65

ELECTRIC WIRE ROPE HOIST

XM SERIES

a

4. OPERATION AND MAINTENANCE INSTRUCTIONS

4.10 ADJUSTMENTS

4.10.1 ADJUSTMENT FO THE CONICAL HOIST

MOTOR BRAKE

This step must be performed with a still hoist and

without load.

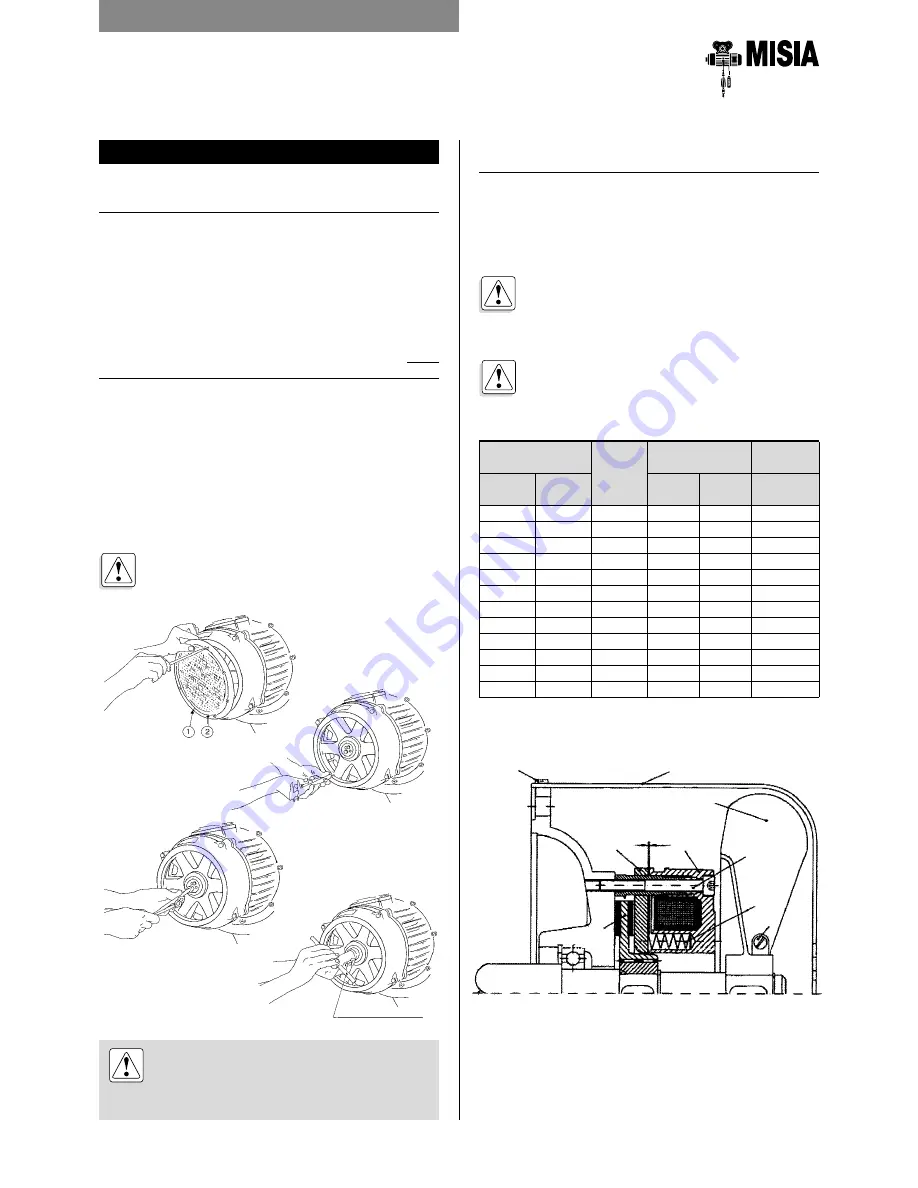

Loosen the screws pos. 1, remove the grid pos. 2,

(Fig. 19); with the brake applied, measure at any point

between the brake fan (Fig. 20) and the surface of the

bell. After this measurement, axially push the fan inside

the motor with the aid of a lever and make another

measurement, recording the difference (Fig. 20). If the

difference is greater than the rated values (0,8/1,2 mm)

proceed as follows:

• loosen the screw (Fig. 21) and then turn the adjusting

ring nut clockwise to take up any axial shifting greater

than the rated value, bearing in mind that one complete

turn of the ring nut corresponds to 2 mm (Fig. 22).

After this take up operation, repeat the measurement

with the brake released (Fig. 20), checking that the

axial shifting is within the rated value, then put back

the screws and the grid in their positions (Fig. 19).

If the measurement indicated is not reached

with the above operation, it is necessary to

replace the fan.

4.10.2 ADJUSTMENT OF BRAKE TYPE "M"

FOR CYLINDRICAL LIFTING MOTOR

- Check the magnetic gap (air gap) "a" and wear of the

brake as for table 16.

The air gap must be restored acting on the screws of

the body brake (position 5), screwing them clockwise

If the thickness of the disk brake is lower than

as shown in table16, it is necessary to replace

it by operating

as described in section 4.9.7.

NB: following the regulation of the magnetic

gap, the braking torque is restored.

ATTENTION! The brakes does not function

properly with an axial shifting over 2.5 mm.

The maximum permissible axial shifting of

the rotor during operation is of 2.5 mm.

Adjustment wrench

Fig. 19

Fig. 20

Fig. 21

Fig. 22

Table 16

Power kW

Type

brake

Air gap

Disk thick-

ness

4

poles

4/12

poles

mm

min.

mm

max

mm

min.

2,5

2,5/0,83

15

0,3

0,9

9,5

4

4/1,3

17

0,3

1,0

11,5

5

5/1,6

17

0,3

1,0

11,5

5,8

5,8/1,9

17

0,3

1,0

11,5

7

7/2,3

20

0,4

1,1

12,5

8

8/2,6

20

0,4

1,1

12,5

12

12/4

23

0,4

1,1

14,5

15

15/5

23

0,4

1,1

14,5

16

16/5,3

26

0,5

1,2

16,5

18

18/6

26

0,5

1,2

16,5

20

20/6,5

26

0,5

1,2

16,5

24

-

26

0,50

1,2

16,5

Summary of Contents for XM SERIES

Page 2: ......

Page 71: ...71 Manual for installation operation and maintenance of the wire rope hoists XM Series NOTE ...

Page 72: ...72 Manual for installation operation and maintenance of the wire rope hoists XM Series NOTE ...

Page 73: ...73 Manual for installation operation and maintenance of the wire rope hoists XM Series NOTE ...

Page 74: ...74 Manual for installation operation and maintenance of the wire rope hoists XM Series NOTE ...

Page 75: ......