41 LSH Electric Logsplitter

3

Original Instructions Version August 19

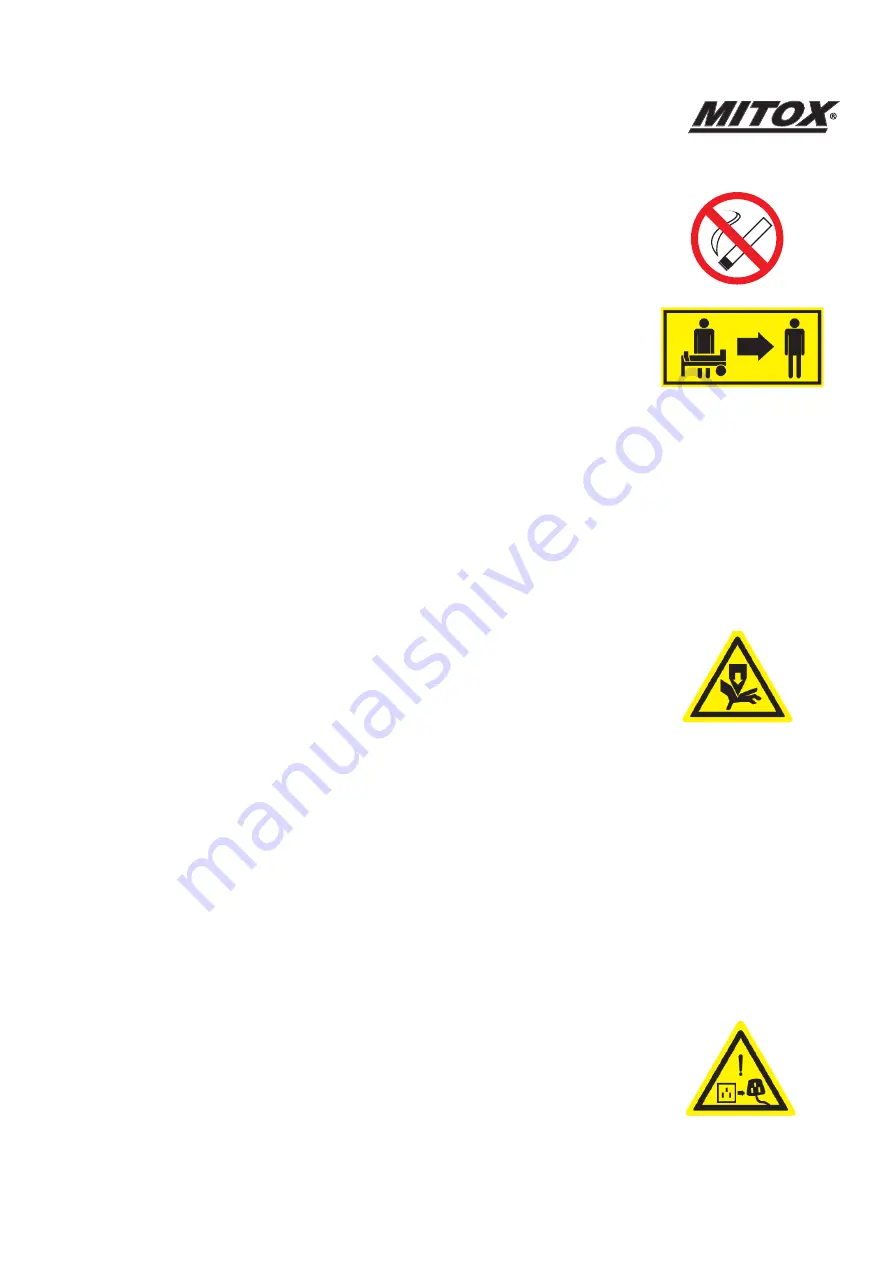

PREVENT FIRES

Do not smoke or have open flames when operating or refilling the log splitter. Never operate

the log splitter near a flame or spark. Oil is flammable and can be ignited.

KEEP BYSTANDERS AWAY

Allow only one person to load and operate the log splitter. Always keep bystanders, including

visitors, children and pets away from the work area, especially when the log splitter is under

operations. Only the operator should stand near the machine and only within the safe

operating area of 5 metres. Never use another person to help you with freeing a jammed log.

No one under the age of 16 should be allowed to operate the log splitter. Any individual under

the age of 18 should have the necessary training and skills to perform the functions properly

and safely and should always be under the supervision of an adult.

INSPECT YOUR LOG

Never attempt to split logs containing nails, wire or debris. Always make sure that both ends

of the log you are splitting are cut as square as possible. This will prevent the log from sliding

out of position while under pressure. Branches must be cut off flush with the trunk.

DON’T OVERREACH

Keep a proper footing and balance at all times. Never stand on the log splitter. Serious injury

could occur if the tool is tipped or if the cutting tool is unintentionally contacted. Do not store

anything above or near the log splitter where anyone might stand on the tool to reach it.

AVOID INJURY FROM UNEXPECTED ACCIDENT

Do not straddle or reach across the splitting area when operating the log splitter. Never pile

logs to be split in a manner that will cause you to reach across the log splitter. Only use your

hands to operate the control levers. Never use your foot, knee, a rope, or any other extension

device. Always pay full attention to the movement of the wedge ram. Never attempt to load

your log splitter while the ram is in motion. Keep hands out of the way of all moving parts.

Never try to split two logs. One of them may fly up and hit you.

PROTECT YOUR HANDS

When the ram of the log splitter is in the return mode, keep your hands off the machine – the

log splitter is designed to automatically stop when the cylinder is fully retracted. Keep your

hands away from splits and cracks which open in the log. They may close suddenly and crush

or injure your hands.

INCORRECT USE

Do not use the log splitter for a purpose for which it was not intended. Do not, under any

circumstances, alter your log splitter. This equipment was designed and engineered to be

used in accordance with the operating instructions. Altering the equipment, or using the

equipment in such a way as to circumvent its design capabilities and capacities, could result

in serious or fatal injury and will void the warranty. Never try to split logs larger than those

indicated in the specifications table. This could be dangerous and may damage the machine.

NEVER LEAVE THE LOG SPLITTER RUNNING UNATTENDED

Don’t leave the tool until it has come to a complete stop.

DISCONNECT POWER

Unplug the log splitter when not in use, before making adjustments, changing parts, cleaning

or working on the log splitter. Consult your local Mitox dealer before servicing.