Introduction

Please be advised explicitly that

we cannot accept any legal is-

sues out of the contents of this

manual.

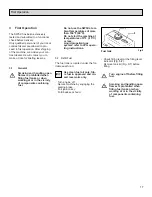

If repair work has to be perfor-

med make sure that only genui-

ne spare parts are used; only

genuine spare parts may gua-

rantee a dependable machine.

Valid as of: March 2005

Dear customer,

It is our desire that the good cha-

racteristics of the SW5X should

justify the confidence you demon-

strated by making this purchase.

Before first operation of your

SW5X, read these instructions

carefully. The manual provides

valuable information about opera-

tion, service and maintenance.

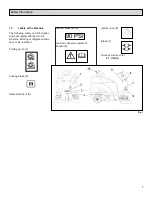

The symbol as used in this manual

identifies items relevant to safety.

Please observe the safety provi-

sions (see chapter 1).

Before first operation of the machine,

read these instructions and safety in-

formation carefully and comply with

them.

2

Summary of Contents for SW5X PB40PH

Page 1: ...SW5X Model PB40PL PB40PH Instruction Manual ...

Page 62: ...62 8 Spare parts ...

Page 64: ...64 ...

Page 66: ...66 ...

Page 68: ...68 ...

Page 70: ...70 ...

Page 72: ...72 ...

Page 74: ...74 ...

Page 76: ...76 ...

Page 78: ...78 ...

Page 80: ...80 ...

Page 82: ...82 ...

Page 84: ...84 ...

Page 86: ...86 ...

Page 88: ...88 ...

Page 90: ...90 ...

Page 92: ...92 ...

Page 94: ...94 ...

Page 96: ...96 ...

Page 98: ...98 ...

Page 100: ...100 ...

Page 102: ...102 ...

Page 104: ...104 ...

Page 106: ...106 ...

Page 108: ...108 ...

Page 110: ...110 ...

Page 112: ...112 ...

Page 114: ...114 ...

Page 116: ...116 ...

Page 118: ...118 ...

Page 120: ...120 ...

Page 122: ...122 ...

Page 123: ...Set of tires Pos Part No Description 1 99652900 Set of pneumatic tyres 123 ...

Page 124: ...124 ...

Page 126: ...126 ...

Page 128: ...128 ...

Page 130: ...130 ...

Page 132: ...132 ...

Page 134: ...134 ...

Page 136: ...136 ...

Page 138: ...138 ...

Page 140: ...140 ...

Page 144: ......