2800LX ,UX / 3600UX Brushcutter

23

Original Instructions Version July 12

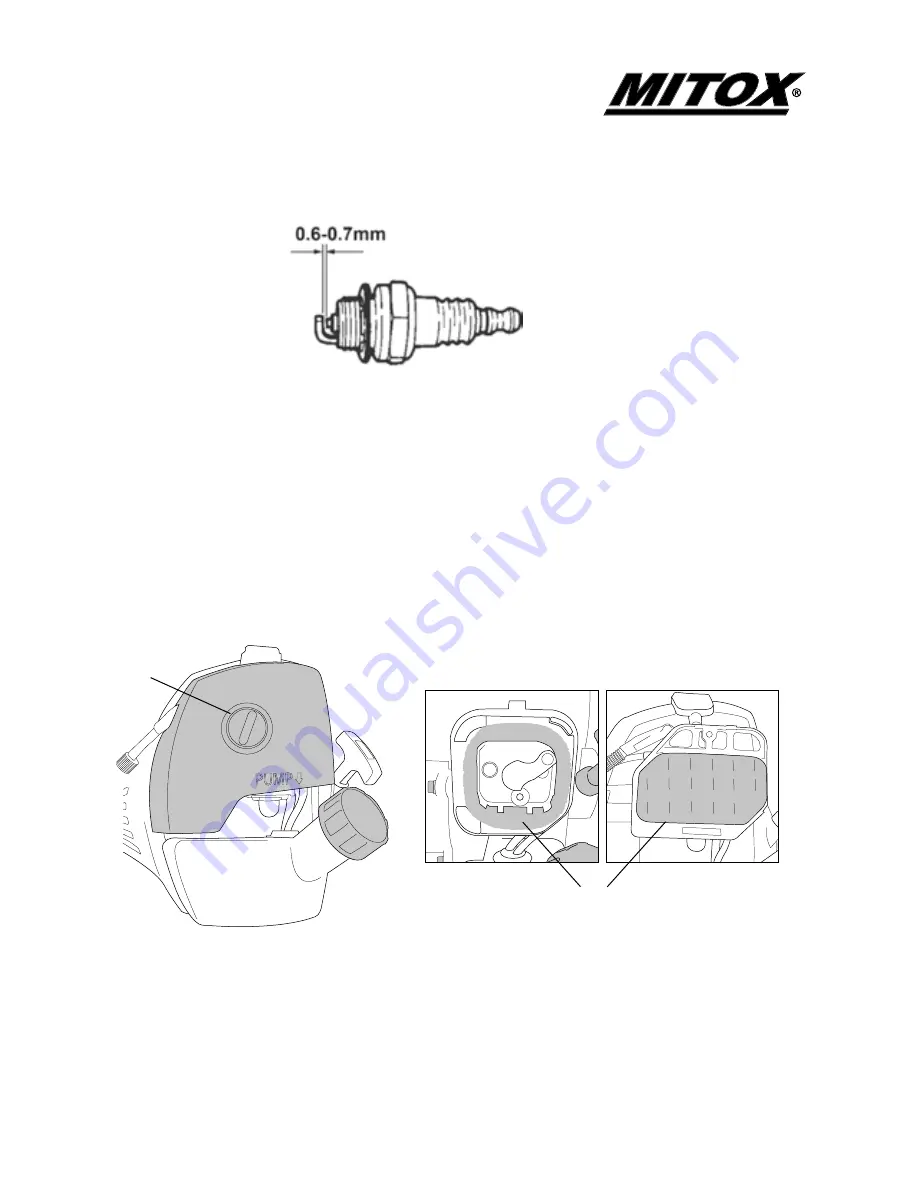

Spark Plug

Poor starting or misfiring is often caused by a fouled or defective spark plug, clean and reset the gap to 0.65

mm, or replace the spark plug with NGK: BPRM7A as necessary.

Air Filter

Before using the brush cutter, check the air filter (a). Being clogged, will reduce the engine performance.

Remove the air filter cover by undoing the cover screw clean the filter element in warm, soapy water, dry

completely before installing. If the element is broken or shrunk, replace with a new one.

(a)

2800

3600

air filter