10

GB

[Fig. 7.2.3] (P.3)

Note:

*1. Connection of multiple indoor units with one connection (or joint pipe)

•

Total capacity of connectable indoor units: Less than 80

•

Number of connectable indoor units: Maximum 3 Sets

•

Selection of water piping

Select the size according to the total capacity of indoor units to be installed down-

stream.

•

Please group units that operate on 1 branch.

11. Please refer to the [Fig. 7.2.4] when connecting the water supply.

[Fig. 7.2.4] (P.4)

12. Install a shut off valve and strainer in a place that is easy to operate and makes

maintenance work easy.

13. Apply insulation to the indoor unit pipework, strainer, shut off valve, and pressure

reducing valve.

14. Please do not use a corrosion inhibitor in the water system.

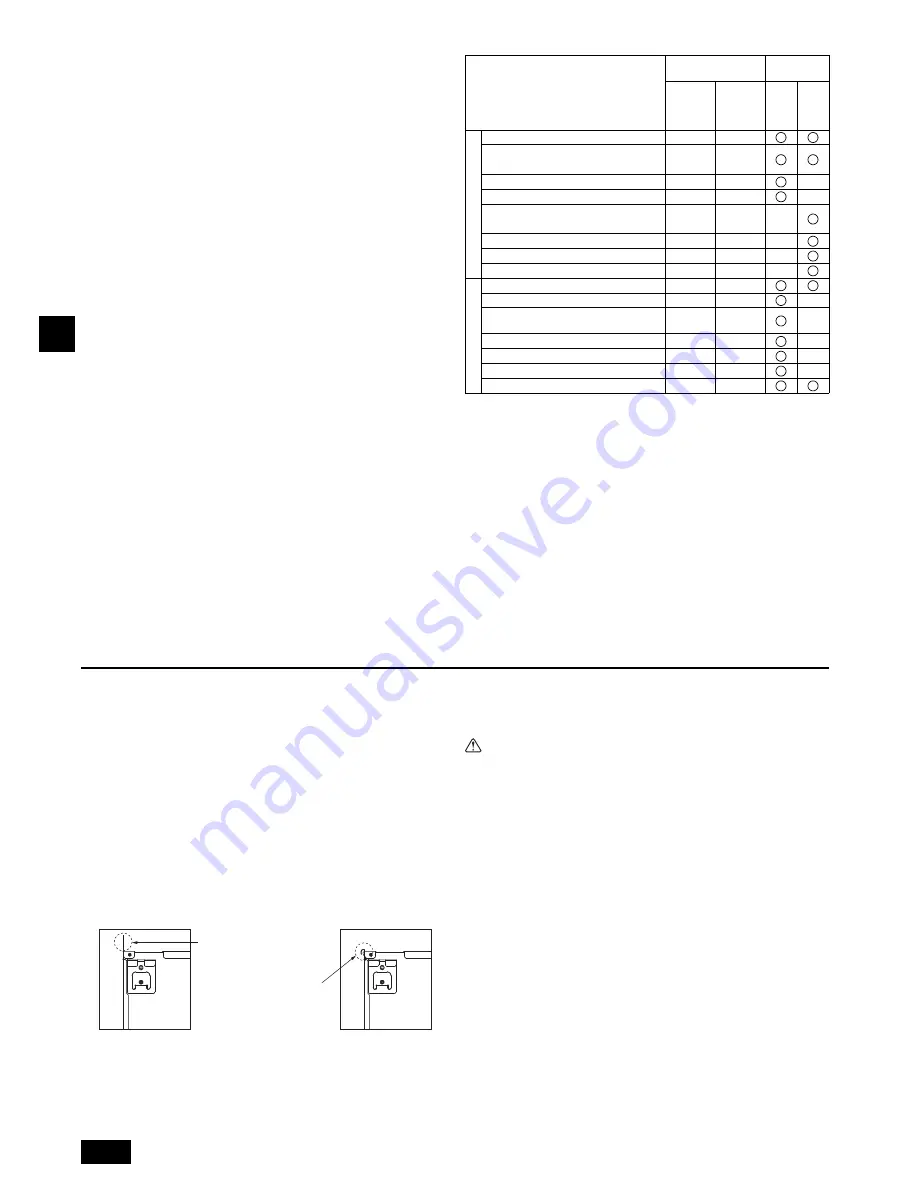

7.3. Water treatment and quality control

To preserve water quality, use the closed type of water circuit. When the circulating

water quality is poor, the water heat exchanger can develop scales, leading to a

reduction in heat-exchange power and possible corrosion. Pay careful attention to

water processing and water quality control when installing the water circulation sys-

tem.

•

Removing of foreign objects or impurities within the pipes.

During installation, make sure that foreign objects, such as welding fragments,

sealant particles, or rust, do not enter the pipes.

•

Water Quality Processing

2

Water quality standard

8. Duct work

•

In connecting duct, insert canvas duct between unit and duct.

•

Use incombustible material for duct parts.

•

Provide full insulation to inlet duct flange and outlet duct to prevent condensation.

•

Be sure to change the position of air filter to the position where it can be serviced.

[Fig. 8.0.1] (P.4)

•

Procedure for changing the rear inlet to the bottom inlet.

[Fig. 8.0.2] (P.4)

1. Remove air filter. (First remove filter lock screw.)

2. Remove the bottom plate.

3. Fit the bottom plate to the rear of the body.

[Fig. 8.0.3] (P.4)

(Position of lug-holes on the plate are different from those for rear inlet.)

4. Fit filter to the underside of the body.

(Be careful of which side of the filter to fit.)

[Fig. 8.0.4] (P.4)

[Fig. 8.0.4] (P.4)

Caution:

•

Inlet duct of 850 mm or more should be construted.

To connect the air conditioner main body and the duct for potential equali-

zation.

•

To reduce the risk of injury from metal sheet edges, wear protective gloves.

•

To connect the air conditioner main body and the duct for potential equali-

zation.

•

The noise from the intake will increase dramatically if intake is fitted

directly beneath the main body. Intake should therefore be installed as far

away from the main body as possible.

Particular care is required when using it with bottom inlet specifications.

•

Install sufficient thermal insulation to prevent condensation forming on

outlet duct flanges and outlet ducts.

•

Keep the distance between the inlet grille and the fan over 850 mm.

If it is less than 850 mm, install a safety guard not to touch the fan.

•

To avoid electrical noise interference, do not run transmission lines at the

bottom of the unit.

A

To outdoor unit

B

End connection (brazing)

C

HBC controller

D

Indoor unit

E

Twinning pipe (field supply)

F

Up to three units for 1 branch hole; total capacity: below 80 (but in same mode, cool-

ing/heating)

A

Indoor unit

B

Water pipe: From HBC unit

C

Water pipe: To HBC unit

D

Strainer (40 mesh or more)

(field supply)

E

Shut off valve

(field supply)

1

Depending on the quality of the cold-temperature water used in the aircondi-

tioner, the copper piping of the heat exchanger may corrode.

Regular water quality processing is recommended.

If a water supply tank is installed, keep air contact to a minimum, and keep

the level of dissolved oxygen in the water no higher than 1mg/

ℓ

.

Items

Low to mid-range

temperature water system

Tendency

Recirculating

water

[20<T<60°C]

[68<T<140°F]

Make-up

water

Corrosive

Scale-

forming

pH (25°C) [77°F]

7.0 ~ 8.0

7.0 ~ 8.0

Electric conductivity

(mS/m) (25°C) [77°F]

30 or less

[300 or less]

30 or less

[300 or less]

(µ s/cm) (25°C) [77°F]

Chloride ion

(mg Cl-/

ℓ

) 50 or less 50 or less

Sulfate ion

(mg SO4

2-

/

ℓ

) 50 or less 50 or less

Acid consumption (pH4.8)

50 or less 50 or less

(mg CaCO

3

/

ℓ

)

Total hardness

(mg CaCO

3

/

ℓ

) 70 or less 70 or less

Calcium hardness

(mg CaCO

3

/

ℓ

) 50 or less 50 or less

Ionic silica

(mg SiO

2

/

ℓ

) 30 or less 30 or less

Iron

(mg Fe/

ℓ

) 1.0 or less 0.3 or less

Copper

(mg Cu/

ℓ

) 1.0 or less 0.1 or less

Sulfide ion

(mg S

2-

/

ℓ

)

not to be

detected

not to be

detected

Ammonium ion

(mg NH

4

+

/

ℓ

) 0.3 or less 0.1 or less

Residual chlorine

(mg Cl/

ℓ

) 0.25 or less 0.3 or less

Free carbon dioxide

(mg CO

2

/

ℓ

) 0.4 or less 4.0 or less

Ryzner stability inde

6.0 ~ 7.0

–

Reference : Guideline of Water Quality for Refrigeration and Air Conditioning

Equipment. (JRA GL02E-1994)

3

Consult with a specialist about water quality control methods and calculations

before using anti-corrosive solutions.

4

When replacing a previously installed air conditioning device (even when

only the heat exchanger is being replaced), first conduct a water quality anal-

ysis and check for possible corrosion.

Corrosion can occur in cold-water systems even if there has been no prior

signs of corrosion.

If the water quality level has dropped, adjust water quality before replacing

the unit.

S

tan

dard

it

ems

R

e

fe

re

nc

e i

te

m

s

<A> In case of rear inlet

<B> In case of bottom inlet

A

Duct

B

Air inlet

C

Access door

D

Canvas duct

E

Ceiling surface

F

Air outlet

G

Leave distance enough to prevent short cycle

A

Filter

B

Bottom plate

When the plate is attached on

the rear side, it exceeds the

height of the rear body panel.

Replicate the plate along the slit

when there is not enough room

above for the entire unit.

C

Nail for the bottom inlet

D

Nail for the rear inlet

02_WT06410_GB.fm Page 10 Friday, November 25, 2011 3:59 PM