7

GB

1.3. Before getting installed (moved) - electri-

cal work

Caution:

•

Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning rods, or tele-

phone ground lines. Improper grounding may result in electric shock.

•

Install the power cable so that tension is not applied to the cable.

- Tension may cause the cable to break and generate heat and cause a fire.

•

Install an leak circuit breaker, as required.

- If an leak circuit breaker is not installed, electric shock may result.

•

Use power line cables of sufficient current carrying capacity and rating.

- Cables that are too small may leak, generate heat, and cause a fire.

•

Use only a circuit breaker and fuse of the specified capacity.

- A fuse or circuit breaker of a larger capacity or a steel or copper wire may result

in a general unit failure or fire.

•

Do not wash the air conditioner units.

- Washing them may cause an electric shock.

•

Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause personal injury or

property damage.

•

Install the drain piping according to this Installation Manual to ensure

proper drainage. Wrap thermal insulation around the pipes to prevent con-

densation.

- Improper drain piping may cause water leakage and damage to furniture and

other possessions.

•

Be very careful about product transportation.

- Only one person should not carry the product if it weighs more than 20 kg.

- Some products use PP bands for packaging. Do not use any PP bands for a

means of transportation. It is dangerous.

- Do not touch the heat exchanger fins. Doing so may cut your fingers.

- When transporting the outdoor unit, suspend it at the specified positions on the

unit base. Also support the outdoor unit at four points so that it cannot slip side-

ways.

•

Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may cause

stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that children will not play

with them. If children play with a plastic bag which was not torn apart, they face

the risk of suffocation.

1.4. Before starting the test run

Caution:

•

Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch can

result in severe damage to internal parts. Keep the power switch turned on dur-

ing the operational season.

•

Do not touch the switches with wet fingers.

- Touching a switch with wet fingers can cause electric shock.

•

Do not operate the air conditioner with the panels and guards removed.

- Rotating, hot, or high-voltage parts can cause injuries.

•

Do not turn off the power immediately after stopping operation.

- Always wait at least five minutes before turning off the power. Otherwise, water

leakage and trouble may occur.

•

When water has been supplied to the water pipework, purge the system of air.

The details of air purging can be found separately in the water circuit mainte-

nance manual.

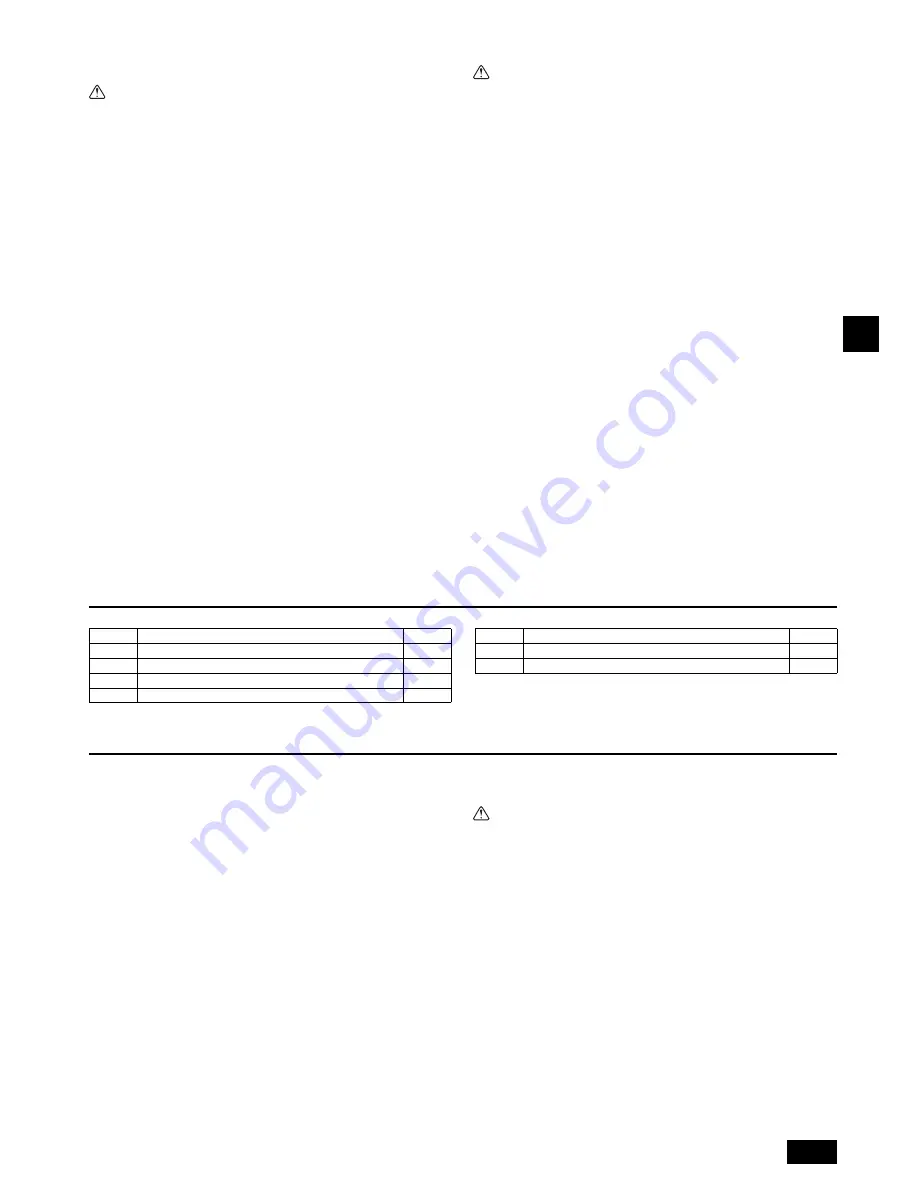

2. Indoor unit accessories

The unit is provided with the following accessories:

3. Selecting an installation site

•

Select a site with sturdy fixed surface sufficiently durable against the weight of

unit.

•

Before installing unit, the routing to carry in unit to the installation site should be

determined.

•

Select a site where the unit is not affected by entering air.

•

Select a site where the flow of supply and return air is not blocked.

•

Select a site where refrigerant piping can easily be led to the outside.

•

Select a site which allows the supply air to be distributed fully in room.

•

Do not install unit at a site with oil splashing or steam in much quantity.

•

Do not install unit at a site where combustible gas may generate, flow in, stag-

nate or leak.

•

Do not install unit at a site where equipment generating high frequency waves (a

high frequency wave welder for example) is provided.

•

Do not install unit at a site where fire detector is located at the supply air side.

(Fire detector may operate erroneously due to the heated air supplied during

heating operation.)

•

When special chemical product may scatter around such as site chemical plants

and hospitals, full investigation is required before installing unit. (The plastic com-

ponents may be damaged depending on the chemical product applied.)

•

If the unit is run for long hours when the air above the ceiling is at high tempera-

ture/high humidity (due point above 26 °C), due condensation may be produced

in the indoor unit. When operating the units in this condition, add insulation mate-

rial (10-20 mm) to the entire surface of the indoor unit to avoid due condensation.

3.1. Install the indoor unit on a ceiling strong

enough to sustain its weight

Warning:

The unit must be securely installed on a structure that can sustain its weight. If

the unit is mounted on an unstable structure, it may fall down causing injuries.

3.2. Securing installation and service space

•

Select the optimum direction of supply airflow according to the configuration of

the room and the installation position.

•

As the piping and wiring are connected at the bottom and side surfaces, and the

maintenance is made at the same surfaces, allow a proper space properly. For

the efficient suspension work and safety, provide a space as much as possible.

[Fig. 3.2.1] (P.2)

3.3. Combining indoor units with outdoor

units

For combining indoor units with outdoor units, refer to the outdoor unit installation

manual.

Part No.

Accessories

Qty

Part No.

Accessories

Qty

1

Insulation pipe

1

5

Installation manual

1

2

Tie band

3

6

Operation manual

1

3

Drain hose

1

4

Washer

8

A

Access door

B

Electrical parts box

C

Air inlet

D

Air outlet

E

Ceiling surface

F

Service space (viewed from the side)

G

Service space (viewed from the direction of arrow)

1

600 mm or more

2

100 mm or more

3

20 mm or more

4

300 mm or more

02_WT06410_GB.fm Page 7 Friday, November 25, 2011 3:59 PM