8

GB

D

F

E

I

NL

P

GR

RU

TR

CZ

SV

HG

PO

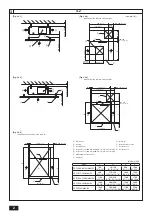

2. Indoor unit accessories

The unit is provided with the following accessories:

Part No.

Accessories

Qty

1

Tie band

4

2

Drain hose

2

3

Washer (square)

8

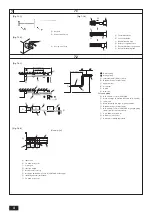

3. Selecting an installation site

• Select a site with sturdy fixed surface sufficiently durable against the weight of

unit.

• Before installing unit, the routing to carry in unit to the installation site should

be determined.

• Select a site where the unit is not affected by entering air.

• Select a site where the flow of supply and return air is not blocked.

• Select a site where refrigerant piping can easily be led to the outside.

• Select a site which allows the supply air to be distributed fully in room.

• Do not install unit at a site with oil splashing or steam in much quantity.

• Do not install unit at a site where combustible gas may generate, flow in,

stagnate or leak.

• Do not install unit at a site where equipment generating high frequency waves

(a high frequency wave welder for example) is provided.

• Do not install unit at a site where fire detector is located at the supply air side.

(Fire detector may operate erroneously due to the heated air supplied during

heating operation.)

• When special chemical product may scatter around such as site chemical plants

and hospitals, full investigation is required before installing unit. (The plastic

components may be damaged depending on the chemical product applied.)

• Use refrigerant piping made of C1220 (Cu-DHP) phosphorus deoxidized

copper as specified in the JIS H3300 “Copper and copper alloy seamless

pipes and tubes”. In addition, be sure that the inner and outer surfaces

of the pipes are clean and free of hazardous sulphur, oxides, dust/dirt,

shaving particles, oils, moisture, or any other contaminant.

- Contaminants on the inside of the refrigerant piping may cause the refrigerant

residual oil to deteriorate.

• Store the piping to be used during installation indoors and keep both

ends of the piping sealed until just before brazing. (Store elbows and

other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and

compressor trouble may result.

• Use liquid refrigerant to fill the system.

- If gas refrigerant is used to seal the system, the composition of the refrigerant

in the cylinder will change and performance may drop.

• Do not use a refrigerant other than R410A.

- If another refrigerant (R22, etc.) is used, the chlorine in the refrigerant may

cause the refrigerator oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve.

- The vacuum pump oil may flow back into the refrigerant cycle and cause the

refrigerator oil to deteriorate.

• Do not use the following tools that are used with conventional refriger-

ants.

(Gauge manifold, charge hose, gas leak detector, reverse flow check valve,

refrigerant charge base, vacuum gauge, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerator oil are mixed in the R410A,

the refrigerant may deteriorated.

- If water is mixed in the R410A, the refrigerator oil may deteriorate.

- Since R410A does not contain any chlorine, gas leak detectors for conven-

tional refrigerants will not react to it.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerant may dete-

riorate.

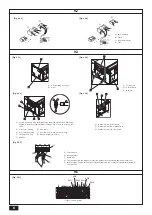

1.3. Before getting installed

Caution:

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion may result.

• Do not use the air conditioner where food, pets, plants, precision instru-

ments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the air conditioner in special environments.

- Oil, steam, sulfuric smoke, etc. can significantly reduce the performance of

the air conditioner or damage its parts.

• When installing the unit in a hospital, communication station, or similar

place, provide sufficient protection against noise.

- The inverter equipment, private power generator, high-frequency medical

equipment, or radio communication equipment may cause the air conditioner

to operate erroneously, or fail to operate. On the other hand, the air conditioner

may affect such equipment by creating noise that disturbs medical treatment

or image broadcasting.

• Do not install the unit on a structure that may cause leakage.

- When the room humidity exceeds 80% or when the drain pipe is clogged,

condensation may drip from the indoor unit. Perform collective drainage work

together with the outdoor unit, as required.

• The indoor models should be installed the ceiling over than 2.5 m from

floor.

1.4. Before getting installed (moved) - elec-

trical work

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning rods, or

telephone ground lines. Improper grounding may result in electric shock.

• Install the power cable so that tension is not applied to the cable.

- Tension may cause the cable to break and generate heat and cause a fire.

• Install an leak circuit breaker, as required.

- If an leak circuit breaker is not installed, electric shock may result.

• Use power line cables of sufficient current carrying capacity and rating.

- Cables that are too small may leak, generate heat, and cause a fire.

• Use only a circuit breaker and fuse of the specified capacity.

- A fuse or circuit breaker of a larger capacity or a steel or copper wire may

result in a general unit failure or fire.

• Do not wash the air conditioner units.

- Washing them may cause an electric shock.

• Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause personal injury

or property damage.

• Install the drain piping according to this Installation Manual to ensure

proper drainage. Wrap thermal insulation around the pipes to prevent

condensation.

- Improper drain piping may cause water leakage and damage to furniture and

other possessions.

• Be very careful about product transportation.

- Only one person should not carry the product if it weighs more than 20 kg

[45 LBS].

- Some products use PP bands for packaging. Do not use any PP bands for

a means of transportation. It is dangerous.

- Do not touch the heat exchanger fins. Doing so may cut your fingers.

- When transporting the outdoor unit, suspend it at the specified positions on

the unit base. Also support the outdoor unit at four points so that it cannot

slip sideways.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may cause

stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that children will not

play with them. If children play with a plastic bag which was not torn apart,

they face the risk of suffocation.

1.5. Before starting the test run

Caution:

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch can

result in severe damage to internal parts. Keep the power switch turned on

during the operational season.

• Do not touch the switches with wet fingers.

- Touching a switch with wet fingers can cause electric shock.

• Do not touch the refrigerant pipes during and immediately after opera-

tion.

- During and immediately after operation, the refrigerant pipes are may be

hot and may be cold, depending on the condition of the refrigerant flowing

through the refrigerant piping, compressor, and other refrigerant cycle parts.

Your hands may suffer burns or frostbite if you touch the refrigerant pipes.

• Do not operate the air conditioner with the panels and guards removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Always wait at least five minutes before turning off the power. Otherwise,

water leakage and trouble may occur.

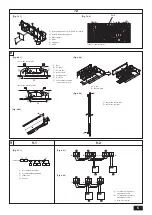

Part No.

Accessories

Qty

4

Installation manual

1

5

Operation manual

1

6

Washer (round)

2