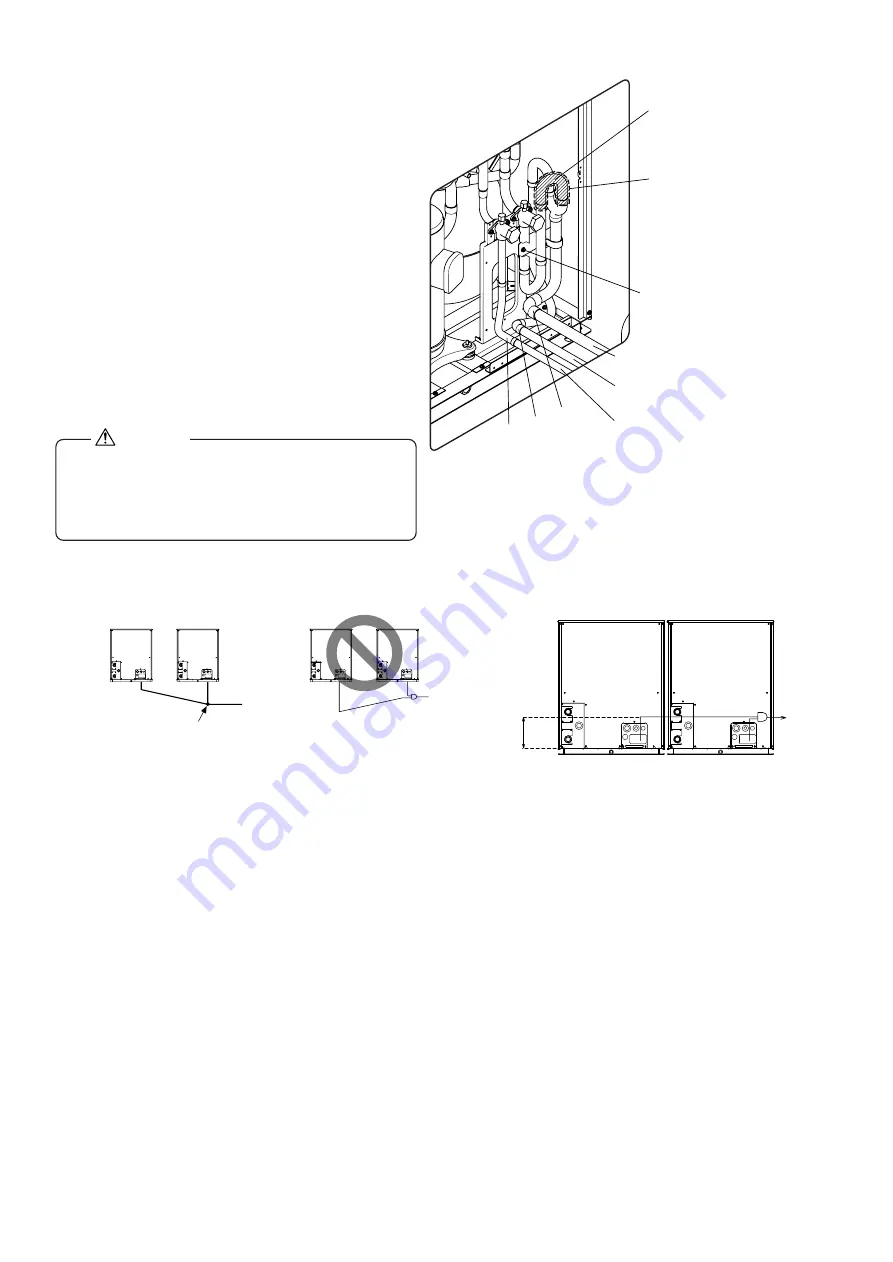

Downslope

Upward slope

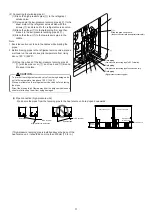

To BC controller

To BC controller

High-pressure twinning pipe

· If high-pressure twinning pipe is installed above the base of the

heat source unit, it should be no more than 200mm [7-7/8 in.].

200mm

[7-7/8 in.]

max.

High-pressure

twinning pipe

To indoor unit

Heat source unit 1

Heat source unit 2

(6) Pipe connection (high-pressure side)

· Make sure the pipes from the twinning pipe to the heat source unit are sloped downwards.

3

Field piping

(Low-pressure connecting pipe:To BC Controller)

Field piping

(Low-pressure connecting pipe:To heat source unit)

Field piping

(High-pressure connecting pipe)

1

7C

Wrap the pipe cover here.

(Keep out of contact with the adjacent sheet metal.)

3

5

4

6

· To prevent the refrigerant service valve from being damaged, do

not let its temperature rise above 120 ˚C [248˚F].

Place a wet towel on the refrigerant service valve before brazing

the pipes.

· Direct the blazing torch flame away from the adjacent cables and

sheet metal to keep them from being damaged.

CAUTION

(2) Connecting the twinning pipe kit

(1) Braze the high-pressure pipe (

6

) to the refrigerant

service valve.

(2) Screw down the low-pressure twinning pipe kit (

1

) to the

sheet metal of the refrigerant service valve with the

screws (

3

), and braze it to the refrigerant service valve.

(3) Braze the elbow (

5

) to the field-piping first, and then

braze it to the low-pressure twinning pipe kit (

1

).

(4) Braze the elbow (

4

) to the low-pressure pipe in the

middle.

Note

1. Exercise caution not to burn the cables while brazing the

pipes.

2. Before brazing pipes to the refrigerant service valve, place a

wet towel on the valve to keep its temperature from rising

above 120 ˚C [248˚F].

(5) Wrap the u-bend of the low-pressure twinning pipe kit

(

1

) with the pipe cover (

7

), and tie a band (

C

) around

it to keep it in place.