www.mirabelleproducts.com

7

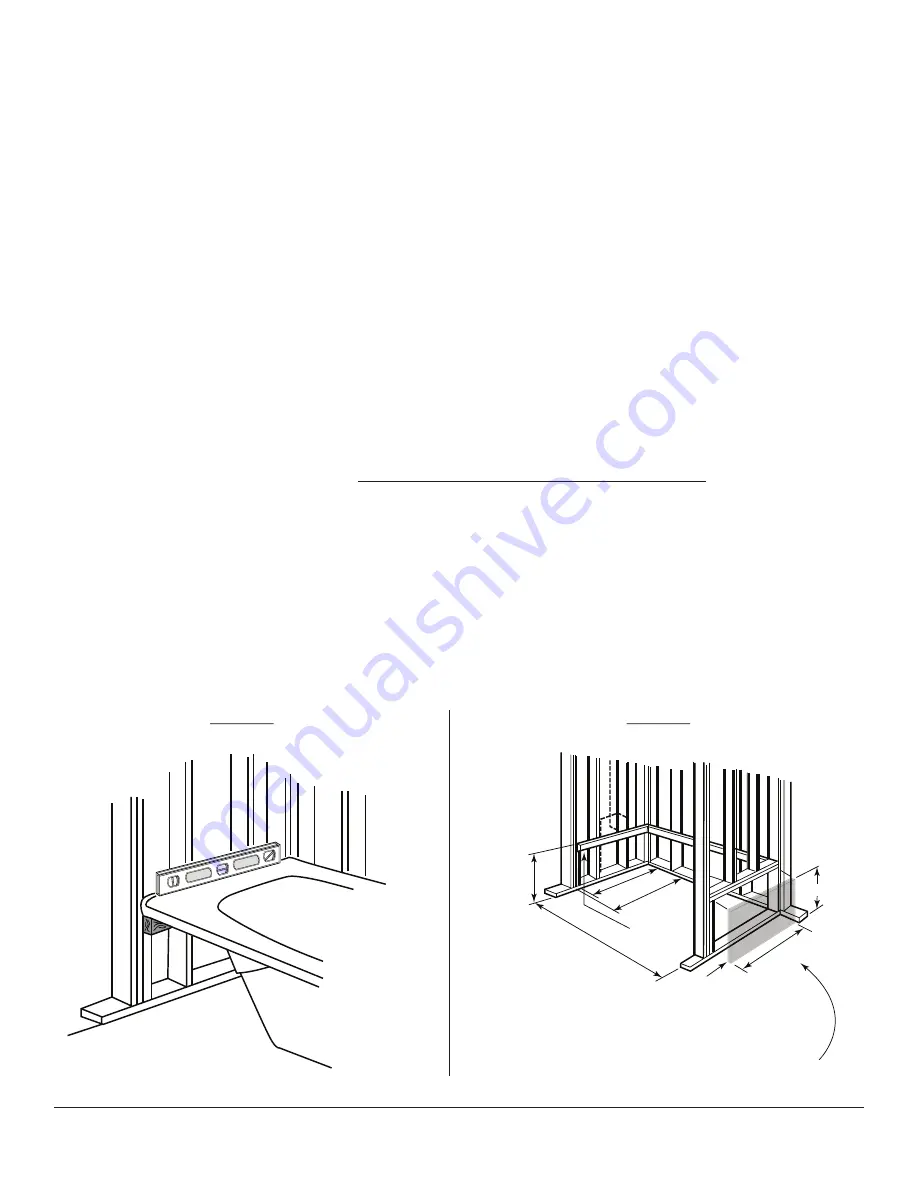

Framing and Installation

Structural measurements should be verified against the actual bath received to ensure proper fit.

• Never lift the tub by the plumbing. Doing so can result in leaks.

• Check if the floor is level and of good quality. An uneven floor may impede proper installation of the tub.

• Clean installation area of any debris or trash.

Locate studs as needed. Ensure roughing-in dimensions are proper, plumb and square. Provisions must be made in all installations for an

access opening for servicing the pump and controls on the pump or blower side.

An access opening of at least 18’’ x 24’’ must be provided or warranty service will not be performed. It is strongly recommended that an

additional opening be provided for access to the drain components.

The apron should not be used as the primary access opening.

If the subfloor is not level, you must level the entire surface prior to installing the bathtub.

Ensure that the entire floor is level and can support a load of 80lbs. per square foot.

The bathtub must remain level in order for it to drain properly and must make contact with the leveling material.

1. Position the tub into the installation opening and level the deck in both directions, shimming the base of the tub if necessary. Mark the final

position of the underside of the deck by tracing a line on to the studs (see Figure 1).

2. Remove the tub and attach a 1 x 4 stringer to the studs, with the top of the stringer touching the traced line. Never support the tub by its

deck lip or stringers (see figure 2).

3. Install drain components to the tub following the drain installation instructions. Note that this requires a cutout in the floor. Before replacing

your tub for final installation, bathtubs require a 6’’ x 12’’ floor opening for the 1-1/2” drain and waste & overflow kit. The drain/overflow of

the bath extends below the bottom of the bath.

The bath must be supported along its entire bottom. Do not remove foam base & pad from the bottom of the tub. Use 1-1/2’’ to 2’’ of mortar

as bedding material (do not use sand or foam). After the mortar has been poured, and before it sets, position tub within recess until the rim is

leveled against the leveling stringers (see below).

FIGURE 1

STRINGER INSTALLATION

TYPICAL DROP-IN TYPE INSTALLATION

REFERENCE FOR DROP-IN INSTALLATION

FIGURE 2

TYPICAL ALCOVE INSTALLATION

18"

(457.2mm)

24"

(609.6mm)

24"

(609.6mm)

LEVELING

STRINGERS

ACCESS PANEL MUST BE LOCATED

ON THE SAME SIDE AS THE MOTOR.

ALLOW OPEN FRAMING ON

PUMP MOTOR END FOR SERVICE.

ACCESS PANELS NOT REQUIRED

FOR NON-SYSTEM TUBS.

NOTE:

FRONT EDGE OF BATH

MUST BE SUPPORTED

BY STUD WALL.

HEIGHT

TO LIP

TILE

WALLBOARD

G

CUTOUT

18"

(457.2MM)

AS DESIRED

MOUNTING

SURFACE

WATERPROOF

SEALANT

BATH

AS DESIRED

F

CUTOUT

C

SILICONE

1" X 4" JOIST

STUD

AIR GAP 1/4" OR MORE

UNLESS AS ACCESS OPENING OF AT LEST 18" X 24"

IS PROVIDED, WARRANTY SERVICE WILL NOT BE PERFORMED.

ACCESS PANEL MUST BE LOCATED

ON THE SAME SIDE AS THE MOTOR.

ALLOW OPEN FRAMING ON

PUMP MOTOR END FOR SERVICE.

ACCESS PANELS NOT REQUIRED

FOR NON-SYSTEM TUBS.

UNLESS AS ACCESS OPENING OF AT LEST 18" X 24"

IS PROVIDED, WARRANTY SERVICE WILL NOT BE PERFORMED.

E

C

D

W