App - 2 App - 2

MELSEC-A

APPENDIX

App.

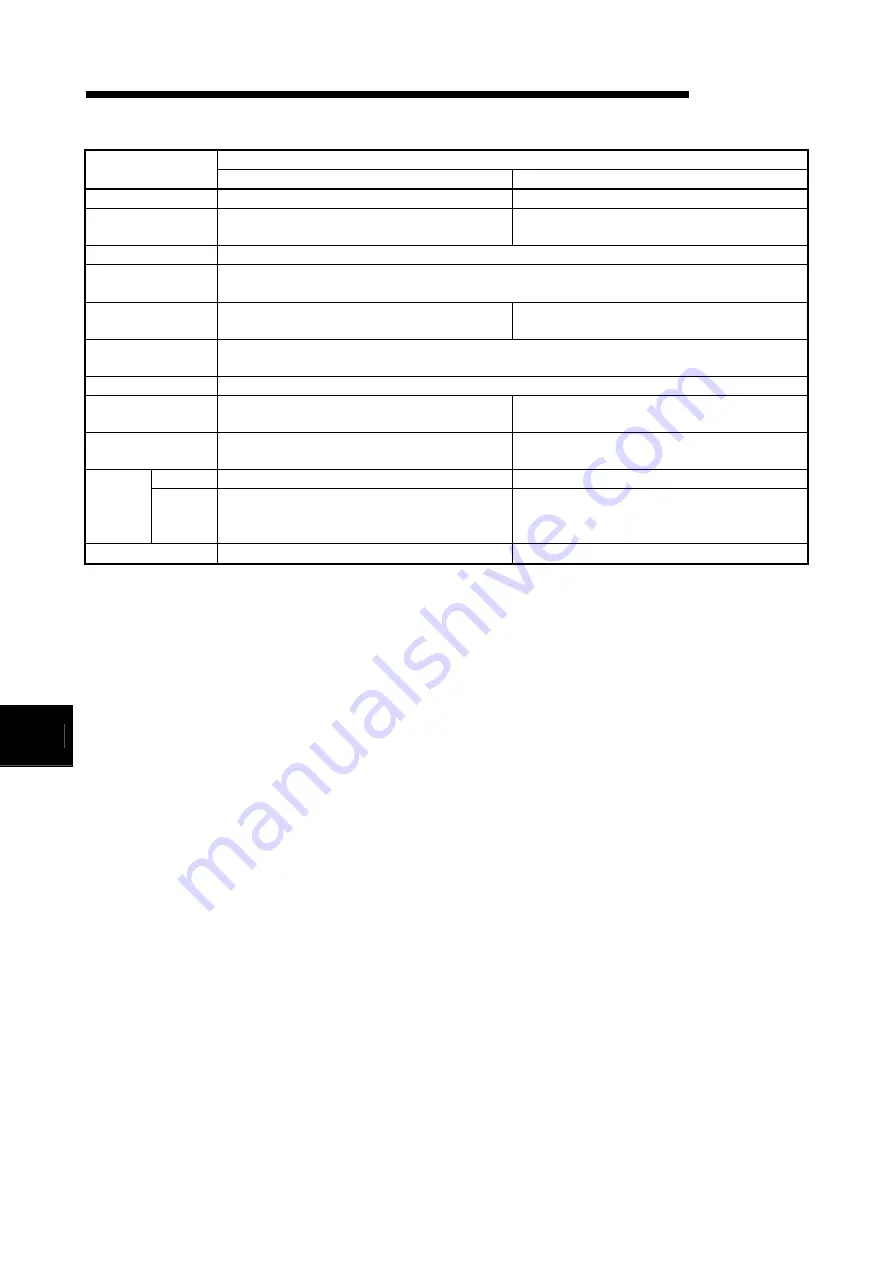

Specification

Item

A1S66ADA A1S63ADA

Simple loop control

Not available

Available

Analog value read/write

method

I/O signal method

Buffer memory method

Overall accuracy

Within

±

1 % (accuracy relative to the maximum value)

Insulation method

Between I/O terminal and PLC power supply··········Photocoupler insulation

Between channels····················································No insulation

Number of I/O occupied

points

64 points

32 points

Connected terminal

base

20 points terminal block (M3.5

×

7 screw)

Applicable wire size

0.75 to 1.25 mm

2

Applicable solderless

terminal

R1.25-3 1.25-YS3 2-3.5 2-YS3A

V1.25-M3 V1.25-YS3A V2-S3 V2-YS3A

1.25-3.5 1.25-YS3A 2-3.5 2-YS3A

V1.25-M3 V1.25-YS3A V2-S3 V2-YS3A

5 V DC internal current

consumption

0.21 A

0.8 A

Voltage

21.6 to 26.4 V DC

⎯

External

power

supply

Current

consump-

tion

0.16 A

⎯

Weight

0.33 kg

0.30 kg

Summary of Contents for A1S66ADA

Page 2: ......

Page 13: ...2 2 2 2 MELSEC A 2 SYSTEM CONFIGURATION 2 MEMO ...

Page 44: ...6 2 6 2 MELSEC A 6 TROUBLESHOOTING 6 MEMO ...

Page 51: ......