14. Maintenance

MiR250 Shelf Carrier User Guide (en) 03/2021 - v.1.4 ©Copyright 2021: Mobile Industrial Robots A/S.

224

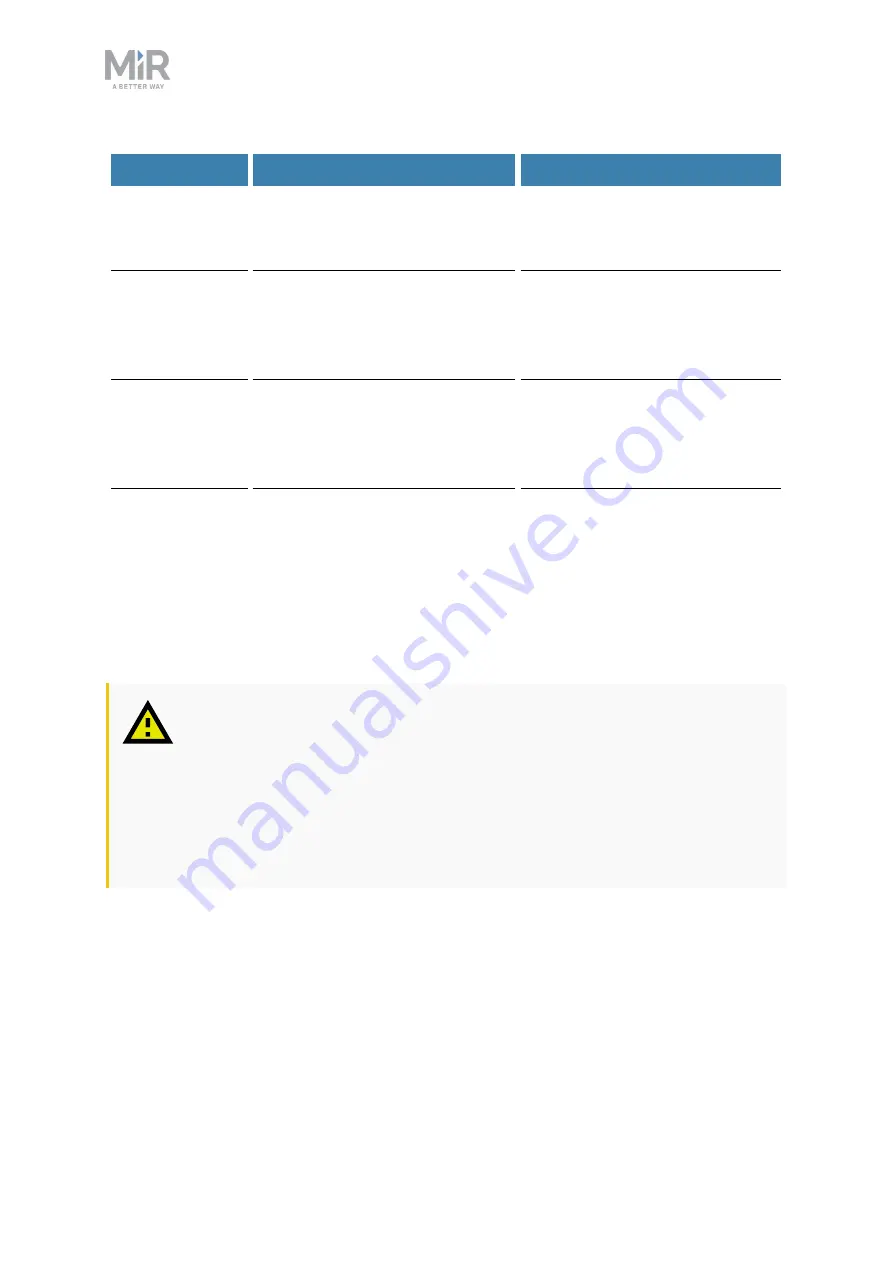

Part

Maintenance

Interval

Safety marking

on the floor

Check if the safety markings

around operating hazard zones

are intact and visible.

Check every six months, and

replace as needed.

Safety stickers

and nameplate

Check if the safety stickers,

identification label, and

nameplate on the robot are still

intact and visible.

Check every six months, and

replace as needed.

Shelf carrier

actuators and

lifting

mechanism

Check that the carrier pins can

be raised and lowered smoothly

and completely.

Check every six months, and

replace as needed.

MiR Shelf

Carrier 250

Emergency stop

buttons

To check that the Emergency

stop buttons work, push a button

and check that the status light

turns red and that the robot

continues to be in Emergency

stop until you press the Resume

button.

Every three to four months

according to

EN/ISO 13850

Safety of machinery - Emergency

stop function

.

CAUTION

If the robot has been impacted, it may be structurally damaged, causing a risk

of malfunction and injury to personnel.

•

If you suspect the robot has suffered any damage, you need to conduct a

thorough inspection to ensure that the robot's strength and structure is not

compromised.

14.3 Battery maintenance

The battery is generally maintenance-free but should be cleaned if it gets very dirty. Before

cleaning, the battery must be removed from any power source. Only use a dry and soft cloth

to clean the housing of the battery, and do not use abrasives or solvents.

For storage of the battery, see

.