Page 3 - 8

Save manual for future reference.

PREPARATION

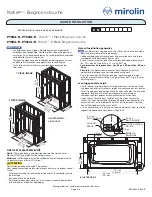

Build solid framing to the dimensions in Figure 1.

Ensure that the floor is level, correct if necessary.

The drain location on the tub shower is shown but actual installation will depend on waste/overflow which is purchased.

Drain pipe must be vertical.

Trim drain pipe as required to meet drain assembly.

Place the unit into position and plumb vertical, shim if necessary.

Dry fit drain to check position.

Mark and drill 3/16” pilot holes for plumbing fixtures.

Verify that the holes are in the right location.

From the finished side of the unit use the correct size hole saw to cut the openings, using the pilot holes as guides.

INSTALLATION

Carefully position the Tub Shower into the framing and push flush against the framework walls.

Install the drain according to the manufacturer’s instructions. Use a mildew resistant silicone bathroom caulking to seal the drain to the top surface of

the tub.

Marked by dimple holes along the flanges drill 3/16” hole on each dimple, 7 on each side flanges and 2 across the top flange. Refer to Figure 3.

Fasten the acrylic unit to the framing using drywall screws.

Over tightening or burying the head of the screw will cause the acrylic to crack

Make sure that the unit is plumbed before fastening.

Apply silicone caulking over the head of the screws and around the openings for the fittings when they are installed.

TROUBLESHOOTING

Excessive gaps at the seams in the back corners: Shim front post of lower section as illustrated in Figure 3B.

Tub bottom section is not level: Refer to shimming section on page 1.

Water remains around the bathrim or drain: Check that the installation is level and that the tub sits firmly on its base; use wood shim to correct.

FINISHING

Apply trim around the tub shower periphery to finish drywall, if required.

Install the tub shower door according to the manufacturer’s instructions if purchased.

INSTALLATION CLEAN-UP

Remove construction dirt and residue with a mild liquid detergent.

DO NOT USE

abrasive cleaners, scouring compounds and pads, metal scrapers, steel wool, or other materials that could damage or dull

the surface of the bath.

Remove plaster carefully with a blunt wooden block having rounded edges.

Remove paint and other stubborn stains with isopropyl (rubbing) alcohol.

DO NOT USE

products such as acetone (nail polish remover), dry cleaning solution, lacquer thinners, gasoline, pine oil, etc.

TESTING

Test the installation after completing the plumbing, but before enclosing the bath and finishing the surroundings.

Fill the bath with water and leave it for one hour to ensure that the adjustment of the drain-overflow assembly is correct, and that there are no leaks.

Mirolin Industries Corp. is not responsible for any damages incurred as a result of poor installation of the product.

MAINTENANCE

The acrylic sheet, which forms the surface of your bathtub, provides one of the most durable surfaces found in modern bathrooms. Keep it bright and

smooth with mild liquid household detergent, soap and water, or foaming cleansers.

NEVER USE

aromatic solvents, abrasive cleaners, scouring compounds or pads, strong liquid cleansers, or other material that could

damage or dull the surface of the bath.

Restoring Surface Gloss

Restore surface gloss by applying a very fine rubbing compound and polishing the surface by hand or with a power buffer. Finish with an application of a

good quality automotive wax.

Minor Repairs to Surface

Remove minor scratches and scuffs as follows. First, wet sand the area with 600 grit wet sandpaper until the surface is smooth. Then, restore the gloss as

described under

RESTORING SURFACE GLOSS

.

NOTICE

CAUTION

CAUTION

NOTICE

CAUTION

R0084314, Rev B