38

NP180/160 Series Setup Manual

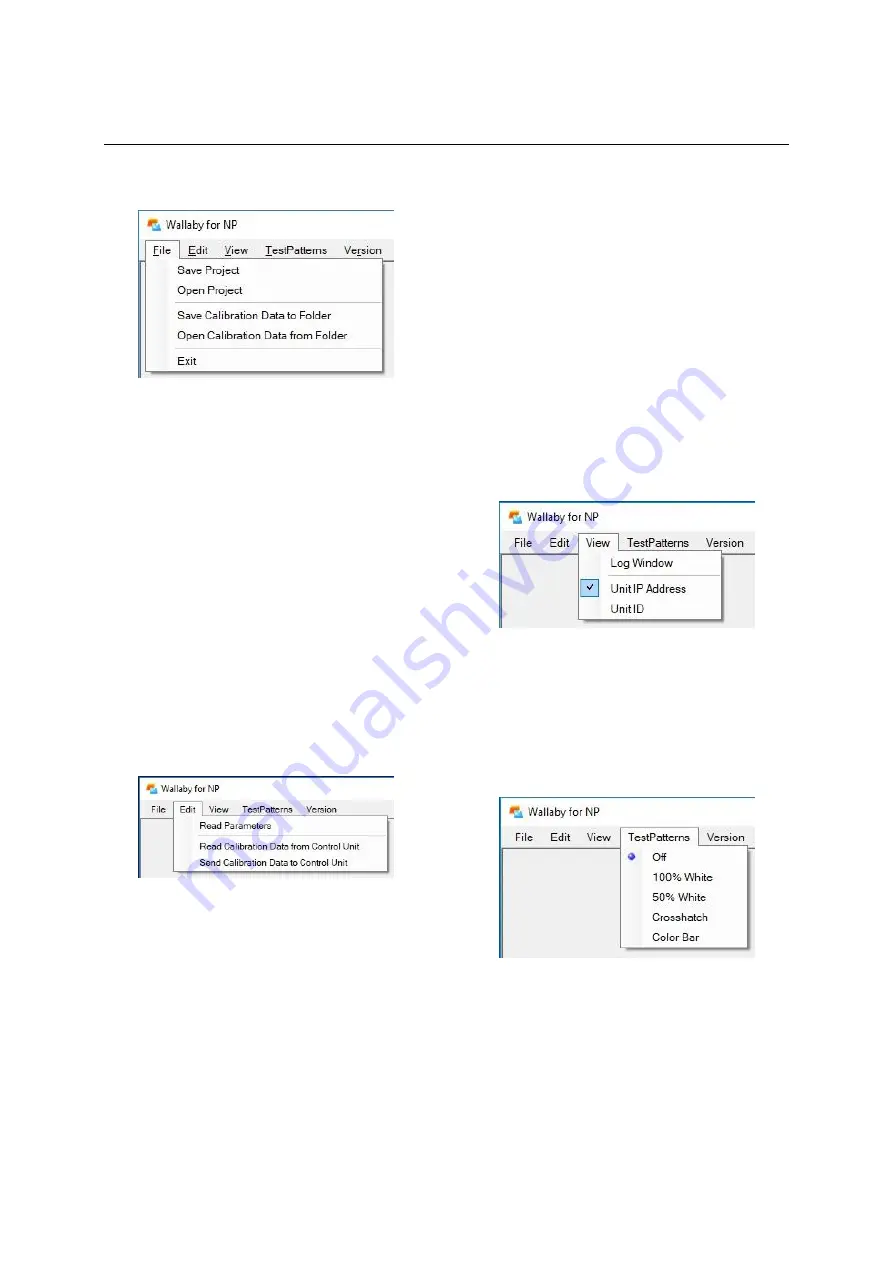

Wallaby menu bar

The menu bar in Wallaby has the following functions.

File

Save Project

Saves the configuration information (p. 23) that has

been set in the Configuration tab into the computer.

Open Project

Opens the configuration information saved with the

above “Save Project” menu on Wallaby.

Save Calibration Data to Folder

Saves all the calibrated color data retained in

Wallaby into the computer.

The “Save in Control Unit” menu in the

“Maintenance” tab (p. 26) saves the displaying

color data on the LED units into the control unit(s).

Open Calibration Data from Folder

Opens the color data saved in the computer with

the above “Save Calibration Data to folder” menu

on Wallaby.

Edit

Read parameters

Reads out the data in the selected control unit to

update the data in Wallaby. This operation is

normally no need. Wallaby automatically updates

necessary data whenever it communicates with the

control units.

Read Calibration Data from Control

unit

Reads out the color data in all the control units to

Wallaby.

The “Read from Control Unit” menu in the

“Maintenance” tab (p. 26) reads the data only

from the selected control unit(s).

Send Calibration Data to Control unit

Saves the color data in Wallaby into all the control

units.

The “Save in Control Unit” menu in the

“Maintenance” tab (p. 26) saves in only the

selected control unit(s).

View

Log Window

Displays the communication log window.

Unit IP Address / Unit ID

Displays the IP address and the unit ID of each

control unit on the panel area in Wallaby.

Test Patterns

Displays an internal test pattern on the selected

control unit area.

Summary of Contents for 12NP180 Series

Page 50: ......