14

Inspect the working area where the hoist will

be operating:

• Check that there are no obstacles in the way of the

hook during lifting.

• For a hoist with trolley, make sure that travel and

lifting movements are free from obstacles and are

not dangerous to people, things and the workplace.

• Make sure that no permanent working activities are

performed under the operating area of the trolley.

Provide suitable test weights for dynamic and

static load tests, with suitable sling and lifting

equipment, as follows:

3. INSTALLATION INSTRUCTIONS

3.1 PREPARATION FOR INSTALLATION

Before starting installation, make sure the

technical data of the hoist and the parts to be

prepared by the user comply with the content

of the order confirmation, in order to ensure a

proper installation, especially:

Verify the suitability of the rail or the fixed

support to hold the hoist, as well as the feeding

line.

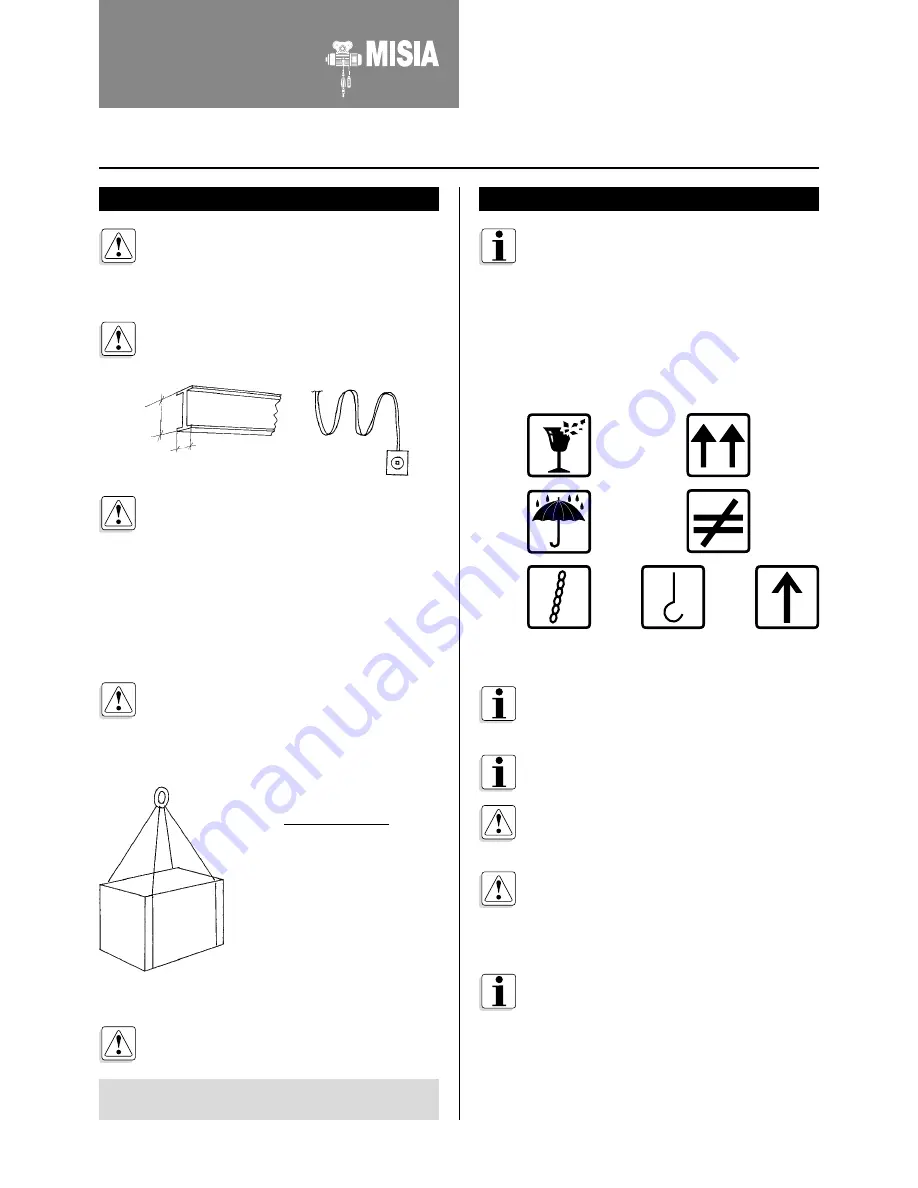

3.2 PACKAGE

Check in the packaging-list, or the delivery

note, the list of documents supplied with the

equipment (including the instruction, operation

and maintenance manual, the various certificates

and the conformity declaration). The hoist can

be delivered on: pallets, crate, closed case,

according to the requirements of the customer

when making the order. For "closed cases"

respect the handling instructions as well as the

indications and symbols marked thereon.

Before handling the packaging, take note of the

weight of the load unit signed on the package

and use proper tools.

If the hoist should not be installed immediately,

note the following points:

The standard packaging is not rainproof" and

is intended for transport by land, and not by

sea, inside covered rooms, without humidity.

The packed and suitable preserved equipment

can be stored indoors for a period of about 5

years, at a temperature between -20° and +70°C

and 80% humidity. Different environmental

conditions require a special package.

Identify the hold points, if any, marked on each

package unit with the corresponding symbol.

Before handling the load unit, visually check

the package, and consequently the goods, for

breaks or damages.

DYNAMIC TEST

mass=

rated capacity x 1.1

STATIC TEST

mass=

•

rated capacity x 1.25

besides the rated capacity of 1000 kg.

•

rated capacity x 1.5

up to rated capacity of 1000 kg.

•

the static test must be carried out

without starting the motor, but only

by applying the load to verify the

hold of the brake (see page 45).

Check the suitability of the power supply line

and the current / voltage values accordingly to

the content of the order confirmation.

Verify that this documentation corresponds to the

hoist to be installed.

Instructions on lifting means and holding points

Handle

with care

Do not

overturn

Protect

from rain

Do not

stack

Manual for installation,

operation and maintenance of

the wire rope hoists XM Series

Summary of Contents for XM SERIES

Page 2: ......

Page 71: ...71 Manual for installation operation and maintenance of the wire rope hoists XM Series NOTE ...

Page 72: ...72 Manual for installation operation and maintenance of the wire rope hoists XM Series NOTE ...

Page 73: ...73 Manual for installation operation and maintenance of the wire rope hoists XM Series NOTE ...

Page 74: ...74 Manual for installation operation and maintenance of the wire rope hoists XM Series NOTE ...

Page 75: ......