α

2 Simple Application Controllers

Function Blocks 6

6 - 57

Note:

Other PID systems may calculate proportional control based on the magnitude of the current

deflection only.

Table 6.27: Units for K

P

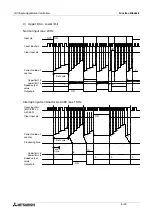

Figure 6.22a. Characteristic response for different K

P

parameters

Integration Time, T

I

.

A common problem with P-control is that it tends to stabilize the PV at a

value not equal to the SV (this is called an offset error). With PI-control, a temporal integration

factor is added to deal with this problem. The idea behind PI-control is to ramp up the effect of

P-control, if an offset error persists over time. The T

I

parameter can be set manually or

automatically with the Auto-tuning function. The default value for T

I

is 40 (4 seconds) but can

be set to any value within the range of 1 to 32767 (in 100ms units). When a small value for T

I

is

set, the PV will reach the SV within a relatively short amount of time with greater searching

(e.g. more overshoot and more undershoot) for the SV.

Note:

Setting zero for this variable disables the integration effect.

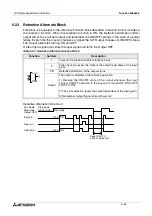

Figure 6.22b. Characteristic response for different T

I

parameters

Units

Type of Word data

Default Value

Range

0.1%

· Analog input

· Function Block word output

· Temperature input using the

Celsius scale.

7.5%

0.1% to 3276.7%

0.01%

· Temperature input using the

Fahrenheit scale

0.75%

0.01% to 327.67%

Time

Set value (SV)

Process value (PV)

offset error

K

P3

> K

P2

> K

P1

(Proportional gain)

K

P3

K

P2

K

P1

PV

Time

Set value

(SV)

Process value in P-action

T

I3

0 < T

I3

< T

I2

< T

I1

Process value in PI action

T

I2

T

I1

PV