8

GB

4. Fixing hanging bolts

4.1. Fixing hanging bolts

[Fig. 4.1.1] (P.2)

(Give site of suspension strong structure.)

Hanging structure

•

Ceiling: The ceiling structure varies from building to one another. For detailed

information, consult your construction company.

•

If necessary, reinforce the hanging bolts with anti-quake supporting members as

countermeasures against earthquakes.

* Use M10 for hanging bolts and anti-quake supporting members (field supply).

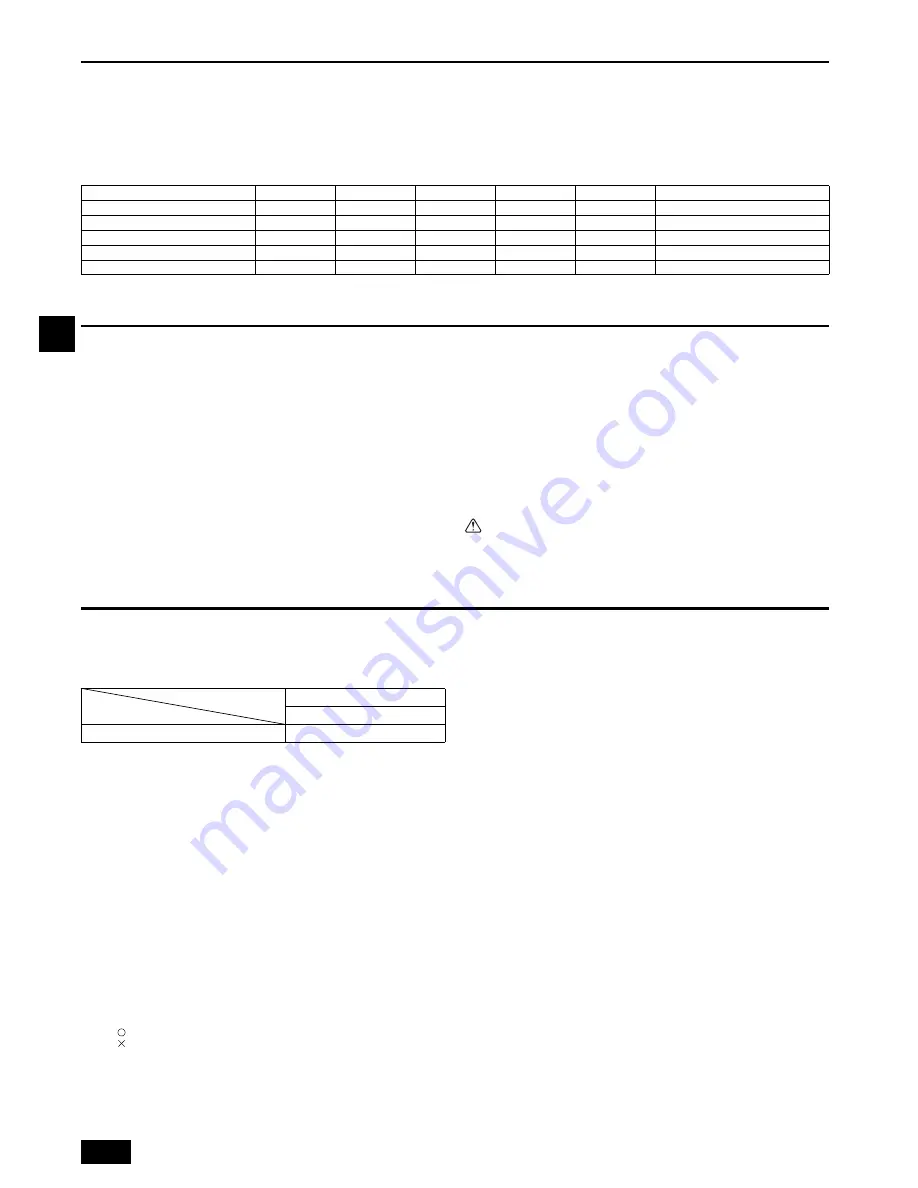

Center of gravity and Product Weight

5. Installing the unit

5.1. Hanging the unit body

`

Bring the indoor unit to an installation site as it is packed.

`

To hang the indoor unit, use a lifting machine to lift and pass through the

hanging bolts.

[Fig. 5.1.1] (P.2)

[Fig. 5.1.2] (P.2)

5.2. Confirming the unit’s position and fixing

hanging bolts

`

Use the gage supplied with the panel to confirm that the unit body and

hanging bolts are positioned in place. If they are not positioned in place, it

may result in dew drops due to wind leak. Be sure to check the positional

relationship.

`

Use a level to check that the surface indicated by

A

is at level. Ensure that

the hanging bolt nuts are tightened to fix the hanging bolts.

`

To ensure that drain is discharged, be sure to hang the unit at level using a

level.

[Fig. 5.2.1] (P.2)

Caution:

Install the unit in horizontal position. If the side with drain port is installed

higher, water leakage may be caused.

6. Connecting drain pipe

To avoid dew drops, provide sufficient antisweating and insulating work to the drain

pipes.

6.1. Drain pipe specifications

6.2. Drain pipe

[Fig. 6.2.1] (P.2)

6.3. Drain piping work

•

Ensure that the drain piping is downward (pitch of more than 1/100) to the out-

door (discharge) side. Do not provide any trap or irregularity on the way.

•

Ensure that any cross-wise drain piping is less than 20 m (excluding the differ-

ence of elevation). If the drain piping is long, provide metal braces to prevent it

from waving. Never provide any air vent pipe. Otherwise drain may be ejected.

•

Use a hard vinyl chloride pipe VP-25 (with an external diameter of 32 mm) for

drain piping.

•

Ensure that collected pipes are 10 cm lower than the unit body’s drain port.

•

Do not provide any odor trap at the drain discharge port.

•

Put the end of the drain piping in a position where no odor is generated.

•

Do not put the end of the drain piping in any drain where ionic gases are gener-

ated.

[Fig. 6.3.1] (P.3)

Grouped piping

1. Insert the drain hose (accessory) into the drain port (insertion margin: 32mm).

(The drain hose must not be bent more than 45° to prevent the hose from break-

ing or clogging.)

(Attach the hose with glue, and fix it with the band (small, accessory).)

2. Attach the drain pipe (O.D. ø32 PVC TUBE PV-25, field supply).

(Attach the pipe with glue, and fix it with the band (small, accessory).)

3. Perform insulation work on the drain pipe (O.D. ø32 PVC TUBE PV-25) and on

the socket (including elbow).

4. Check the drainage. (Refer to [Fig. 6.4.1])

5. Attach the insulating material, and fix it with the band (large, accessory) to insu-

late the drain port.

[Fig. 6.3.2] (P.3)

A

Center of gravity

Model name

W

L

X

Y

Z

Product Weight (kg)

PEFY-WP20VMA-E

643

754

330

300

130

21

PEFY-WP25VMA-E

643

954

340

375

130

26

PEFY-WP32VMA-E

643

954

340

375

130

26

PEFY-WP40VMA-E

643

1154

325

525

130

31

PEFY-WP50VMA-E

643

1154

325

525

130

31

A

Unit body

B

Lifting machine

C

Nuts (field supply)

D

Washers (field supply)

E

M10 hanging bolt (field supply)

A

Indoor unit’s bottom surface

PEFY-WP·VMA-E

20·25·32·40·50

Drain pipe

O.D. ø 32

A

Drain pipe (O.D. ø32)

Correct piping

Wrong piping

A

Insulation (9 mm or more)

B

Downward slope (1/100 or more)

C

Support metal

K

Air bleeder

L

Raised

M

Odor trap

Model

Item

D

O. D. ø32 PVC TUBE

E

Make it as large as possible. About 10 cm.

F

Indoor unit

G

Make the piping size large for grouped piping.

H

Downward slope (1/100 or more)

I

O. D. ø38 PVC TUBE for grouped piping. (9 mm or more insulation)

J

Up to 550 mm

N

Drain hose (accessory)

O

Horizontal or slightly upgradient

A

Indoor unit

B

Tie band (accessory)

C

Visible part

D

Insertion margin

E

Drain hose (accessory)

F

Drain pipe (O.D. ø32 PVC TUBE, field supply)

G

Insulating material (field supply)

H

Tie band (accessory)

02_WT06410_GB.fm Page 8 Friday, November 25, 2011 3:59 PM