11

GB

Caution:

Cut the tip of the indoor unit piping, remove the gas, and then remove the

brazed cap.

[Fig. 5.3.1]

B

A

A

Cut

here

B

Remove brazed cap

5.4. Insulating refrigerant pipes

Be sure to wind heat-resisting polyethylene form of more than 20 mm [13/16

in] in thickness onto both liquid and gas pipes and also put it onto the joints

between indoor unit and insulating material so that there will be no gaps. Incom-

plete insulation may cause excess condensation or heat losses. Pay careful at-

tention, particularly when insulating above the ceiling.

[Fig. 5.4.1]

F

E

C

B

A

D

A

Locally procured insulating material for pipes

B

Bind here using band or tape.

C

Do not leave any opening.

D

Lap margin: more than 40 mm [1-19/32 in]

E

,QVXODWLQJPDWHULDO¿HOGVXSSOLHG

F

Unit side insulating material

5.5. Drain piping work

1. Drain piping work

(QVXUH WKDW WKH GUDLQ SLSLQJ LV GRZQZDUG SLWFK RI PRUH WKDQ WR WKH

outdoor (discharge) side. If it is impossible to take any downward pitch, use

an optionally available drain-up mechanism to obtain a downward pitch of

more than 1/100.

(QVXUHWKDWDQ\FURVVZLVHGUDLQSLSLQJLVOHVVWKDQP>IW@,IWKHGUDLQ

piping is long, support it with metal brackets to prevent it from bending, warp-

ing, or vibrating.

&RQQHFWWKHVXSSOLHGGUDLQKRVHWRWKHGLVFKDUJHSRUWRQWKHXQLWERG\8VH

hard vinyl chloride pipes VP-25 (ø32 mm [1-1/4 in]) for drain piping (

2

).

Tighten the supplied drain hose onto the discharge port using the supplied

hose band. (For this, do not use any adhesive because the drain hose will

need to be removed for servicing at a later date.)

'RQRWXVHDQ\RGRUWUDSDURXQGWKHGLVFKDUJHSRUW

0DNHVXUHWRXVHWKHVXSSOLHGKRVHEDQG

G

WR¿[WKHGUDLQKRVHLQSODFH

Using a commercially available hose band may cause damage to the natural

drain discharge port when tightend too much, resulting in water leakage.

[Fig. 5.5.1]

(Unit: mm [in])

A

1

A

B

C

B

VP-25

D

E

G

F

2

A: 250 [9-27/32]

B: 1500-2000 [59-1/16-78-3/4]

A

Downward pitch of more than 1/100

B

Insulating

material

C

Supporting

bracket

D

Drain discharge port

E

Drain hose (200 [7-7/8] long, accessory)

F

Tie band (accessory)

G

Hose band (accessory)

$VVKRZQLQ

3

, install a collecting pipe about 100 mm [3-15/16 in] below the

drain ports and give it a downward pitch of more than 1/100. This collecting

pipe should be of VP-30.

6HWWKHHQGRIGUDLQSLSLQJLQDSODFHZLWKRXWDQ\ULVNRIRGRUJHQHUDWLRQ

'RQRWSXWWKHHQGRIGUDLQSLSLQJLQWRDQ\GUDLQZKHUHLRQLFJDVHVDUHJHQ

-

erated.

'UDLQ SLSLQJ PD\ EH LQVWDOOHG LQ DQ\ GLURZHYHU SOHDVH EH VXUH WR

observe the above instructions.

:KHQXVLQJDQRSWLRQDOO\DYDLODEOHGUDLQXSPHFKDQLVPIROORZLWVLQVWUXFWLRQ

manual regarding its installation and use.

[Fig. 5.5.2]

B

B

A

D

C

VP-30

3

A

BC

controller

B

Indoor

unit

C

Collecting

pipe

D

Please ensure this length is at least 100 mm [3-15/16 in].

2. Discharge

test

After completing drain piping work, open the BC controller panel, and test drain

discharge using a small amount of water. Also, check to see that there is no wa-

ter leakage from the connections.

3. Insulating drain pipes

3URYLGHVXI¿FLHQWLQVXODWLRQWRWKHGUDLQSLSHVMXVWDVIRUUHIULJHUDQWSLSHV

Caution:

Be sure to provide drain piping with heat inslation in order to prevent

excess condensation. Without drain piping, water may leak from the unit

causing damage to your property.

X

Consult all related regulations and power companies beforehand.

Warning:

(OHFWULFDO ZRUN VKRXOG EH KDQGOHG E\ TXDOL¿HG HOHFWULFDO HQJLQHHUV LQ DF

-

cordance with all related regulations and attached instruction manuals.

Special circuits should also be used. If there is a lack of power capacity or

DGH¿FLHQF\LQHOHFWULFDOZRUNLWPD\FDXVHDULVNRIHOHFWULFVKRFNRU¿UH

X

Connect all wires securely.

)L[ SRZHU VRXUFH ZLULQJ WR FRQWURO ER[ E\ XVLQJ EXIIHU EXVKLQJ IRU WHQVLOH

force (PG connection or the like).

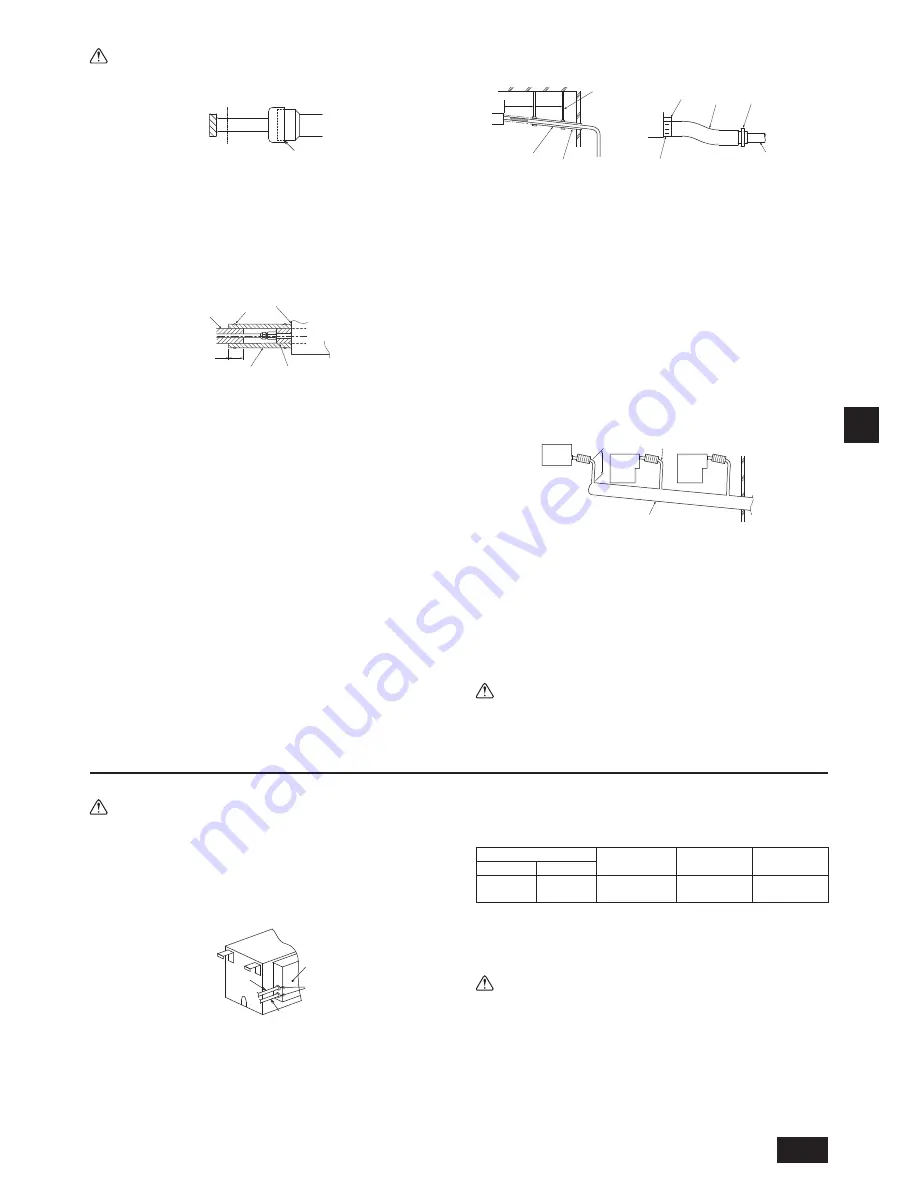

[Fig. 6.0.1]

B

A

C

D

A

Control

box

B

Power source wiring

C

ø21 mm [27/32 in] hole (closed rubber bushing)

D

Transmission

wiring

X

Never connect the power cable to the terminal board for control cables.

(Otherwise it may be broken.)

X

Be sure to wire between the control wire terminal boards for indoor

unit, outdoor unit and BC controller.

Use non-polarized 2-wire as transmission cables.

Use 2-core shielding cables (CVVS, CPEVS) of more than 1.25 mm

2

[AWG16] in

diameter as transmission cables.

The switch capacity of the main power to BC controllers and the wire size are as

follows:

Switch (A)

Molded case

circuit breaker

Earth leakage

breaker

Wire size

Capacity

Fuse

15

15

20 A

20 A 30 mA

0.1 s or less

1.5 mm

2

[AWG15]

)RURWKHUGHWDLOHGLQIRUPDWLRQUHIHUWRWKHRXWGRRUXQLWLQVWDOODWLRQPDQXDO

3RZHUVXSSO\FRUGVRIDSSOLDQFHVVKDOOQRWEHOLJKWHUWKDQGHVLJQ,(&

or 227 IEC 53.

$VZLWFKZLWKDWOHDVWPP>LQ@FRQWDFWVHSDUDWLRQLQHDFKSROHVKDOOEH

provided by the Air conditioner installation.

Caution:

Do not use anything other than the correct capacity fuse and breaker. Us-

ing fuse, conductor or copper wire with too large capacity may cause a

ULVNRIPDOIXQFWLRQRU¿UH

Ensure that the outdoor units are put to the ground. Do not connect the

earth cable to any gas pipe, water pipe, lightening rod or telephone earth

cable. Incomplete grounding may cause a risk of electric shock.

6. Electrical work