GB

5

4. Refrigerant pipe

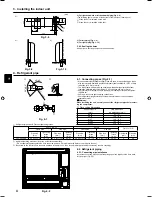

1) For right downward piping (Fig. 4-3)

2) For piping other than right downward (Fig. 4-4)

A

Bands

B

Pipe covers

C

Remove the cover.

• Be sure to insulate the connecting pipes and place them near the rear of the in-

door unit so that they do not contact the front panel.

• Be careful not to crush the connecting pipes when bending them.

Fig. 4-3

Fig. 4-4

2)

1)

3)

Fig. 4-5

Fig. 4-6

Installing flush against a wall with

molding

For left or right piping

3) For left or left-rear piping (Fig. 4-5)

Bundle the connecting pipes and drain hose together, and then wrap them in felt

tape.

A

Make sure that the drain hose is not routed upward.

B

Felt tape

* Wrap the felt tape tightly around the pipes and hose starting near where the

pipes and hose are routed from the indoor unit. (The overlap width of the felt

tape should not be more than 1/2 of the tape width.)

C

Start wrapping the piping tape around the pipes and hose 10 mm inside the

indoor unit.

D

Fasten the end of the felt tape with a bandage stopper.

Cut and use the lower side panels on the left and right sides of the indoor unit as

shown.

Smooth the cut edges of the side panels so that they will not damage the insulation

coating. (Fig. 4-6)

E

Cut the lower side panels to match the height of the modelling.

5. Drainage piping work

5.1. Drainage piping work

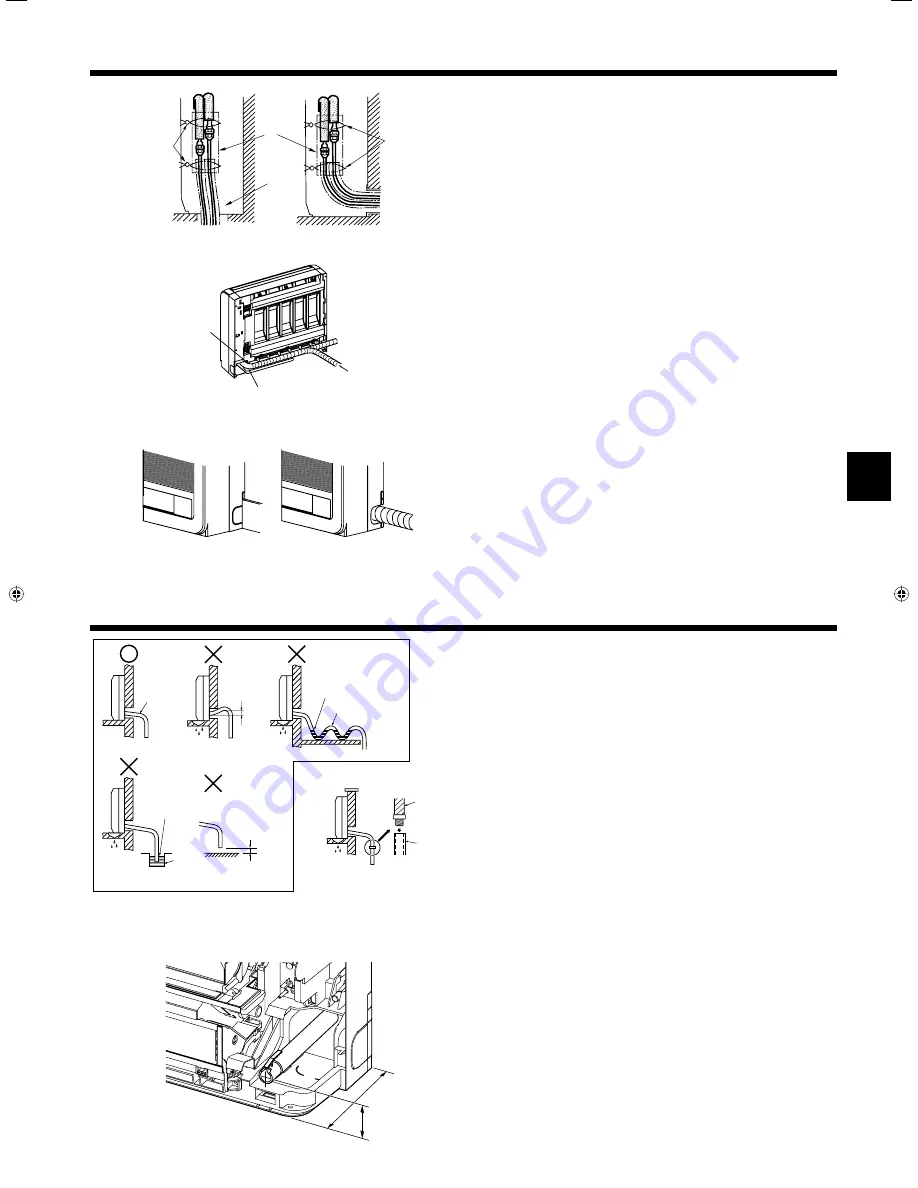

• Be sure to route the drain piping slightly downward (1/100 or more) so that the

drain water flows easily.

• Do not route the drain piping as shown in the examples mark with an “X” in the

figure. (Fig. 5-1)

• If the drain hose is too short, refer to Fig. 5-2 to extend the length of the hose.

• If the indoor unit is installed in a high location such as a high-rise apartment,

strong winds may cause the drain water to flow back through the drain hose and

leak from the unit. If necessary, contact your nearest Mitsubishi Electric repre-

sentative for the optional parts to prevent this problem.

• If the drain hose is routed indoors, be sure to wrap it in commercially-available

insulation.

• Do not connect the drain piping directly to a septic tank, sewage tank, etc., where

ammonia gases or hydrogen sulfide are produced.

• If there is slack in the drain hose or the end of the drain hose is raised up, the

drain water may not flow smoothly and some drain water may collect in the hose.

This can lead to a strange sound (burbling) being produced during strong winds

or when a ventilation fan, etc., is used in a residence that is well-sealed. If neces-

sary, contact your nearest Mitsubishi Electric representative for the optional parts

to prevent this problem.

A

Sloping downward

B

No upward slope

C

Accumulated drain water

D

Air

E

End of drain hose is immersed in water.

F

Drainage channel

G

50 mm or less from ground

H

Drain hose

I

Fixable PVC hose (inner diameter: 15 mm) or rigid PVC pipe (VP-15)

• When routing the drain piping, make sure that the drain hose is routed as shown.

(Fig. 5-3)

Fig. 5-1

Fig. 5-2

50

200

Fig. 5-3