is equipped with a regenerative braking system, the

mechanical brakes can be activated by pushing down on the pedal and apply brakes on the rear wheels.

The mechanical brake also doubles as a

Parking brake

. To set the parking brake, press down on the brake

pedal as far down as possible; then, engage the

parking brake lever

teeth with the brake pedal tab by

rotating the lever clockwise. This will keep the brakes on the rear wheels. To disengage the parking brake,

simply push down on the brake pedal until the parking brake lever disengages itself from the pedal tab.

Another safety feature on the machine is the

Electro-magnetic brake

built-in on the traction drive motor.

When the machine’s power is turned off (using either the key or the emergency button), the

E-mag

brake is

activated and the traction motor is prevented from moving.

The mechanical /parking brake system is self-cleaning and periodic use is recommended to avoid

build up of foreign matter that may cause seizing in the mechanism and rust build up.

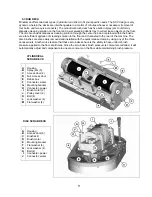

EMERGENCY DISCONNECT BUTTON

This button is located in the middle of the electrical panel that is

directly underneath the operator’s seat. When the

red

emergency

button is pressed, power will be turned off. Use this button in case of

a machine emergency. The red knob needs to be raised in order to

run the machine. To reactivate, turn the knob as shown by the arrow

on the switch and the button will pop up.

All operational settings are

retained even when the power is turned off and on.

CIRCUIT BREAKERS

The circuit breakers are located next to the emergency disconnect

button. The

6-amp breaker

(indicated by white arrow). This breaker

protects all auxiliary circuits on the machine (headlights, horn, and

back-up alarm). The

100-amp breaker

(indicated by black arrow)

protects the main system circuit (controller). Each main component is

individually protected with an internal breaker built-in the controller.

(See fault code table) and can be reset by turning the key switch off a

few seconds and then on again.

9

Summary of Contents for SCV28

Page 1: ...SCV 28 32 RIDER SCRUBBER OPERATION SERVICE PARTS CARE ...

Page 3: ...3 ...

Page 31: ...EXPLODED VIEWS MAIN ASSEMBLY I 25 ...

Page 32: ...26 ...

Page 33: ...MAIN ASSEMBLY II 27 ...

Page 34: ...28 ...

Page 35: ...MAINFRAME ASSEMBLY I 29 ...

Page 36: ...MAINFRAME ASSEMBLY II 30 ...

Page 37: ...31 ...

Page 38: ...FRONT DRIVE ASSEMBLY 32 ...

Page 39: ...33 ...

Page 40: ...STEERING ASSEMBLY 34 ...

Page 41: ...35 ...

Page 42: ...LCD HOUSING ASSEMBLY 36 ...

Page 43: ...SOLUTION TANK ASSEMBLY 37 ...

Page 44: ...38 ...

Page 45: ...ELECTRICAL PANEL ASSEMBLY 39 ...

Page 46: ...CONSOLE ASSEMBLY 40 ...

Page 47: ...RECOVERY TANK ASSEMBLY I 41 ...

Page 48: ...42 ...

Page 49: ...RECOVERY TANK II 43 ...

Page 50: ...DIVERTER ASSEMBLY 44 ...

Page 51: ...BATTERY BOX ASSEMBLY 45 ...

Page 52: ...PUMP ASSEMBLY 46 ...

Page 53: ...47 ...

Page 54: ...REAR AXLE ASSEMBLY 48 ...

Page 55: ...SQUEEGEE MECHANISM ASSEMBLY 49 ...

Page 56: ...REAR SQUEEGEE ASSEMBLY 28 50 ...

Page 57: ...51 ...

Page 58: ...REAR SQUEEGEE ASSEMBLY 32 52 ...

Page 59: ...53 ...

Page 60: ...28 CYLINDRICAL SCRUB DECK ASSEMBLY 54 ...

Page 61: ...55 ...

Page 62: ...28 DISC SCRUB DECK ASSEMBLY 56 ...

Page 63: ...57 ...

Page 64: ...32 CYLINDRICAL SCRUB DECK ASSEMBLY 58 ...

Page 65: ...59 ...

Page 66: ...32 DISC SCRUB DECK ASSEMBLY 60 ...

Page 67: ...61 ...

Page 68: ...CYLINDRICAL DECK AND SIDE SQUEEGEE MOUNTING 62 ...

Page 69: ...63 ...

Page 70: ...DISC SCRUBDECK AND SIDE SQUEEGEE MOUNTING 64 ...

Page 71: ...65 ...

Page 72: ...28 SIDE SQUEEGEE RIGHT SIDE 66 ...

Page 73: ...28 SIDE SQUEEGEE LEFT SIDE 67 ...

Page 74: ...32 SIDE SQUEEGEE RIGHT SIDE 68 ...

Page 75: ...32 SIDE SQUEEGEE LEFT SIDE 69 ...

Page 76: ...OFF AISLE WAND ASSEMBLY 70 ...

Page 77: ...71 ...

Page 78: ...PLUMBING DIAGRAM 72 ...

Page 79: ...WIRING DIAGRAMS POWER WIRING 73 ...

Page 80: ...INPUTS TO CONTROLLER 74 ...

Page 81: ...OUTPUTS FROM CONTROLLER 75 ...

Page 82: ...KEYBOARD WIRING 76 ...

Page 83: ...MACHINE SCHEMATIC 77 ...

Page 84: ...1 03 78 ...