6

NP180/160 Series Setup Manual

2.

Preparation

Necessary network cables

Prepare the following commercially-available network cables. The length and quantity vary depending on the

system configurations.

For video

transmission

control unit to LED units

Up to 10 m:

Up to 15 m:

Up to 20 m:

CAT 7 network cables

CAT 7 solid conductor or CAT 7A network cables

Mitsubishi confirmed network cables

between LED units

Recommended:

0.7 m or longer

CAT 7 network cables

For controlling

(160 Series)

control unit to power unit

Up to 60 m*:

CAT 5 or higher network cables

between power units

Recommended:

0.2 m or longer

*: It is the total length between the control unit and the last cascaded power unit.

Necessary tools

Hex key

5 mm

Philips screwdriver

#2

Wrench

13 mm (for nuts that fix the adjustment screws)

Digital level

Recommended: accuracy: 0.05° or finer, length: 600 mm or longer

Spacers

(for edge protection at

LED unit mounting)

S-160SP (p. 3): a set of 0.075, 0.100, 0.125, 0.188 mm thickness spacers

Recommended thickness when using store-bought spacers: 0.07 mm to 0.19 mm

Thin spacers

(for LED unit height alignment)

Recommended thickness: 20

μ

m to 50

μ

m, tapes or shim rings etc. (p. 17)

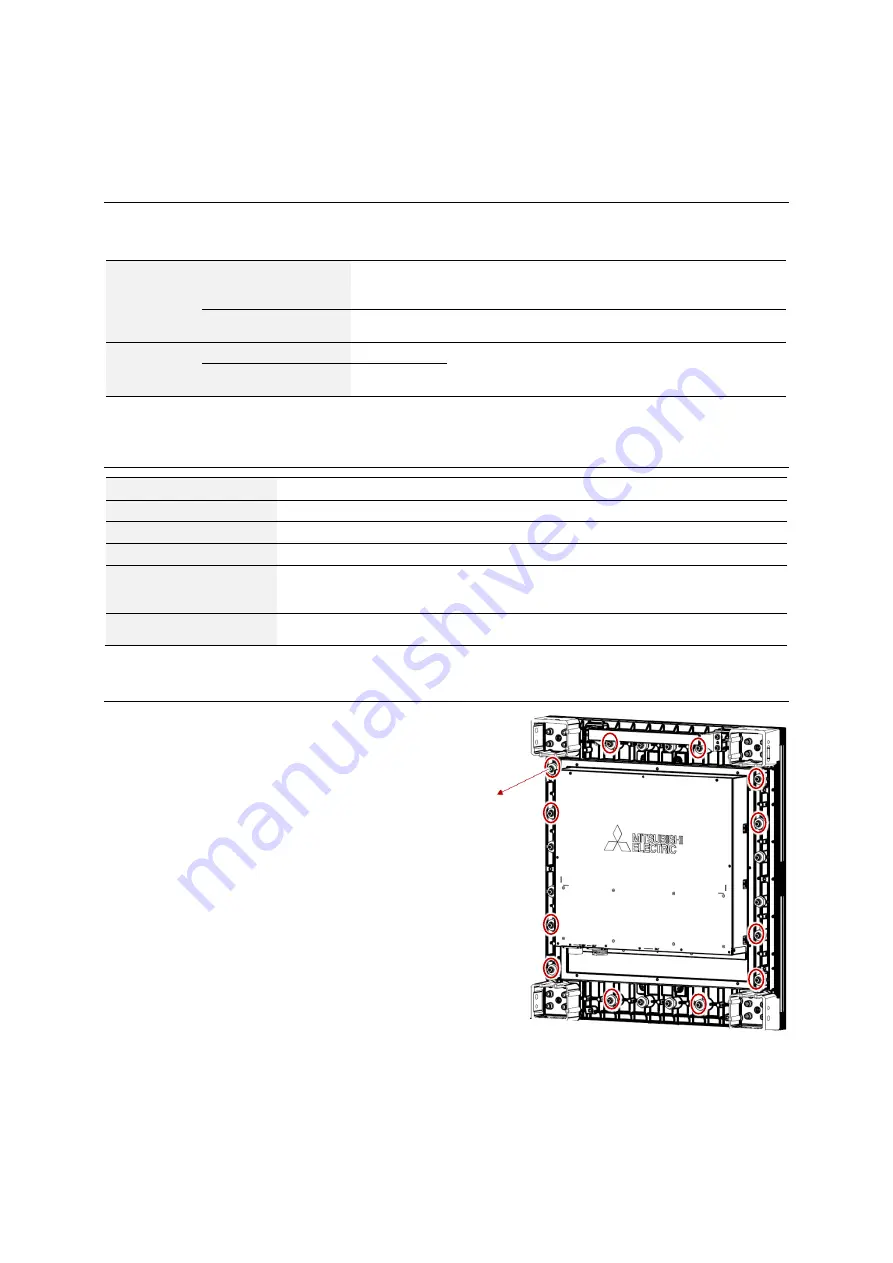

Lock screw releasing (front models)

Before installation, remove 12 lock screws for transportation

with a screw driver from each LED unit of the front

maintenance models.

Without releasing, you may not able to remove an LED

module (p. 39) if the LED wall doesn’t have enough back

space.

The rear maintenance models don’t have such lock screws.

Summary of Contents for 12NP180 Series

Page 50: ......