WT05688X01

4. Insulation Cover Installation

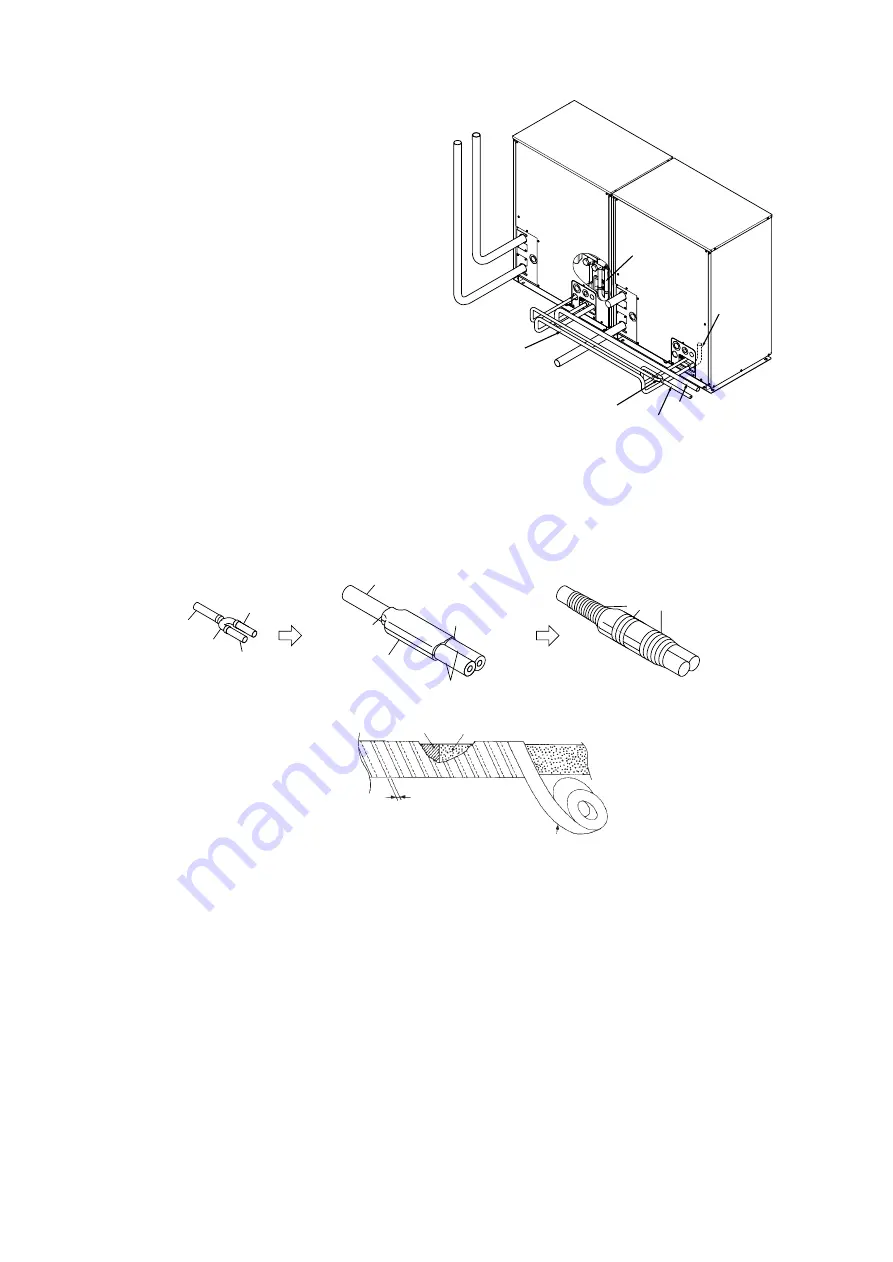

Install the insulation cover on the twinning kit after brazing the pipes and twinning kit.

Insulate all refrigerant pipes. Insulate the high-pressure and low-pressure pipes separately, and pipes located inside the unit as well as

the outside. Use heat-resistant insulation material (Heat resistant : at least 120˚C [248˚F], Thickness: high-pressure = 10 mm [13/32 in.],

low-pressure = 20 mm [13/16 in.] ). Position the edges of the insulation cover and heat-resistant insulation material so as not to leave a

gap, and then wrap the exterior perimeter of the pipe joints and middle with tape (field-supplied).

Tape (field-supplied)

Overlap margin of the tape

Insulation cover

Heat-resistant insulation material (field-supplied)

Insulation covers can shrink.

Overlap the tape as shown in the left

figure so that there will be no gap in-

between the insulation cover or

field-installed insulation material.

field-supplied pipe

Heat-resistant insulation material (field-supplied)

Heat-resistant insulation material (field-supplied)

field-supplied pipe

field-supplied pipe

2

High-pressure

twinning pipe

B

Insulation cover

Tape (field-supplied)

To be gap free

To be gap free

4

See reverse.

3. Pipe Connection Example

Connect the pipes between heat source units,

referencing the figure below.

1

Low-pressure

twinning kit

Low-pressure connecting pipe

(Between heat source units)

2

High-pressure twinning pipe

Main high-pressure pipe (To BC controller)

Main low-pressure pipe (To BC controller)

D

ID22.2 [7/8]

-ID25.4 [1]

5. Miscellaneous Notes

Secure the field-supplied pipes with a pipe cover and a cable tie in place to keep them from coming in contact with other pipes as

necessary.

Install the insulation cover so that the edges of the cover meet at the top.