5

3

3

1

1

2

2

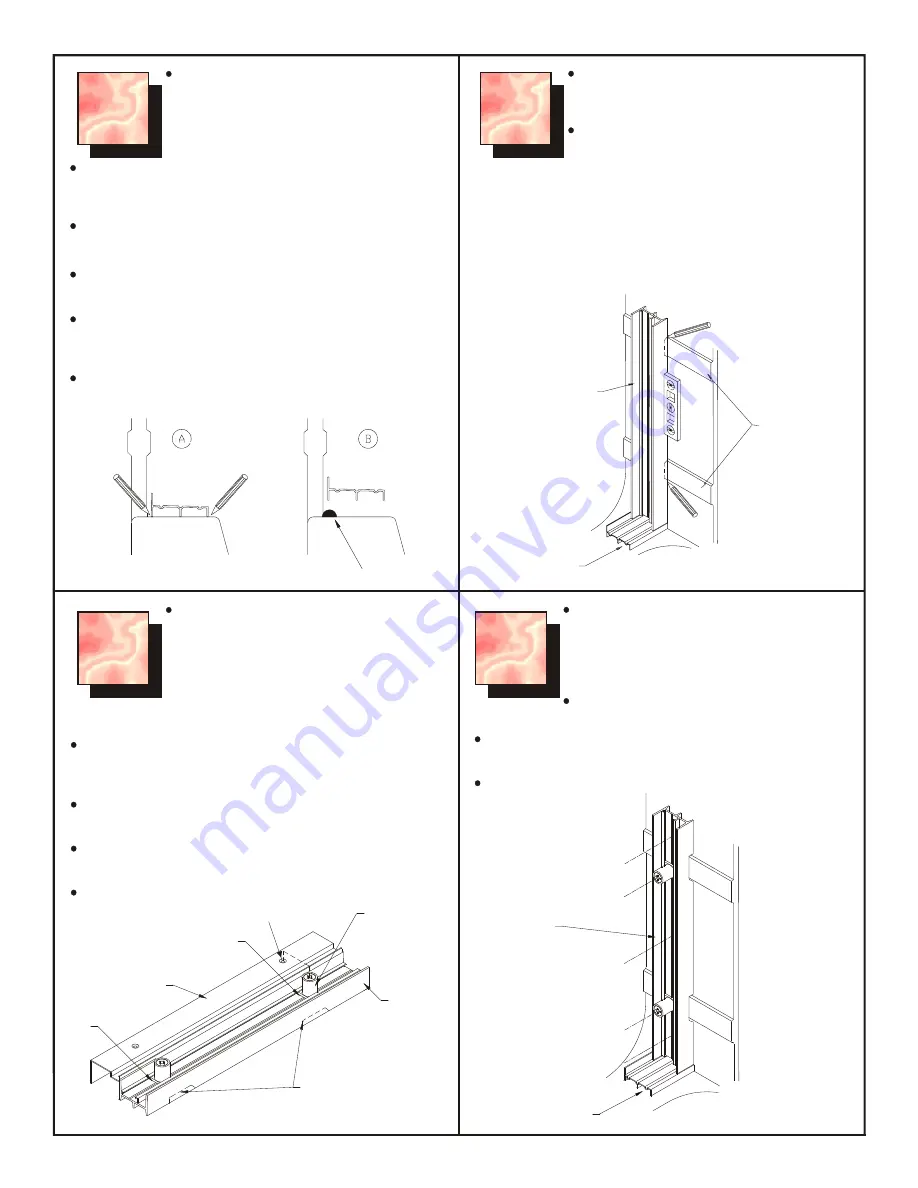

Position the plastic jambs against the wall

according to the position as shown ensuring

that the flexible fins are against the tub wall.

Plumb with level and pencil mark as shown.

4

4

(Note: Not applicable for M36, M37, M41 & 360 installation.

Reposition the plastic jamb and drill three 1/8”

(3 mm) holes through the plastic wall jamb and

shower wall. The holes should be spaced

along the jamb and drilled as perpendicular to

the wall as possible.

Check that the adjusting blocks are in the

marked position.

Carve out, with a knife the three fins on the

rear side of each plastic jamb in order that it

may fit the contour of the raised bands of the

acrylic tub/shower or shower stall.

(Not applicable to fiberglass products,

model #s: 314836AC, 374835A, 326032A,

376032B, M41 & 360 Series door

installation).

Slide the adjustment blocks (T-12) into each end of the plastic

jambs (T-7). Be sure that the adjustment screws are all the way

into the adjustment blocks.

Lay one plastic jamb (T-7) and an aluminum wall jamb (T-2)

side by side on a flat surface.

Align the adjusting blocks (T-12) with the prepunched holes in

the aluminum jamb. Mark the location of the adjusting blocks.

Repeat with the other plastic jamb and aluminum wall jamb.

Depending on the location of the shower head,

determine which way to position the

interchangeable panels (T-4, T-5, T-6), wall

jambs (T-2) and plastic jambs (T-7). See

Figures 1, 2, 3 or 4.

NOTE:

Only for the M160/M360 and 360 Series door

installation: measure the wall opening at the tub rim and cut the

sill (T-3) to suit the full width of the tub.

Place the sill (T-3) on the rim of the tub/shower or shower stall,

in line and closer to the inner edge of the rim.

Draw a pencil line (A) along the outside and inside of the sill,

then remove the sill.

Apply a bead of silicone caulking(B) along the outside pencil

line. Press the sill onto the base in the original position using

the inside pencil line as a guide.

Remove excess silicone.

Drill a 1/8” (3 mm) hole through each adjusting block, the

plastic jamb and the shower wall.

Drill the holes as perpendicular as possible.

PENCIL

PENCIL

SILICONE

T-3

SILL

T-7

PLASTIC

JAMB

OUTSIDE

RAISED

BANDS

INSIDE TUB

PENCIL MARK

T-2

WALL JAMB

PENCIL MARK

T-12

ADJUSTMENT

BLOCK

T-7 PLASTIC

JAMB

CARVE OUT

DRILL

DRILL

DRILL

DRILL

DRILL

T-3

SILL

OUTSIDE

INSIDE TUB

T-7

PLASTIC

JAMB

LEVEL

PREPUNCHED HOLE