10

– English

English

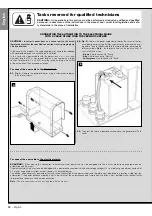

e)

- position one end of the rack above the gearmotor pinion, taking

care to align the first fixing bracket with the centre of the pinion (

fig. 14

).

f)

- using a spirit level, level the first section of the rack in the pinion

area and temporarily secure to the gate leaf by means of adhesive

tape.

Then repeat the same operations on the next section and so on

through the entire length of the rack, taking care to position each

section horizontally and perfectly aligned with the end placed on the

pinion.

g)

- Tighten the fixing brackets fully down on the gate leaf as follows

(

fig. 15

):

first secure the two brackets in the vicinity of the gear-

motor by means of screws and washers (with the gate com-

pletely closed). Then move the gate to bring the next bracket in

alignment with the pinion and secure it to the leaf.

Repeat the same operation for the next bracket and so on until all

brackets on the rack are secured.

Note

– The screws required to fix the rack on the gate leaf are not

included in the pack as their type depends on the material and thick-

ness of the leaf on which they are inserted.

h)

- before securing the last section of the rack, completely open the

gate and check that the bracket on the end is aligned with the centre

of the pinion. If this is not so, move the bracket to this position and, if

necessary, use a hacksaw to cut off the excess section of the rack,

leaving a free section of approx. 5 cm.

IMPORTANT

-

the rack must

not protrude from the gate leaf.

Caution

– At the end of this work, check that the rack is per-

fectly level; the slots on the brackets enable corrections of small

differences in alignment during fixture.

08.

Then secure the gearmotor onto the foundation plate, tightening the

two locknuts fully down:

the pinion must be perfectly aligned with the

rack; if necessary slide the gearmotor forwards or backwards to

adjust.

09.

Release the gearmotor by means of the special release key (see

chapter “

Manually releasing or locking the gearmotor

” in the

“Operation manual”)

and move the gate leaf to mid-travel

.

10.

Make a number of complete manual gate

opening

and

closing

manoeuvres to enable self-adjustment of the mechanical limit

switches.

Important

– During this manoeuvre, ensure that the rack

slides in alignment with the pinion.

11.

Then

move the gate leaf to mid-trave

l and lock the gearmotor

by means of the special key (see chapter “

Manually releasing or

locking the gearmotor

” in the “Operation manual”).

Note

– The 4 stud bolts supplied in the pack must be used exclusively to

adjust the gearmotor height, when deciding to assembly the rack before

the gearmotor (

fig. 16

).

15

12

13

16

14

80 mm

Right-hand positioning of the gearmotor

“Closing”

position

C

80 mm

Left-hand positioning of the gearmotor

“Closing”

position

C