11

GB

D

F

E

I

NL

GR

RU

TR

CZ

SV

HG

PO

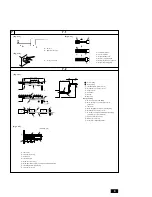

9.1. Power supply wiring

•

Power supply cords of appliances shall not be lighter than design 245 IEC 57

or 227 IEC 57.

•

A switch with at least 3 mm [1/8 in] contact separation in each pole shall be

provided by the Air conditioner installation.

Power cable size: more than 1.5 mm

2

[AWG16]

[Fig. 9.1.1] (P.4)

A

Switch 16 A

B

Overcurrent protection 16 A

C

Indoor unit

D

Total operating current be less than 16 A

E

Pull box

[Selecting non-fuse breaker (NF) or earth leakage breaker (NV)]

To select NF or NV instead of a combination of Class B fuse with switch, use the

following:

•

In the case of Class B fuse rated 15 A or 20 A,

NF model name (MITSUBISHI): NF30-CS (15 A) (20 A)

NV model name (MITSUBISHI): NV30-CA (15 A) (20 A)

Use an earth leakage breaker with a sensitivity of less than 30 mA 0.1 s.

Caution:

Do not use anything other than the correct capacity breaker and fuse. Using

fuse, wire or copper wire with too large capacity may cause a risk of mal-

function or fire.

2. Remote controller cables

Types of cables

Cable diameter

Length

MA remote controller

Sheathed 2-core cable (unshielded) CVV

0.3 to 1.25 mm

2

[AGW22 to 16]

Less than 200 m [656 ft]

M-NET remote controller

Sheathed 2-core cable (unshielded) CVV

0.3 to 1.25 mm

2

[AGW22 to 16]

Add any portion in excess of 10 m [32 ft] to within the longest allowable

transmission cable length 200 m [656 ft] (Shielding portion is more than

1.25 mm

2

[AWG16])

System configuration

For a single-refrigerant system

For a multi-refrigerant system

Transmission cable length

Less than 120 m [394 ft]

More than 120 m [394 ft]

Regardless of length

Facility example

(for noise judgment)

Types of transmission

cables

Residence or independent store

without noise

VCTF, VCTFK, CVV, CVS, VVR,

VVF, VCT or shielding wire

CVVS or CPEVS

Building, clinic, hospital or communications

station without noise supposedly generated

from inverter equipment, private power gen-

erator, high-frequency medical equipment,

radio-used communications equipment and

so on

All facilities

Shielding wire CVVS or CPEVS

Length

Less than 120 m [394 ft]

Less than 200 m [656 ft]

<Table 1>

9. Electrical wiring

6. Be sure to connect control cables to the indoor unit, remote controller, and the

outdoor unit.

7. Put the unit to the ground on the outdoor unit side.

8. Select control cables from the conditions given in page

11

.

Caution:

Be sure to put the unit to the ground on the outdoor unit side. Do not con-

nect the earth cable to any gas pipe, water pipe, lightening rod, or telephone

earth cable. Incomplete grounding may cause a risk of electric shock.

Types of control cables

1. Wiring transmission cables

•

Types of transmission cables

Design wiring in accordance with the following table <Table 1>.

•

Cable diameter

More than 1.25 mm

2

[AWG16]

Precautions on electrical wiring

Warning:

Electrical work should be done by qualified electrical engineers in accord-

ance with “Engineering Standards For Electrical Installation” and supplied

installation manuals. Special circuits should also be used. If the power cir-

cuit lacks capacity or has an installation failure, it may cause a risk of elec-

tric shock or fire.

1. Be sure to install an earth leakage breaker to the power.

2. Install the unit to prevent that any of the control circuit cables (remote control-

ler, transmission cables) is brought in direct contact with the power cable out-

side the unit.

3. Ensure that there is no slack on all wire connections.

4. Some cables (power, remote controller, transmission cables) above the ceiling

may be bitten by mouses. Use as many metal pipes as possible to insert the

cables into them for protection.

5. Never connect the power cable to leads for the transmission cables. Other-

wise the cables would be broken.

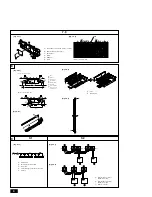

9.2. Connecting remote controller, indoor

and outdoor transmission cables

•

Connect indoor unit TB5 and outdoor unit TB3. (Non-polarized 2-wire)

The “S” on indoor unit TB5 is a shielding wire connection. For specifications

about the connecting cables, refer to the outdoor unit installation manual.

•

Install a remote controller following the manual supplied with the remote con-

troller.

•

Connect the “1” and “2” on indoor unit TB15 to a MA remote controller. (Non-

polarized 2-wire)

•

Connect the “M1” and “M2” on indoor unit TB5 to a M-NET remote controller.

(Non-polarized 2-wire)

•

Connect the remote controller’s transmission cable within 10 m [32 ft] using a

0.75mm

2

[AWG18] core cable. If the distance is more than 10 m [32 ft], use a

1.25 mm

2

[AWG16] junction cable.

[Fig. 9.2.1]

(P.4) MA Remote controller

[Fig. 9.2.2]

(P.4) M-NET Remote controller

A

Terminal block for indoor transmission cable

B

Terminal block for outdoor transmission cable

C

Remote controller

•

DC 9 to 13 V between 1 and 2 (MA remote controller)

•

DC 24 to 30 V between M1 and M2 (M-NET remote controller)

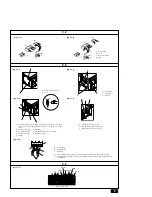

[Fig. 9.2.3]

(P.5) MA Remote controller

[Fig. 9.2.4]

(P.5) M-NET Remote controller

A

Non-polarized

B

TB15

C

Remote Controller

D

TB5

•

The MA remote controller and the M-NET remote controller cannot be used at

the same time or interchangeably.

Caution:

Install wiring so that it is not tight and under tension. Wiring under tension

may break, or overheat and burn.

01_KB79P491H01_GB.p65

6/23/09, 4:22 PM

11