6. Mounting the Branch Box

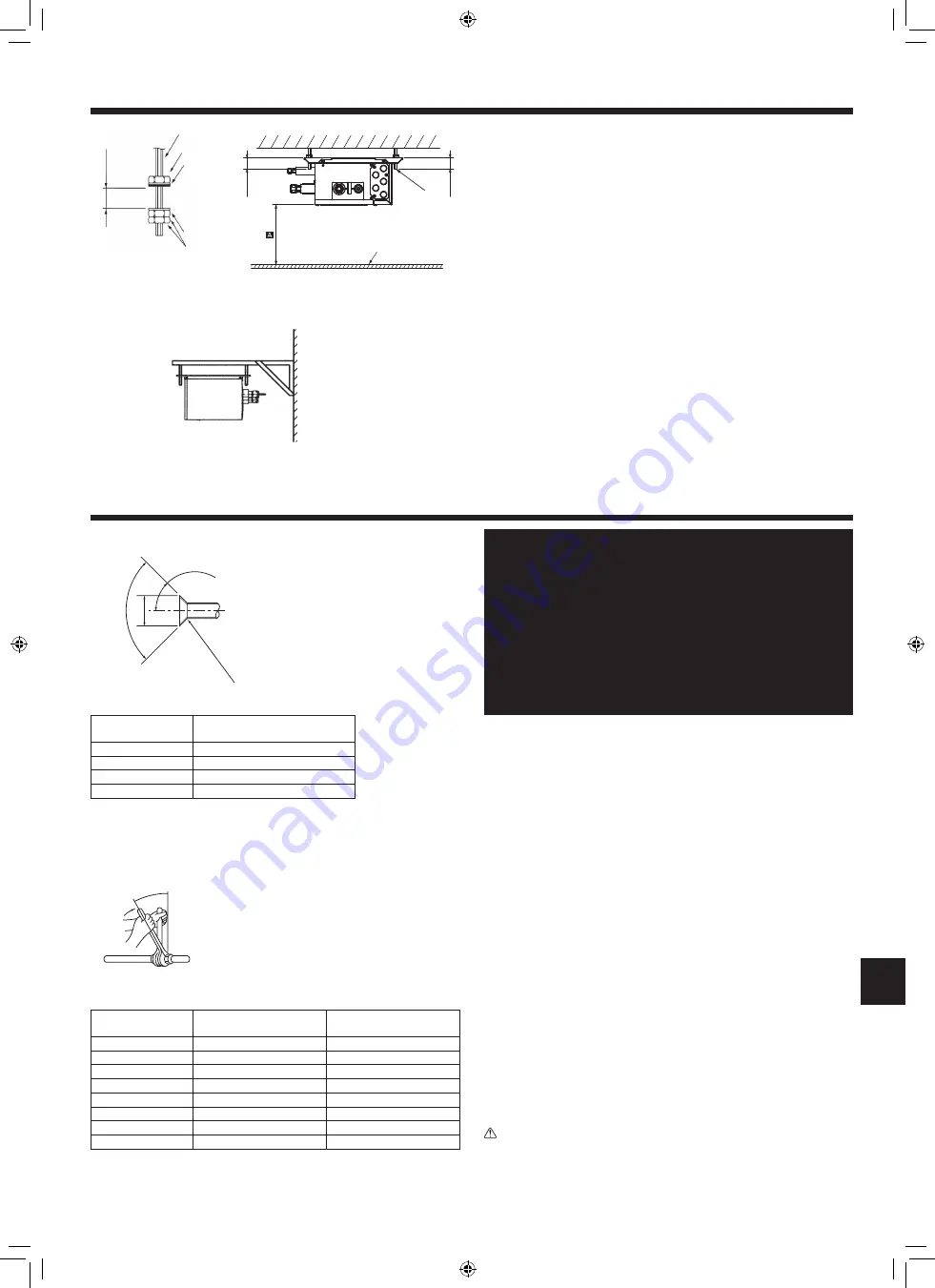

(1) Install the suspension bolts (procure locally) at the specified pitch (Fig. 4-2, 4-3).

(2) Fit the washers (

1

,

2

) and nuts (procure locally) to the suspension bolts.

(Fig. 6-1)

(3) Hang the unit on the suspension bolts.

(4) Fully tighten the nuts (check ceiling height).

(5) Use a level to adjust the branch box to the horizontal.

A

When unit is hung and nuts tightened

B

Suspension bolt

C

Nut (procure locally)

D

Washer (with cushion)

1

E

Ensure that cushion faces downwards

F

Washer (without cushion)

2

G

Nut (procure locally)

H

Ceiling board

7. Installing refrigerant piping

B

H

C

F

A

G

D

(

E

)

B

Table 1

(mm (inch))

Copper pipe O.D.

Flare dimensions

øA dimensions

ø6.35 (1/4)

8.7-9.1 (11/32-23/64)

ø9.52 (3/8)

12.8-13.2 (1/2-33/64)

ø12.7 (1/2)

16.2-16.6 (41/64-21/32)

ø15.88 (5/8)

19.3-19.7 (49/64-25/32)

(inch)

► Connect the liquid and gas pipes of each indoor unit to the same end

connection numbers as indicated on the indoor unit flare connection

section of each Branch Box. If connected to wrong end connection

numbers, it doesn’t work normally.

► When connecting indoor units, make sure to connect refrigerant pipes

and connection wires to the appropriate connection ports marked with

matching alphabets. (Ex. A, B, C, D, E) If connected to wrong end con

-

nection numbers, it doesn't work normally.

Note:

Be sure to mark all the local refrigerant piping (liquid pipes, gas pipes, etc.)

for each indoor unit designating clearly which room it belongs in. (Ex. A, B,

C, D, E)

► List indoor unit model names in the name plate of Branch Box (for iden

-

tification purposes).

• Conduct sufficient anti-condensation and insulation work to prevent water drip

-

ping from the refrigerant piping. (liquid pipe/gas pipe)

• Increase insulation depending on the environment where the refrigerant piping is

installed, or condensation may occur on the surface of the insulation material.

(Insulation material Heat-resistant temperature: 120 °C [248 °F], Thickness:

15 mm [19/32 inch] or more)

* When the refrigerant piping is used in locations subject to high temperature

and humidity such as in the attic, further addition of insulation may be re-

quired.

• Insulate the liquid and gas pipes of the branch box by attaching the heat-resis-

tant polyethylene foam tightly around them. (Fig. 7-4)

Otherwise, a burn during pipe connection work or water leakage due to con-

densation on pipes may result. If connected to wrong end connection numbers,

it doesn't work normally.

► When using commercially available refrigerant piping, ensure that both

liquid and gas piping are wrapped with commercially available thermal

insulation materials (insulation materials at least 1/2 inch (12 mm) thick

and able to withstand temperatures in excess of 100ºC [212°F]).

► Refer to the installation manual of the outdoor unit when creating a

vacuum and opening or closing valves.

7.1. Piping connection procedure

(1) Remove the flared nuts and caps from the branch box.

(2) Flare the end of the liquid and gas pipes as shown in Fig. 7-1.

(3) Apply refrigerant oil on the fl ared seat. (Fig. 7-3)

Use the fl are nut removed from the branch box. Use of an off-the-shelf nut

may lead to a crack in the nut.

(4) Connect the refrigerant piping immediately. Always tighten the flared nuts to

the torque specified in the table 2 using a torque wrench and double spanner.

(Fig. 7-2)

Fig. 6-1

(inch)

Fig. 6-2

* Purchase an appropriate

bracket locally if the unit

is to be mounted on a

wall.

Fig. 7-1

Flare nut tightening torque

90°

±

0.5°

øA

R1/64 to R1/32

A

B

45°±2°

Table 2

Copper pipe O.D.

(mm (inch))

Flare nut O.D.

(mm (inch))

Tightening torque

(N•m (ft•lbs))

ø6.35 (1/4)

17 (43/64)

14-18 (10-13)

ø6.35 (1/4)

22 (7/8)

34-42 (25-30)

ø9.52 (3/8)

22 (7/8)

34-42 (25-30)

ø9.52 (3/8)

26 (1-3/64)

49-61 (35-44)

ø12.7 (1/2)

26 (1-3/64)

49-61 (35-44)

ø12.7 (1/2)

29 (1-9/64)

68-82 (49-59)

ø15.88 (5/8)

29 (1-9/64)

68-82 (49-59)

ø15.88 (5/8)

36 (1-27/64)

100-120 (71-87)

Flare cutting dimensions

Fig. 7-2

Caution:

Tighten the flare nut with a torque wrench in the specified method.

Overtightening will cause the flare nut to crack and it will cause refrigerant

leakage over a period of time.

Min. 1-3/16

Min. 2

Min. 2

Bracket

W

all

øA

45°±2°

R1/64 to R1/32

90° ± 0.5°

en

6

01_WG79B721H01_EN.indd 6

2019/09/09 15:36:11

007