8

GB

D

F

E

I

NL

P

GR

RU

TR

CZ

SV

HG

PO

4. Fixing hanging bolts

4.1

Fixing hanging bolts

[Fig. 4.1.1] (P.2)

A

Center of gravity

(Give site of suspension strong structure.)

•

Do not install unit at a site where fire detector is located at the supply air side.

(Fire detector may operate erroneously due to the heated air supplied during

heating operation.)

•

When special chemical product may scatter around such as site chemical plants

and hospitals, full investigation is required before installing unit. (The plastic

components may be damaged depending on the chemical product applied.)

•

If the unit is run for long hours when the air above the ceiling is at high tem-

perature/high humidity (due point above 26 °C [79 °F]), due condensation may

be produced in the indoor unit. When operating the units in this condition, add

insulation material (10-20 mm [13/32 to 13/16 in]) to the entire surface of the

indoor unit to avoid due condensation.

3.1. Install the indoor unit on a ceiling strong

enough to sustain its weight

Warning:

The unit must be securely installed on a structure that can sustain its weight.

If the unit is mounted on an unstable structure, it may fall down causing

injuries.

3.2. Securing installation and service space

•

Select the optimum direction of supply airflow according to the configuration of

the room and the installation position.

•

As the piping and wiring are connected at the bottom and side surfaces, and

the maintenance is made at the same surfaces, allow a proper space properly.

For the efficient suspension work and safety, provide a space as much as

possible.

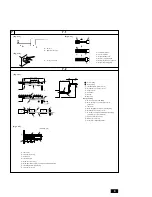

[Fig. 3.2.1] (P.2)

A

Access door

B

Electrical parts box

C

Air inlet

D

Air outlet

E

Ceiling surface

F

Service space (viewed from the side)

G

Service space (viewed from the direction of arrow)

1

600 mm [23-5/8 in] or more

2

100 mm [3-15/16 in] or more

3

20 mm [13/16 in] or more

4

300 mm [11-13/16 in] or more

3.3. Combining indoor units with outdoor

units

For combining indoor units with outdoor units, refer to the outdoor unit installation

manual.

Hanging structure

•

Ceiling: The ceiling structure varies from building to one another. For detailed

information, consult your construction company.

•

If necessary, reinforce the hanging bolts with anti-quake supporting members

as countermeasures against earthquakes.

* Use M10 for hanging bolts and anti-quake supporting members (field supply).

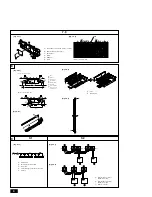

5. Installing the unit

5.1. Hanging the unit body

Bring the indoor unit to an installation site as it is packed.

To hang the indoor unit, use a lifting machine to lift and pass through the

hanging bolts.

[Fig. 5.1.1] (P.2)

A

Unit body

B

Lifting machine

[Fig. 5.1.2] (P.2)

C

Nuts (field supply)

D

Washers (field supply)

E

M10 hanging bolt (field supply)

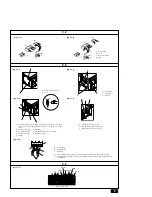

5.2. Confirming the unit’s position and fix-

ing hanging bolts

Use the gage supplied with the panel to confirm that the unit body and

hanging bolts are positioned in place. If they are not positioned in place,

it may result in dew drops due to wind leak. Be sure to check the positional

relationship.

Use a level to check that the surface indicated by

A

A

A

A

A

is at level. Ensure

that the hanging bolt nuts are tightened to fix the hanging bolts.

To ensure that drain is discharged, be sure to hang the unit at level using

a level.

[Fig. 5.2.1] (P.2)

A

Indoor unit’s bottom surface

Caution:

Install the unit in horizontal position. If the side with drain port is installed

higher, water leakage may be caused.

6. Refrigerant pipe and drain pipe specifications

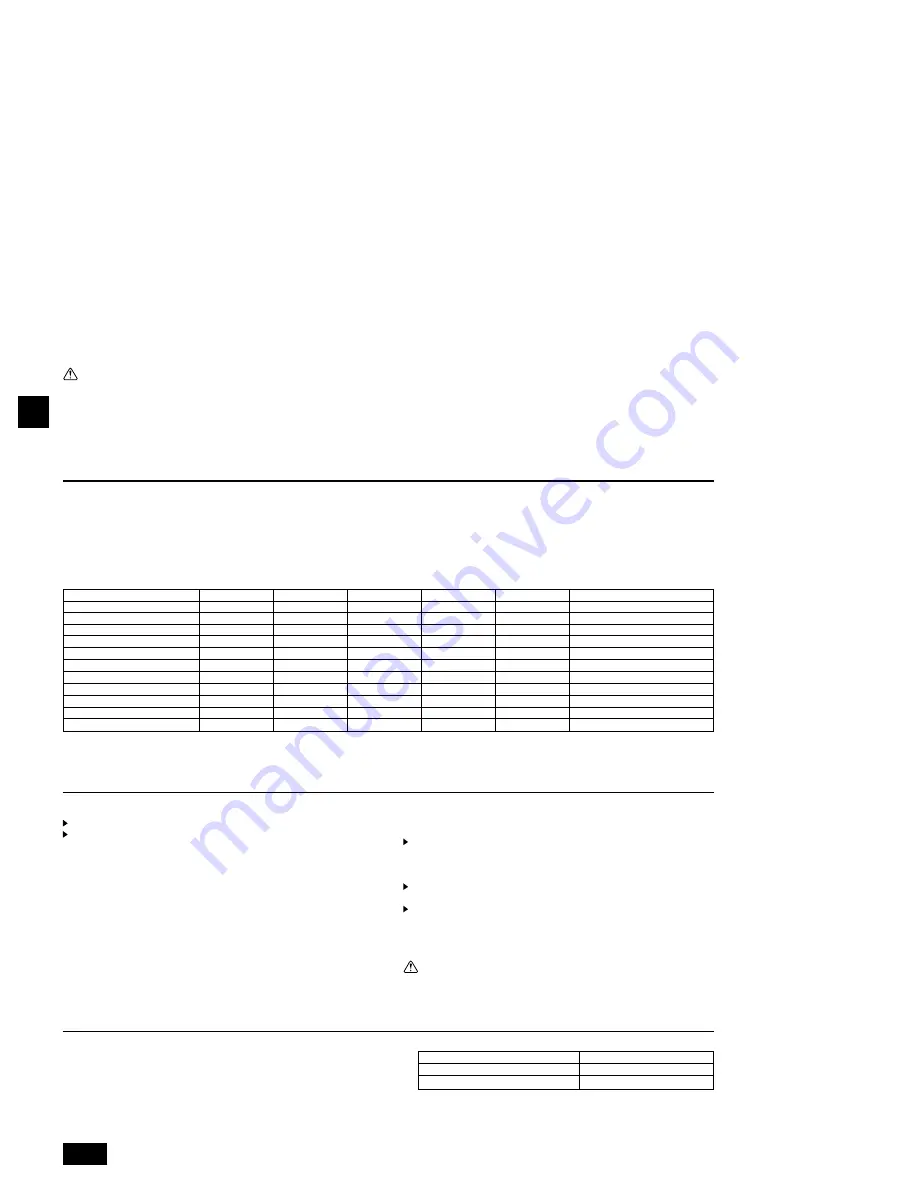

Center of gravity and Product Weight

To avoid dew drops, provide sufficient antisweating and insulating work to the re-

frigerant and drain pipes.

When using commercially available refrigerant pipes, be sure to wind commer-

cially available insulating material (with a heat-resisting temperature of more than

100 °C [212 °F] and thickness given below) onto both liquid and gas pipes.

Insulate all indoor pipes with form polyethylene insulation with a minimum density

of 0.03 and a thickness as specified in the table below.

1

Select the thickness of insulating material by pipe size.

Pipe size

Insulating material’s thickness

6.4 mm to 25.4 mm [1/4 to 1 in]

More than 10 mm [7/16 in]

28.6 mm to 38.1 mm [1-1/8 to 1-1/2 in]

More than 15 mm [5/8 in]

2

If the unit is used on the highest story of a building and under conditions of

high temperature and humidity, it is necessary to use pipe size and insulating

material’s thickness more than those given in the table above.

3

If there are customer’s specifications, simply follow them.

Model name

PEFY-P06NMAU-E

PEFY-P08NMAU-E

PEFY-P12NMAU-E

PEFY-P15NMAU-E

PEFY-P18NMAU-E

PEFY-P24NMAU-E

PEFY-P27NMAU-E

PEFY-P30NMAU-E

PEFY-P36NMAU-E

PEFY-P48NMAU-E

PEFY-P54NMAU-E

W (mm [in])

643 [25-5/16]

643 [25-5/16]

643 [25-5/16]

643 [25-5/16]

643 [25-5/16]

643 [25-5/16]

643 [25-5/16]

643 [25-5/16]

643 [25-5/16]

643 [25-5/16]

643 [25-5/16]

L (mm [in])

754 [29-11/16]

754 [29-11/16]

754 [29-11/16]

954 [37-9/16]

954 [37-9/16]

1154 [45-7/16]

1154 [45-7/16]

1154 [45-7/16]

1454 [57-1/4]

1454 [57-1/4]

1654 [65-1/8]

X (mm [in])

330 [13]

330 [13]

330 [13]

340 [13-3/8]

340 [13-3/8]

325 [12-13/16]

325 [12-13/16]

325 [12-13/16]

330 [13]

330 [13]

332 [13-1/16]

Y (mm [in])

300 [11-13/16]

300 [11-13/16]

300 [11-13/16]

375 [14-3/4]

375 [14-3/4]

525 [20-11/16]

525 [20-11/16]

525 [20-11/16]

675 [26-9/16]

675 [26-9/16]

725 [28-9/16]

Z (mm [in])

130 [5-1/8]

130 [5-1/8]

130 [5-1/8]

130 [5-1/8]

130 [5-1/8]

130 [5-1/8]

130 [5-1/8]

130 [5-1/8]

130 [5-1/8]

130 [5-1/8]

130 [5-1/8]

Product Weight (kg [lb])

23 [51]

23 [51]

23 [51]

26 [58]

26 [58]

32 [71]

32 [71]

32 [71]

42 [93]

42 [93]

46 [102]

01_KB79P491H01_GB.p65

6/23/09, 4:22 PM

8