Troubleshooting

14

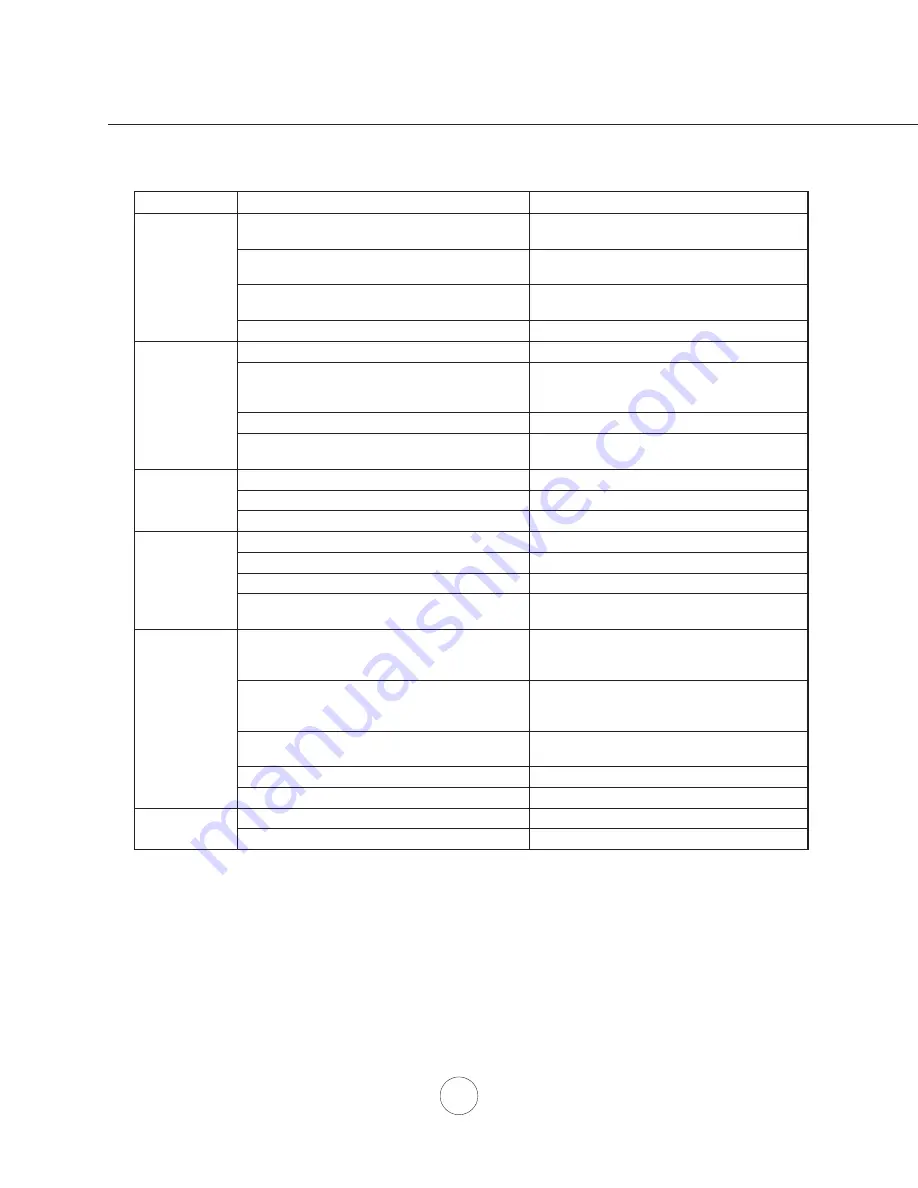

TROUBLESHOOTING PROCEDURES FOR MH702

Issue

Cause

What to do

After installation,

the unit doesn’t

work.

1. The power source is not turned ON.

1. Make sure the circuit breaker and the unit’s

power is ON.

2. The power line and the cable locking connector

is not connecting properly.

2. Check the power connection with the unit is

connected properly.

3. The wires on rotary switch are loose.

3. Make sure the wires on the switch are

connected properly.

4. The switch is defective.

4. Change the switch.

Light works, but

blower is not

turning.

1. The blower is defective, possible seized.

1. Change the blower.

2. The thermally protected system detects if the

blower is too hot to operate and shuts the blower

down.

2. The blower will function properly after the

thermally protected system cool down.

3. Damaged capacitor.

3. Change the capacitor.

4. The blower wire is not connected.

4. Make sure the blower wire is plugged into the

molex connector.

The unit is

vibrating.

1. The blower is not secure in place.

1. Tighten the blower in place.

2. Damaged blower wheel.

2. Change the blower.

3. The hood is not secured in place.

3. Check the installation of the hood.

The blower is

working, but the

lights are not.

1. The light bulb plug is disconnected.

1. Check the light bulb plug connection.

2. Defective halogen bulb.

2. Change the halogen bulb.

3. The light bulb is loose.

3. Tighten the light bulb.

4. The wires on the switch are loose.

4. Make sure the wires on switch are connected

properly.

The hood is

not venting out

properly.

1. The hood might be hanging to high from the

cook top.

1. Adjust the distance between the cook top and

the bottom of the hood within 24” and 36”

range.

2. The wind from the opened windows or opened

doors in the surrounding area are affecting the

ventilation of the hood.

2. Close all the windows and doors to eliminate

the outside wind flow.

3. Blockage in the duct opening or duct work.

3. Remove all the blocking from the duct work or

duct opening.

4. The direction of duct opening is against the wind. 4. Adjust the duct opening direction.

5. Using the wrong size of ducting.

5. Change the ducting to correct size.

Metal filter is

vibrating.

1. Metal filter is loose.

1. Change the metal filter.

2. Spring clip is broken.

2. Change the spring clip.