English –

15

English

Additional pairs of photocells can be installed at any time on a system for sliding gates.

Up to a maximum of 6 pairs of photocells with safety functions can be added (as shown in the example

A-B-C-D-E-F

in

fig. 31) and 1 pair

with

a control function (as shown in the example

G

in

fig. 31

) which performs an

Opening

manoeuvre only.

For the correct location of these pairs of photocells, refer to

fig. 31

.

In order for the control unit to recognise each pair of photocells and the specifically assigned function, the devices must be assigned with

addresses by the insertion of one or two electric jumpers (

Table 2

) or no jumper at all (

Table 2

). In this way when the control unit receives the

input from the photocells it will activate the motor for the corresponding manoeuvre.

The address assignment procedure is performed both on the TX and RX photocell as follows:

For photocells “

A-B-C-D-E-F

”

Take care to observe the following warnings:

•

the electric jumpers must be positioned on the two elements making up the pair of photocells (TX and RX) in the same position;

• the same configuration used on one pair of photocells must NOT be used on other photocells.

To program these pairs of photocells (if fitted on the system) proceed as follows:

01.

Open the cover of the photocell.

02.

In

fig. 31

locate the position in which the specific photocells are installed.

03.

In

Table 2

select the required configuration and insert electric jumpers in the two photocells.

For photocells “

G

”

Take care to observe the following warnings:

• These photocells have a different function from the other (controlling the automation), and therefore must be positioned at a specific distance

to avoid possible interference.

• These photocells remain powered also when the automation is on standby and in the event of a power failure, if the buffer battery is fitted, this

will reduce the standard lifetime (see STEP

6.5

).

To program these pairs of photocells (if fitted on the system) no electric jumper must be inserted (

see Table 2

).

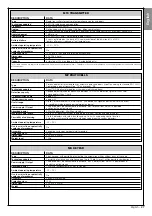

SELECTING THE PHOTOCELL PAIR OPERATING MODE

TABLE 2

Pair of photocells

Electric jumpers

A

Photocells h = 50 cm

(these are activated when

the gate is in the Closing phase)

B

Photocells h = 100 cm

(these are activated when

the gate is in the Closing phase)

C

Photocells h = 50 cm

(these are activated when

the gate is in the Opening

or Closing phase)

D

Photocells h = 100 cm

(these are activated when

the gate is in the Opening

or Closing phase)

Pair of photocells

Electric jumpers

E

Photocells on right

(these are activated when

the gate is in the Opening phase)

F

Photocells on left

(these are activated when

the gate is in the Opening phase)

G

Gate

opening

only command

31