An external emergency stop circuit is recommended.

Before running the tool

Before starting the tool, check that the tool is mounted properly and ensure that the motor drive is installed

properly.

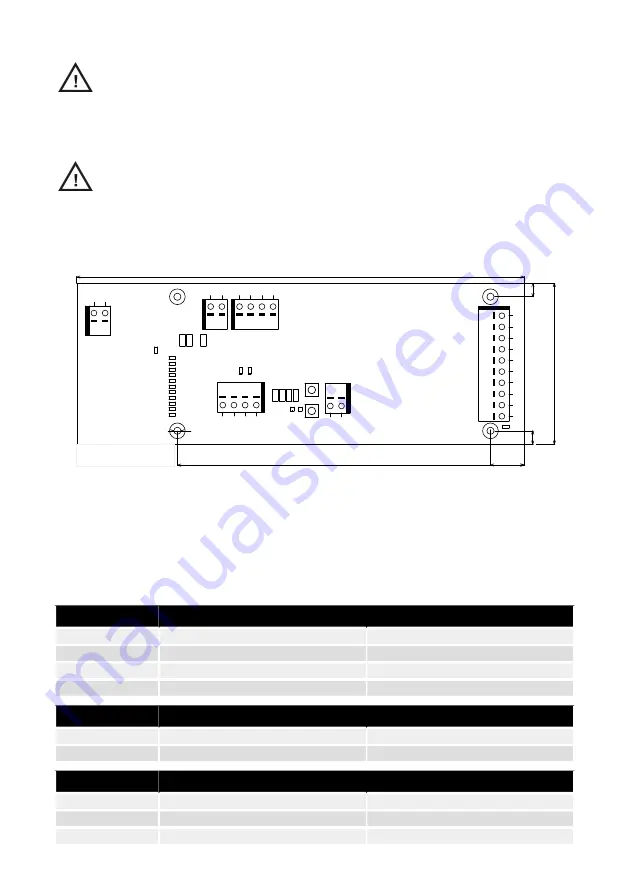

Motor drive overview

Motor drive PCB connectors, buttons, jumpers, indicators, mounting holes and dimensions

B

J

3

J

P1

3

J

P1

5

J4

D17

D21

NTC+

N

O

D26

D2

D18

D3

D19

D20

D23

D24

GND

J6

1

5

V

A

D

I4

GND

D

I2

J

P3

J

P4

J5

D

I1

D

4

J

P2

J

P1

S2

S1

GND

155

D36

P+

C+

P-

GND

NTC-

7

2

D22

D25

J

P1

2

G

N

D

J1

D

3

0

D

1

4

J2

C-

PhaseB

C

O

M

D

I3

200

48V

15

6

PhaseA

PhaseC

6

ø 3,20

D

2

9

Dimensions specified in

millimeters.

The motor drive PCB comes mounted in a DIN-rail holder that can be attached to a standard 35 x 7.5mm EN50022 DIN-rail,

but the motor drive PCB can be removed from this holder and mounted using the mounting holes instead. If the mounting

holes are used, then it is recommended to use 20 mm metal standoffs and 10 mm M3 screws when mounting the motor

drive PCB.

It is recommended to use 10 mm ferrules with plastic sleeve for each wire that is attached to any of the connectors. The

wires can then easily be pushed into the connectors and released with the help of a small flat-head screwdriver (3.5 mm

blade width, 0.6 mm blade thickness).

Connector description

Description

PIN

Connector

GND

GND

J1

Modbus RTU RS-485 (A)

A

J1

Modbus RTU RS-485 (B)

B

J1

GND

GND

J1

Description

PIN

Connector

GND

GND

J2

48 VDC input

48V

J2

Description

PIN

Connector

P+

P+

J3

C+

C+

J3

C-

C-

J3

6

en (original)