[

III

Specfications ]

- 5 -

HWE08010

GB

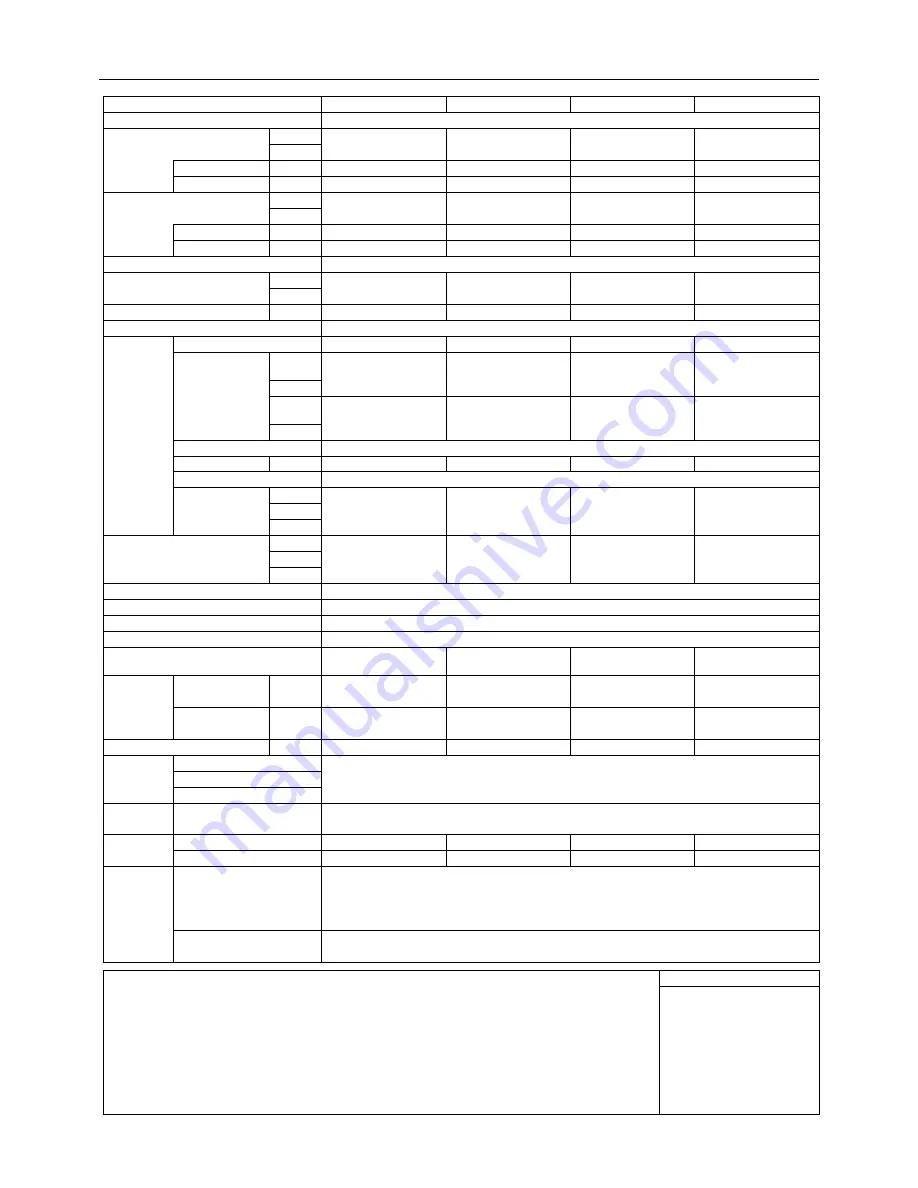

Model

PEFY-P18NMSU-E

PEFY-P24NMSU-E

Power source

1-phase 208/230V 60Hz

Cooling capacity

*1

BTU / h

18,000

24,000

(Nominal)

*1

kW 5.3

7.0

Power input

kW

0.09/0.09

0.12/0.12

Current input

A

0.74/0.70

0.98/0.93

Heating capacity

*2

BTU / h

20,000

27,000

(Nominal)

*2

kW 5.9

7.9

Power input

kW

0.07/0.07

0.10/0.10

Current input

A

0.64/0.60

0.88/0.83

External finish

Galvanized

External dimension H x W x D

in.

7-7/8 x 39 x 27-9/16

7-7/8 x 46-7/8 x 27-9/16

mm

200 x 990 x 700

200 x 1190 x 700

Net weight

lbs (kg)

54(24)

62(28)

Heat exchanger

Cross fin(Aluminium fin and copper tube)

FAN

Type x Quantity

Sirocco fan x 3

Sirocco fan x 4

External

in.WG

0.02-0.06-0.14-0.20

(208V)

0.02-0.06-0.14-0.20

(208V)

static press

Pa

5-15-35-50

5-15-35-50

in.WG

0.02-0.06-0.14-0.20

(230V)

0.02-0.06-0.14-

0.20(230V)

Pa

5-15-35-50

5-15-35-50

Motor type

DC brushless motor

Motor output

kW

0.096

0.096

Driving mechanism

Direct-driven

Airflow rate

cfm

353-441-529

423-565-706

(Low-Mid-High)

m3 / min

10-12.5-15

12-16-20

L / s

167-208-250

200-267-333

Sound pressure level

dB <A>

30-34-37 (208V)

30-35-40 (208V)

(Low-Mid-High)

dB <A>

30-34-37 (230V)

30-35-40 (230V)

(measured in anechoic room)

dB <A>

-

-

Insulation material

Polystyrene foam,Polyethylene foam,Urethane foam

Air filter

PP Honeycomb fabric (washable)

Protection device

Fuse

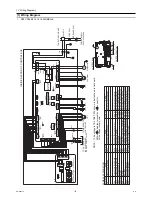

Refrigerant control device

LEV

Connectable outdoor unit

R410A,R22 CITY

MULTI

R410A,R22 CITY

MULTI

Diameter of

Liquid

(R410A)

in. (mm)

1/4 (6.35) Brazed

3/8 (9.52) Brazed

refrigerant

(R22 )

3/8 (9.52) Brazed

3/8 (9.52) Brazed

pipe

Gas

(R410A)

in. (mm)

1/2 (12.7) Brazed

5/8 (15.88) Brazed

(O.D.)

(R22 )

5/8 (15.88) Brazed

5/8 (15.88) Brazed

Diameter of drain pipe

in. (mm)

O.D. 1-1/4(32)

O.D. 1-1/4(32)

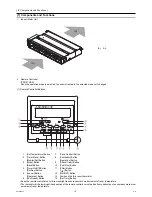

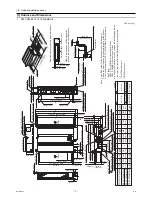

Drawing

External WKB94L522

Wiring WKB94L523

Refrigerant cycle

-

Standard

Document

Installation Manual, Instruction Book

attachment

Accessory

Drain hose (flexible joint)

Optional External

heater

adaptor

PAC-YU25HT

PAC-YU25HT

parts

Remark

Installation

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, and other

items shall be referred to the Installation Manual.

Note :

*1 Nominal cooling conditions

*2 Nominal heating conditions

Unit convertor

Indoor :

80degF D.B. / 67degF W.B.

70degF D.B.

kcal/h = kW x 860

(26.7degC D.B. / 19.4degC W.B.)

(21.1degC D.B.)

BTU/h = kW x 3,412

Outdoor :

95degF D.B.

47degF D.B. / 43degF W.B.

cfm = m3/min x 35.31

(35degC D.B.)

(8.3degC D.B. / 6.1degC W.B.)

lbs = kg / 0.4536

Pipe length :

25 ft. (7.6 m)

25 ft. (7.6 m)

Level difference :

0 ft. (0 m)

0 ft. (0 m)

*Above specification data is

*The external static pressure is set to 15 Pa at factory shipment.

subject to rounding variation.

*Due to continuing improvement, above specification may be subject to change without notice.

Summary of Contents for City Multi PEFY-P06NMSU-E

Page 5: ...iv HWE08010 GB ...

Page 7: ...HWE08010 GB ...