GB

8

1 2 3 4 5 6 7 8 9 10

ON

OFF

SW1

SW5

220V

240V

CN82

CN43

SW14

SWC

. /

.

(BRANCH No.)

0 12

3

4

5

67

89

AB

C

D

EF

SW11

SW12

0 1

2

3

4

5

6

7

8

9

0 1

2

3

4

5

6

7

8

9

(10ths DIGIT)

(1s DIGIT)

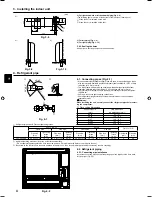

Fig. 7-4

7.5. Setting addresses (Fig. 7-4)

(Be sure to operate with the main power turned OFF.)

• There are 2 types of rotary switch setting available: setting addresses 1 to 9 and

over 10, and setting branch numbers.

1

How to set addresses

Example: If Address is “3”, remain SW12 (for over 10) at “0”, and match

SW11 (for 1 to 9) with “3”.

2

How to set branch numbers SW14 (Series R2 only)

Match the indoor unit’s refrigerant pipe with the BC controller’s end connection

number.

Remain other than series R2 at “0”.

• The rotary switches are all set to “0” when shipped from the factory. These

switches can be used to set unit addresses and branch numbers at will.

• The determination of indoor unit addresses varies with the system at site. Set

them referring to the Data Book.

Note:

Please set the switch SW5 according to the power supply voltage.

• Set SW5 to 240 V side when the power supply is 230 and 240 volts.

• When the power supply is 220 volts, set SW5 to 220 V side.

A

Address board

7.6. Sensing room temperature with the built-in sensor

in a remote controller (Fig.7-4)

If you want to sense room temperature with the built-in sensor in a remote

controller, set SW1-1 on the control board to “ON”. The setting of SW1-7 and

SW1-8 as necessary also makes it possible to adjust the air flow at a time when

the heating thermometer is OFF.

8.1. Before test run

►

After completing installation and the wiring and piping of the indoor and

outdoor units, check for refrigerant leakage, looseness in the power

supply or control wiring, wrong polarity, and no disconnection of one

phase in the supply.

►

Use a 500-volt megohmmeter to check that the resistance between the

power supply terminals and ground is at least 1.0 M

"

.

►

Do not carry out this test on the control wiring (low voltage circuit)

terminals.

Warning:

Do not use the air conditioner if the insulation resistance is less than 1.0 M

"

.

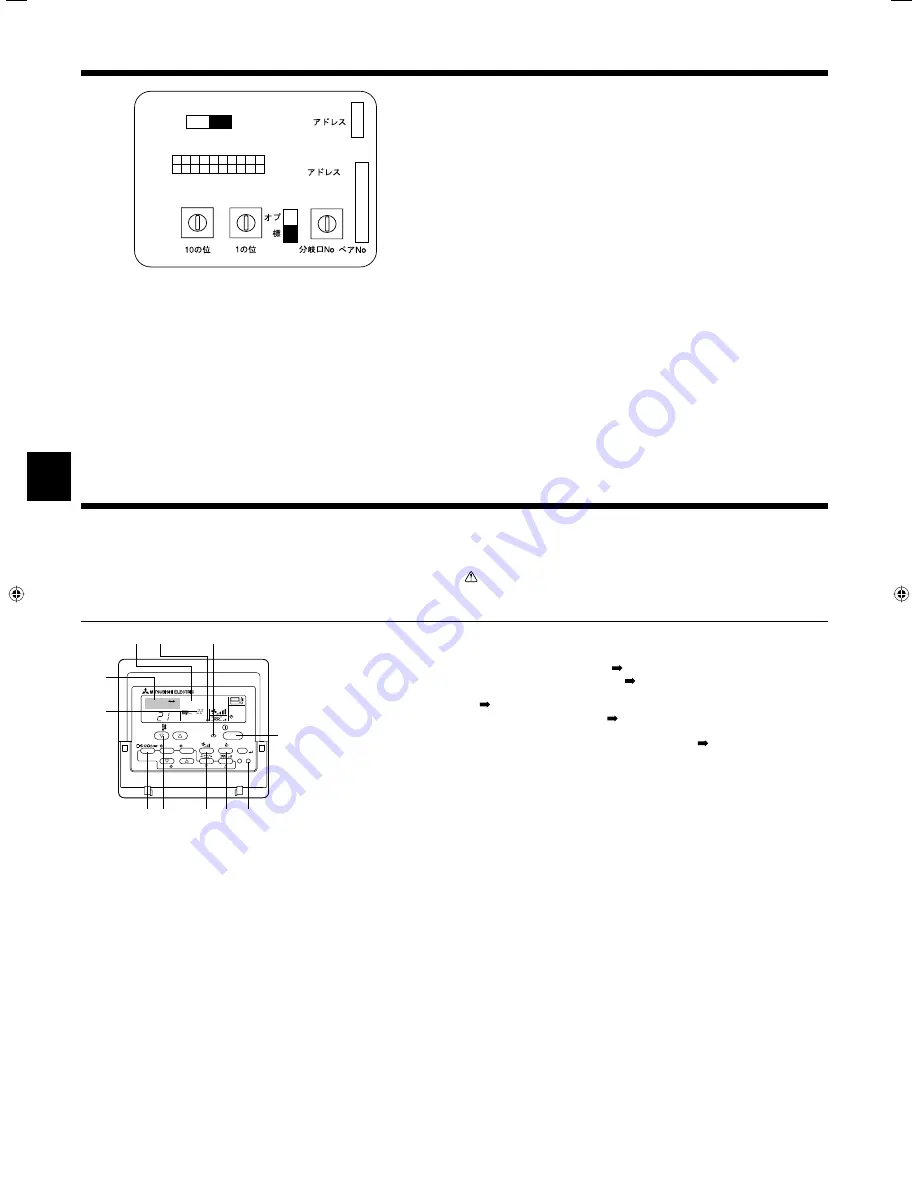

8.2. Test run (Using wired remote controller) (Fig 8-1)

1

Turn on the power at least 12 hours before the test run.

2

Press the [TEST] button twice. “TEST RUN” liquid crystal display

3

Press the [Mode selection] button. Make sure that wind is blown out.

4

Press the [Mode selection] button and switch to the cooling (or heating) mode.

Make sure that cold (or warm) wind is blown out.

5

Press the [Fan speed] button. Make sure that the wind speed is switched.

6

Check operation of the outdoor unit fan.

7

Release test run by pressing the [ON/OFF] button. Stop

8

Register a telephone number.

The telephone number of the repair shop, sales office, etc., to contact if an error

occurs can be registered in the remote controller. The telephone number will be

displayed when an error occurs. For registration procedures, refer to the operation

manual for the indoor unit.

Note:

• If an error code is displayed on the remote controller or if the air conditioner

does not operate properly, refer to the outdoor unit installation manual or

other technical materials.

• The OFF timer is set for the test run to automatically stop after 2 hours.

• During the test run, the time remaining is shown in the time display.

• During the test run, the temperature of the indoor unit refrigerant pipes is

shown in the room temperature display of the remote controller.

• When the VANE or LOUVER button is pressed, the message “NOT

AVAILABLE” may appear on the remote controller display depending on the

indoor unit model, but this is not a malfunction.

• For the PFFY-P•VKM series, the airflow direction displayed on the remote

controller is different from the actual airflow direction. Refer to the

following table.

ON/OFF button

Test run display

Indoor liquid pipe

temperature display

ON/OFF lamp

Power display

Error code display

Test run remaining time

display

Set temperature button

Mode selection button

Fan speed button

Air direction button

TEST button

SIMPLE

PAR-21MAA

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

TEST

TEMP.

MENU

BACK

DAY

MONITOR/SET

CLOCK

ON/OFF

TEST RUN

COOL, HEAT

˚C

˚C

Fig. 8-1

8. Test run

7. Electrical work