11

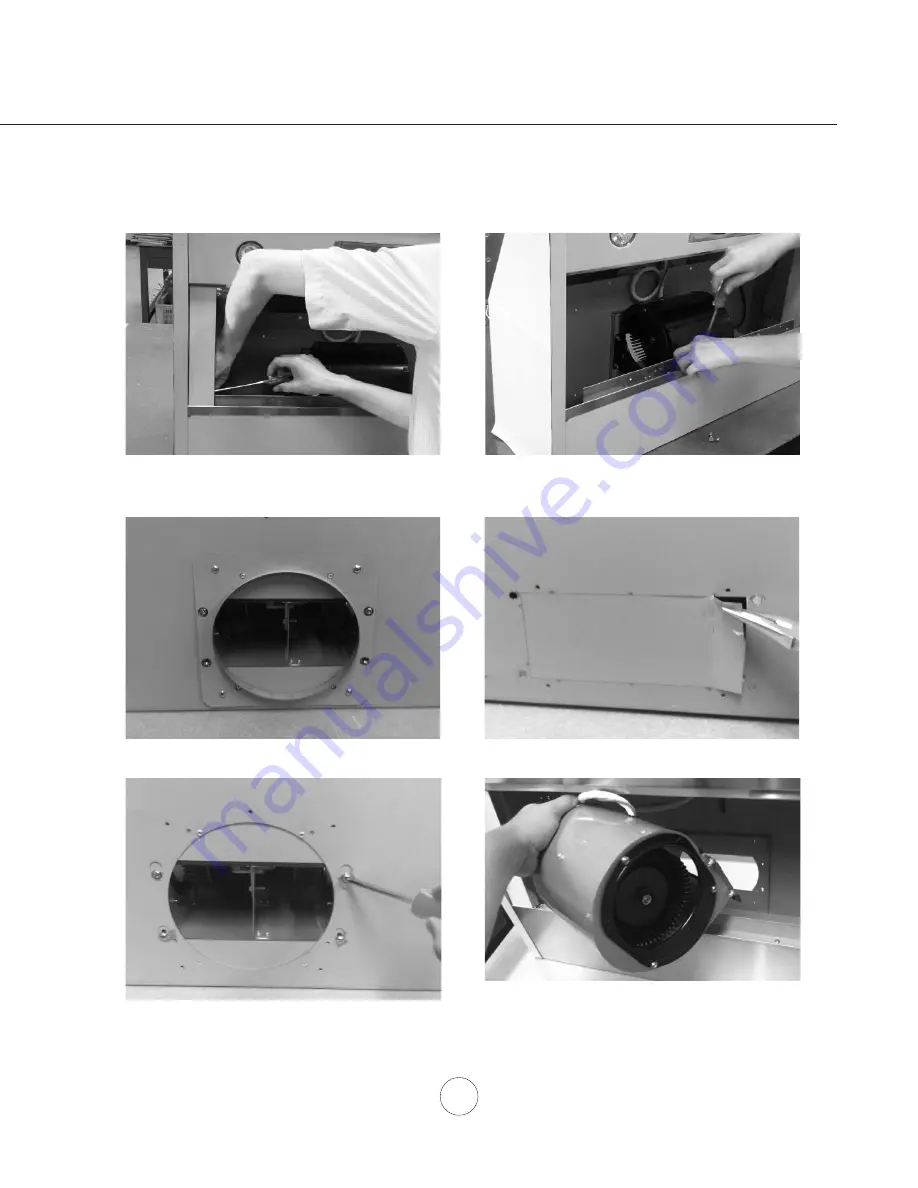

This range hood is equipped standard with a 7” round vertical duct option. To convert from 7” round vertical to

3-1/4” x 10” horizontal ducting please following the instructions below.

VERTICAL TO HORIZONTAL DUCTING CONVERSION

3. Unscrew (4) screws holding 7” round collar from

top of hood body and remove collar.

4. Using plyers, remove rectangular cover plate at

back of hood body.

5. Unscrew (4) screws holding blower to top of hood

body.

6. Remove blower from hood body and turn

blower 180 degrees so that blower outlet faces

the back of hood body.

Installation –

Horizontal Conversion

1. Unscrew (2) screws holding each left and right

side bottom spacer panels and remove panels

from hood body.

2. Unscrew (4) screws holding the rear filter holder

panel and remove panel from hood body.

Summary of Contents for MH70130BS

Page 1: ...2018 SEP MH70130BS MH70136BS MODEL ...

Page 2: ......