12

GB

D

F

E

I

NL

P

GR

RU

TR

CZ

SV

HG

PO

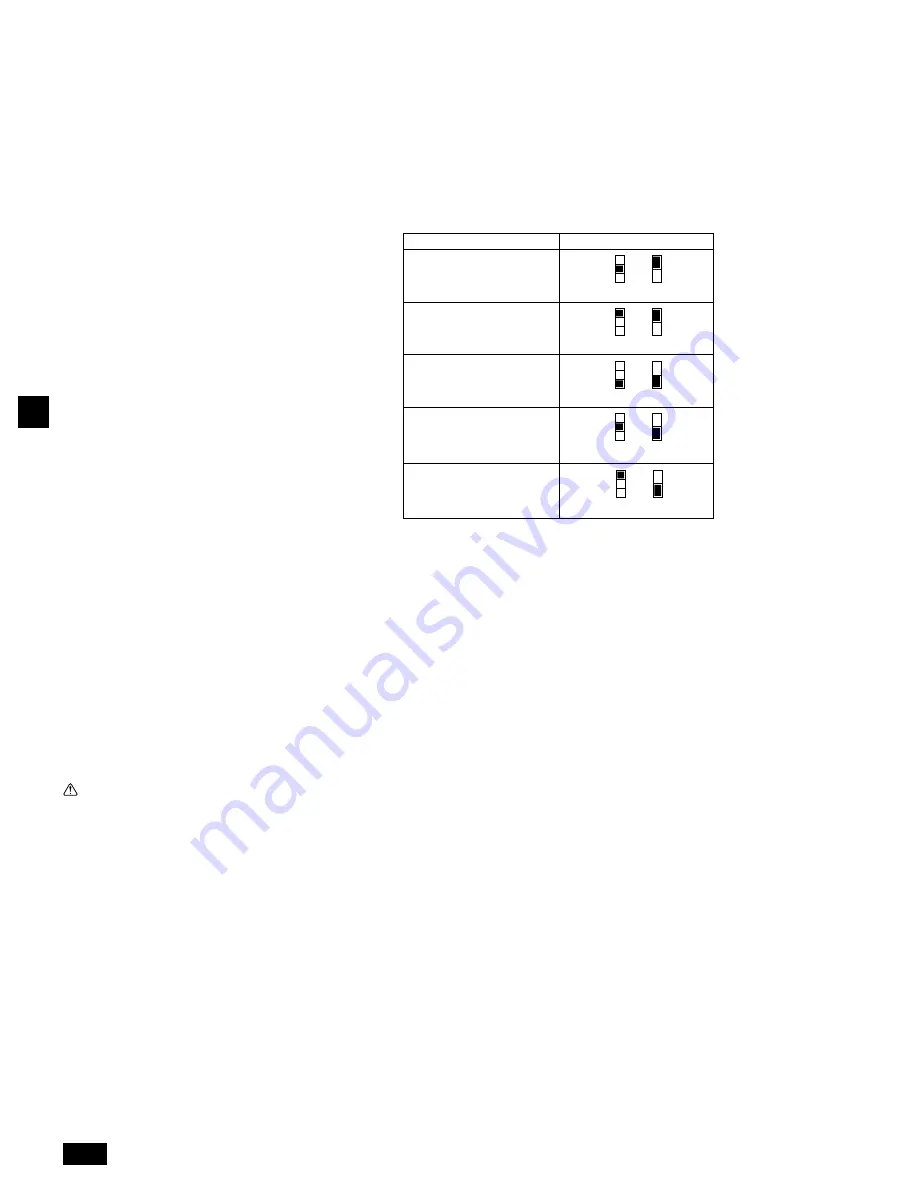

External static pressure

Switch operation

0.14 in. WG

(35 Pa)

3

2

1

SWA

SWC

SWC

3

2

1

SWA

SWC

3

2

1

SWA

SWC

3

2

1

SWA

9.5. Selecting the external static pressure

As the factory setting is for use under an external static pressure of 0.20 in. WG (50

Pa), no switch operation is needed when using under the standard condition.

9.6. Setting addresses

(Be sure to operate with the main power turned OFF.)

[Fig. 9.5.1] (P.5)

<Indoor controller board>

•

There are two types of rotary switch setting available: setting addresses 1 to 9

and over 10, and setting branch numbers.

1

How to set addresses

Example: If Address is “3”, remain SW12 (for over 10) at “0”, and match

SW11(for 1 to 9) with “3”.

2

How to set branch numbers SW14 (Series R2 only)

The branch number assigned to each indoor unit is the port number of the

BC controller to which the indoor unit is connected.

Leave it to “0” on the non-R2 series of units.

•

The rotary switches are all set to “0” when shipped from the factory. These

switches can be used to set unit addresses and branch numbers at will.

•

The determination of indoor unit addresses varies with the system at site. Set

them referring to the Data Book.

9.7. Sensing room temperature with the

built-in sensor in a remote controller

If you want to sense room temperature with the built-in sensor in a remote control-

ler, set SW1-1 on the control board to “ON”. The setting of SW1-7 and SW1-8 as

necessary also makes it possible to adjust the air flow at a time when the heating

thermometer is OFF.

9.8. Changing the power voltage setting

(Be sure to operate with the main power turned OFF.)

[Fig. 9.5.1] (P.5)

Please set the switch SW5 according to the power voltage.

•

Set SW5 to 240V side when the power supply is 230 volts.

•

When the power supply is 208 volts, set SW5 to 220V side.

SWC

3

2

1

SWA

1

2

1

2

1

2

1

2

1

2

[Fig. 9.5.1] (P.5)

<Indoor controller board>

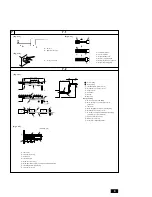

9.3. Connecting electrical connections

Please identify the model name of the operation manual attached on the terminal

box cover with that shown on the rating name plate.

1. Remove the screw (1pc) holding the cover to dismount the cover.

[Fig. 9.3.1] (P.5)

A

Screw holding cover (1pc)

B

Cover

2. Open knockout holes

(Recommend to use a screwdriver or the like for this work.)

[Fig. 9.3.2] (P.5)

C

Terminal box

D

Knockout hole

E

Remove

3. Fix power source wiring to terminal box by using buffer bushing for tensile

force. (PG connection or the like.) Connect transmission wiring to transmis-

sion terminal block through the knockout hole of terminal box using ordinary

bushing.

[Fig. 9.3.3] (P.5)

F

Use PG bushing to keep the weight of the cable and external force from being

applied to the power supply terminal connector. Use a cable tie to secure the

cable.

G

Power source wiring

H

Use ordinary bushing

I

Transmission wiring

J

Conduit

K

Side frame

L

Knockout hole (for power source wiring)

M

Washer (accessory)

4. Connect the power source, Earth, transmission and remote controller wiring.

The dismounting of the terminal box is not needed.

[Fig. 9.3.4] (P.5)

N

Terminal block for power source

O

Terminal block for indoor transmission

P

Terminal block for remote controller

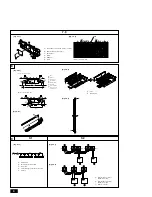

[Shield wire connection]

[Fig. 9.3.5] (P.5)

A

Terminal block

B

Round terminal

C

Shield wire

D

The earth wire from two cables are connected together to the S terminal. (Dead-

end connection)

E

Insulation tape (To keep the earth wire of the shielded cable from coming in con-

tact with the transmission terminal)

5. After wiring is complete, make sure again that there is no slack on the connec-

tions, and attach the cover onto the terminal box in the reverse order of re-

moval.

Notes:

•

Do not pinch the cables or wires when attaching the terminal box cover.

Doing so may cause a risk of disconnection.

•

When accommodating the terminal box, make sure that the connectors

on the box side are not removed. If removed, it cannot operate normally.

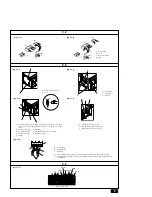

9.4. External I/O specifications

Caution:

1. Wiring should be covered by insulation tube with supplementary insula-

tion.

2. Use relays or switches with IEC or equivalent standard.

3. The electric strength between accessible parts and control circuit should

have 2750 V or more.

0.20 in. WG

(50 Pa)

0.28 in. WG

(70 Pa)

0.60 in. WG

(150 Pa)

0.40 in. WG

(100 Pa)

01_KB79P491H01_GB.p65

6/23/09, 4:22 PM

12