LS700BS 7 Ton Petrol Logsplitter

13

Original Instructions Version April 13

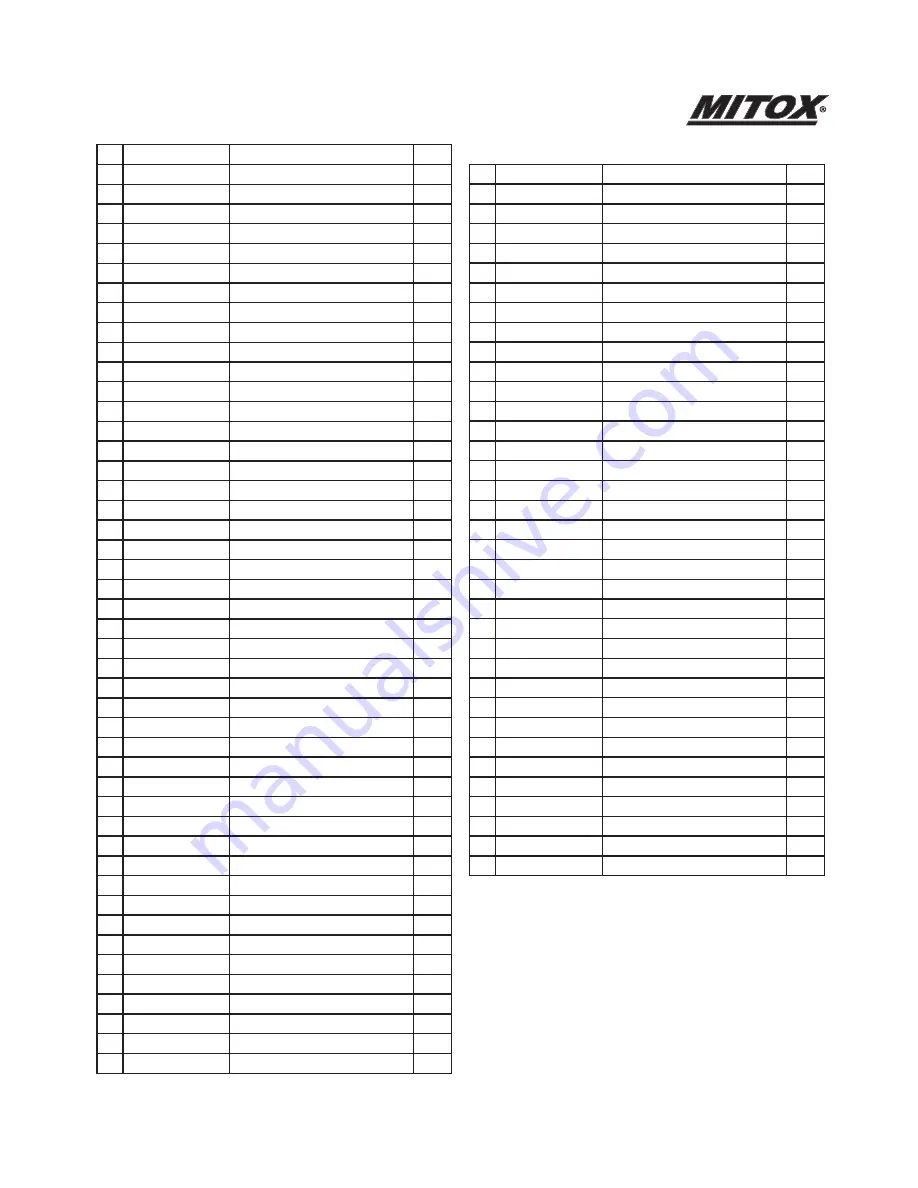

ID

PART No

DESCRIPTION

QTY

1

MICCQ01

UPRIGHT TUBE WELDMENT - B&S

1

2

MICCQ62

PUMP GUARD

1

3

MIGG/T93-1987

SPRING WASHER M6

1

4

MIGB/T822-2000

SCREW M6X12

1

5

MIGB3452.1-92

O-RING 23.6X3.55G

1

6

MICCA.00.101

CAP

1

7

MIGB/T95-1985

WASHER M10

26

8

MICCA.00.109

LOCK-OUT LEVER

6

9

MIGB/T5781-2000

BOLT M10X35

8

10

MICCA.00.107

R/H CLAMPING FORK

1

11

MICCQ03.1.1

R/H GUARD ASSY

1

12

MICCA.00.125

KNOB M8X20

2

13

MICBC.40.113

FORK

2

14

MICCA.00.105

CONTROL LEVER SHAFT

2

15

MICCB.05.002

WORK TABLE 2

1

16

MICCA.00.122

PLASTIC INSERT (4)

1

17

MICCA.00.120

PLASTIC INSERT (2)

1

18

MICCA.00.119

PLASTIC INSERT (1)

1

19

MICCA.00.121

PLASTIC INSERT (3)

1

20

MICCA.00.106

L/H CLAMPING FORK

1

21

MICCQ04.1.1

L/H GUARD ASSY

1

22

MIGB/T822-2000

SCREW M6X10

6

23

MIGB/T95-1985

WASHER M6

6

24

MIGB/T802

LOCKNUT M10

6

25

MICFA.00.018

WHEEL A

2

26

MIGB/T894.1-1986

CIRCLIP 16

2

27

MIGB/T5786-2000

BOLT M16X15

1

28

MIJB982-77

WASHER GROUPWARE 16

1

29

MICCA.00.123

SLIDING PLATE

4

30

MICCA.00.126

KNOB

1

31

MICCA.00.129

WEDGE BRACKET ROUND COVER

2

32

MICCA.00.124

ROUND COVER

1

33

MICCA.00.118

SQUARE COVER

1

34

MILS700BS-34

NUT M20

3

35

MICCQ59

HIGH PRESSURE OIL HOSE 24

1

36

MIGB/T93-1987

SPRING WASHER M8

6

37

MILS700BS-37

LOCKNUT M6

1

38

MIGB/T5785-2000

BOLT M8X25

2

39

MIGB/T894.1-1986

CIRCLIP 22

4

40

MICCA.00.102

LOCK SHAFT

1

41

MICCQ02

CCQ CYLINDER

1

42

MIGB/T5781-2000

HEX BOLT

2

43

MICCA.02.104

LEVER HANDLE

2

44

MILS700BS-44

LOCKNUT M8

2

45

MICCD.00.103

PIN D

1

46

MICCA.02.103

OPERATE HANDLE

2

47

MIGB/T41-2000

THIN NUT

6

48

MIGB/T95-1987

WASHER M8

14

49

MICCA.09.001

CONTROL LINK PLATE

1

50

MIGB/T802

NUT

1

51

MICCA.07.109(0)

DRAW ROD LOCK COVER

1

52

MILS700BS-52

SUPPORTING RING

1

53

MICCA.00.108

DRAW ROD

1

54

MICCA.09.103(0)

DRAW SLEEVE NUT

1

55

MIGB/T6172.1

THIN NUT M16

1

56

MICCA.08.001

DRAW SLEEVE

1

57

MILS700BS-57

HOSE CLAMP 22-28

4

58

MIGB/T5780-2000

BOLT M6X30

1

59

MICCA.16.001

CA VALVE

1

60

MICCB.07.001

WEDGE BRACKET WELDMENT B

1

61

MICCQ43

T-CONNECTOR - TAPE

1

62

MIJ982-1977

WASHER GROUPWARE 20

12

63

MICCQ57

VALVE TUBE NOZZLE

1

64

MICCQ60

HIGH PRESSURE OIL HOSE 24

1

65

MICCQ34

VALVE INJECTION NOZZLE

1

66

MILS700BS-66

OIL RETURN PIPE

1

67

MICCQ61

HIGH PRESSURE OIL HOSE

1

68

MICCQ29

NOZZLE 9/16-18-UNF-2BXM20X1.5

1

69

MICDB2-F203.4ALP

GEAR PUMP

1

70

MICCQ46.4

ORIENTATION RING

1

71

MICCQ46.3

JOINING

1

72

MII/C6.5HP

ENGINE (B&S)

1

73

MIGB/T5785-2000

BOLT M8X35

4

74

MICCQ68

RUBBER WASHER (UR)

1

75

MIGB/T5786-2000

BOLT M8X30

4

76

MICL090 12.7-19

REV JOINT - CL090 12.7-20

1

77

MILS700BS-77

GRUB SCREW

2

78

MILS700BS-78

INTAKE HOSE

1

79

MICCQ51

TIE-IN 20

1

80

MICCQ32

NOZZLE 3/4-16-UNF-2BXM20X1.5

1

81

MI700-79

CROSSCUT WEDGE - VERTICAL

1

82

MI700-80

WEDGE RETAINING BOLT

1