Summary of Contents for 88-DCDD

Page 1: ...2450 A amo SE Albuquerque NM 87t06 ...

Page 6: ...D I S K S Y S T E M B L O C K D I A G R A M 10 NEXT DISK DRIVE ...

Page 7: ...r ...

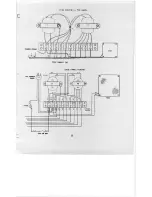

Page 9: ...DISK CONTROLLER BLOCK DIAGRAM S H E E T 2 I N T E R N A L C O N N E C T I O N S 8 0 A R 0 I ...

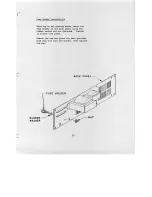

Page 17: ... k c c n t r o e r a s s e m b l y p r o c e d u r e ...

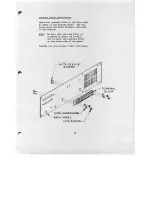

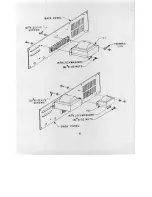

Page 26: ...disk drive assembly procedure ...

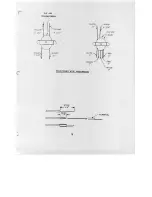

Page 31: ...cut off YELLOW GREEN TRANSFORMER WIRE PREPARATION STRIP r i BEND TERMINAL 5 ...

Page 32: ...16 ...

Page 41: ...o O O o o o o o f o y o O O O O O O f O o o 25 ...

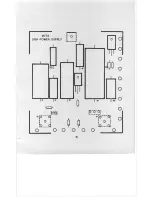

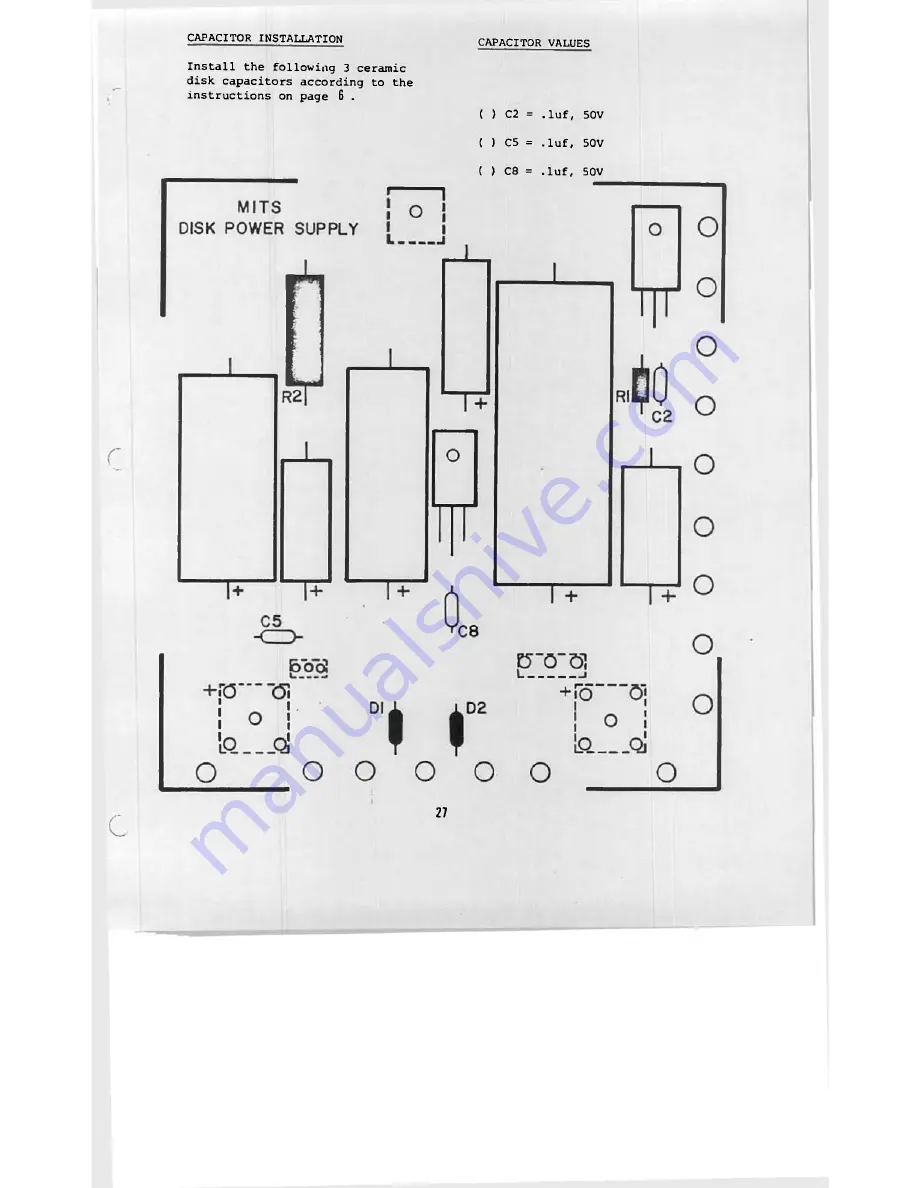

Page 44: ...r M TS o D SK POWER SUPPLY R 2 T C5 000 O o C 8 C C3 t D O O O O O 29 o ...

Page 62: ...37 PIN MALE CONNECTOR PIN 12 NOT USED 49 ...

Page 63: ...o o o o o 50 ...

Page 64: ...37 PIN FEMALE CONNECTOR PIN 12 NOT USEO 51 ...

Page 69: ......

Page 73: ...c c 61 ...

Page 76: ......

Page 78: ...67 ...

Page 80: ...ALTAIR FLOPPY DISK DRIVE POWER SUPPLY WIRING DIAGRAM u ...

Page 87: ......

Page 92: ... 1 is ...

Page 95: ...o o o o o o o o o o o o o o o o o o o o i r 0 0 O a E D 87 ...

Page 97: ...K 1 E 0 E L J EI 1 m n Ln O a E D 89 ...

Page 99: ...t6 C O t o E I 3 E 3 d n cn ...

Page 101: ...E6 1 o Y L E 3 C 3 L 3 r r n J ...

Page 103: ...S t B 3 JJ o a E 3 a a i a a a a c i 4 W R 8 C o o o o o o o o o o o o o o o o o o o o ...

Page 107: ...J I I I i L a J I I I I I i J L o O O a J L J I I L L3 99 ...

Page 113: ...J I L J J J BtttO S J I I i I i i L I I L ...

Page 115: ... J L 3 5 5 if i i i E n m o I I L E I L 9 2 3 p 8 J LSJ L OS 07 ...

Page 117: ...c L E T 1 E J E U E Z 3 C D i t t 1 5 1 1 1 I I 1 tBt M P I i i t i 1 t i n 3 i O S 09 6 ...

Page 119: ......

Page 121: ...DISK CONTROLLER CABLE 17 PIN CONNECTOR STRIP 1 8 INCH TIN RIBBON CABLE SHEATH INCH 13 ...

Page 131: ...READ URITE OUTPUT PROGRAM t T O MO 0 7 4 i M S 1 wtm t h CM 4 D C t l C t m t l In L ...

Page 132: ......

Page 133: ...STEPPING PROGRAM ...

Page 137: ... J Tt 0 TIP 145 HEATSINK ON CHASSIS DISK DRIVE POWER S U P P L Y ...

Page 138: ...Disc PC Card ...

Page 139: ......

Page 140: ...e ...

Page 143: ...Disc 2 1 ...

Page 144: ...CO B B Disc 2 2 ...

Page 147: ...DTSK CONTROLLER BOARD 1 SHEET 2 OF 3 ...

Page 149: ...DISK CONTROLLER BOARD 2 SHEET 1 OF 3 WRITE DATA S DISK ENABLE CIRCUITS ...

Page 152: ...p s n a 7 PCEA FLEXILE DISK DPivE ECTRO iCS EASic A j r ...

Page 153: ...JimH iim W W a ...

Page 154: ......

Page 156: ...4 3 2 1 SM S J 3 3 svy F T WZtTE RUSY KETUEM b 6 0 0 1 9 0 D A J f at 5 ...

Page 158: ...7 t 32 oa o 5 j a _ 3 _ 3_ cz ...

Page 159: ...rc m c C C n rn r U 5 O 13 rn m r ...

Page 160: ...o X US m rs L t o u 5 O c o 3 3 o u t M 71 3 5 ...

Page 161: ...J OR Vf ...

Page 163: ...D 6 0 0 1 9 0 D 3 ot j E ...

Page 164: ...7 4 02 1 D c 0 0 l 9 0 r ...

Page 165: ......

Page 166: ...4 3 TTAC K 33EO CE D Ss rE xseoo 1 SH05 f I 5 K 4 3 ...

Page 167: ......