11

GB

D

F

I

NL

E

SW

P

9.1. Caution

1

Follow ordinance of your governmental organization for technical standard re-

lated to electrical equipment, wiring regulations and guidance of each electric

power company.

2

Set up the outdoor unit so that the wiring for the remote controller and the M-

NET (MELANS) wiring do not produce electrical interference with the power

supply cable. (Do not route them together in the same conduit.)

3

Be sure to provide designated grounding work to outdoor unit.

4

Give some allowance to wiring for electrical part box of indoor and outdoor

units, because the box is sometimes removed at the time of service work.

5

In the indoor/outdoor connection wiring, the power and signals wiring are con-

tained in the same multiconductor cable. Since the cable is polarized, be sure

the connection is according to the terminal number.

6

For detailed information about the power supply cable, see the manual sup-

plied with the indoor unit.

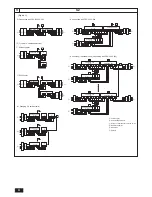

9.2. Wiring and fitting capacities

(1) PUH-P200, 250

Main power supply wire thickness, switch capacities and system impedance.

PUH-P200

PUH-P250

Power supply thickness *1

mm

2

4 or more

6 or more

Overcurrent protector *2

A

32

40

Earth leakage breaker ELB

A

(with over-load protection)

mm

2

Cable or wire of 0.3 ~ 1.25 mm

2

(max. DC 12 V)

mm

2

1.5 or more

mm

2

0.5 or more

mm

2

4 or more

6 or more

Ω

0.07

0.05

Heat

insulation

material A

Outer

covering B

9. Wiring

Electr

ical w

o

rk

Main wire

Outdoor

Thickness of wires for remote control-

ler and indoor unit *1

Thickness of wire between indoor and

outdoor unit *5

Thickness of wire between outdoor and out-

door unit (connecting with PEH-P400, 500)

Ground wire thickness

Max. Permissive System impedance *6

NV is a product name of MITSUBISHI.

Notes:

*1: “Power supply thickness” indicates the thinnest allowable metal wire.

*2: “Overcurrent protector” indications are for when class B fuse are used.

*3: Power supply cords and indoor unit/outdoor unit connecting cords shall

not be lighter than polychloroprene sheathed flexible cord. (Design 245

IEC 57).

*4: A switch with at least 3 mm contact separation in each pole shall be pro-

vided by the Air conditioner installation.

*5: The connection wiring between the outdoor and indoor units can be ex-

tended up to a maximum of 80 m.

If 4 mm

2

used and S3 separated, Max. 50 m.

If 6 mm

2

used and S3 separated, Max. 80 m.

*6: This device is intended for the connection to a power supply system with

a maximum permissible system impedance ZMAX of 0.07

Ω

:PUH-P200,

0.05

Ω

:PUH-P250 at the interface point (power service box) of the user’s

supply.

The user has to ensure that this device is connected only to a power

supply system which fulfills the requirement above.

If necessary, the user can the ask the public power supply company for

the system impedance at the interface point.

Warning:

Always use the designated cable for wiring, and connect it correctly. Secure

it so that the cable applies no external pressure to the terminal connection. If

the connection is faulty or the cable is not fully secured, overheating or fire

could result.

Caution:

•

Depending on the location of the unit, a current leakage breaker may be

required. If a current leakage breaker is not installed, electric shock could

result.

•

Do not use breakers or fuses with a capacity different from the correct

one. If large-capacity fuses, wire, or copper wiring are used, accident or

fire may result.

Table above is an example. The selection of other capacities should be deter-

mined in accordance with the relevant standards.

Types of cable/cord

•

Vinyl cab tire round cord: VCTF

•

Vinyl insulating vinyl sheath cable round type: VVR

•

Vinyl cab tire flat cord: VCTFK

•

Vinyl insulating vinyl sheath cable flat type: VVF

•

Vinyl insulating vinyl sheath cable for control: CVV

•

600 V vinyl cab tire cable: VCT

•

Vinyl insulating vinyl sheath cable for control: CVS

Warning:

Be sure to use specified cables and connect them firmly so that no external

wiring force is exerted on terminal connections. Loose connections may cause

heat or fire.

Caution:

•

Some installation sites may required installation of an earth leakage

breaker. Failure to install it may result in an electric shock.

•

Always use an earth leakage breaker and fuse with the specified capac-

ity. Use of a fuse with a capacity larger than that specified, or use of a

piece of wire or copper wire may cause breakdown or fire.

Example

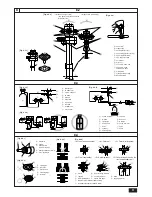

[Fig. 9.2.1] (P.4)

(1) Connecting with PEH-RP200, 250

(2) Free multi-component system

1

Without heater

2

With heater

(3) Grouping (16 outdoor units)

(4) Connecting with PEH-P400, 500

(5) Grouping (16 outdoor units) [Connecting with PEH-P400, 500]

1

single

2

twin

A

Power supply

B

Earth leakage breaker

C

Wiring circuit breaker or isolating switch

D

Remote controller

E

Indoor unit

F

Address

NV100-SW

30

100mA 0.1s or less

NV100-SW

40

100mA 0.1s or less

Glass fiber + Steel wire

Ad Heat - resistant polyethylene foam + Adhesive tape

Indoor

Vinyl tape

Floor exposed

Water-proof hemp cloth + Bronze asphalt

Outdoor

Water-proof hemp cloth + Zinc plate + Oily

paint

Note:

•

When using polyethylene cover as covering material, asphalt roofing

shall not be required.

•

No heat insulation must be provided for electric wires.

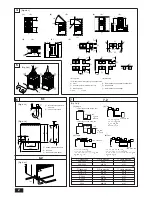

[Fig. 8.4.2] (P.3)

A

Liquid pipe

B

Gas pipe

C

Electric wire

D

Finishing tape

E

Insulater

[Fig. 8.4.3] (P.3)

Penetrations

[Fig. 8.4.4] (P.3)

<A> Inner wall (concealed)

<B> Outer wall

<C> Outer wall (exposed)

<D> Floor (fireproofing)

<E> Roof pipe shaft

<F> Penetrating portion on fire limit and boundary wall

A

Sleeve

B

Heat insulating material

C

Lagging

D

Caulking material

E

Band

F

Waterproofing laye

G

Sleeve with edge

H

Lagging material

I

Mortar or other incombustible caulking

J

Incombustible heat insulation material

When filling a gap with mortar, cover the penetration part with steel plate so that

the insulation material will not be caved in. For this part, use incombustible materi-

als for both insulation and covering. (Vinyl covering should not be used.)