3

3. Installing the indoor unit

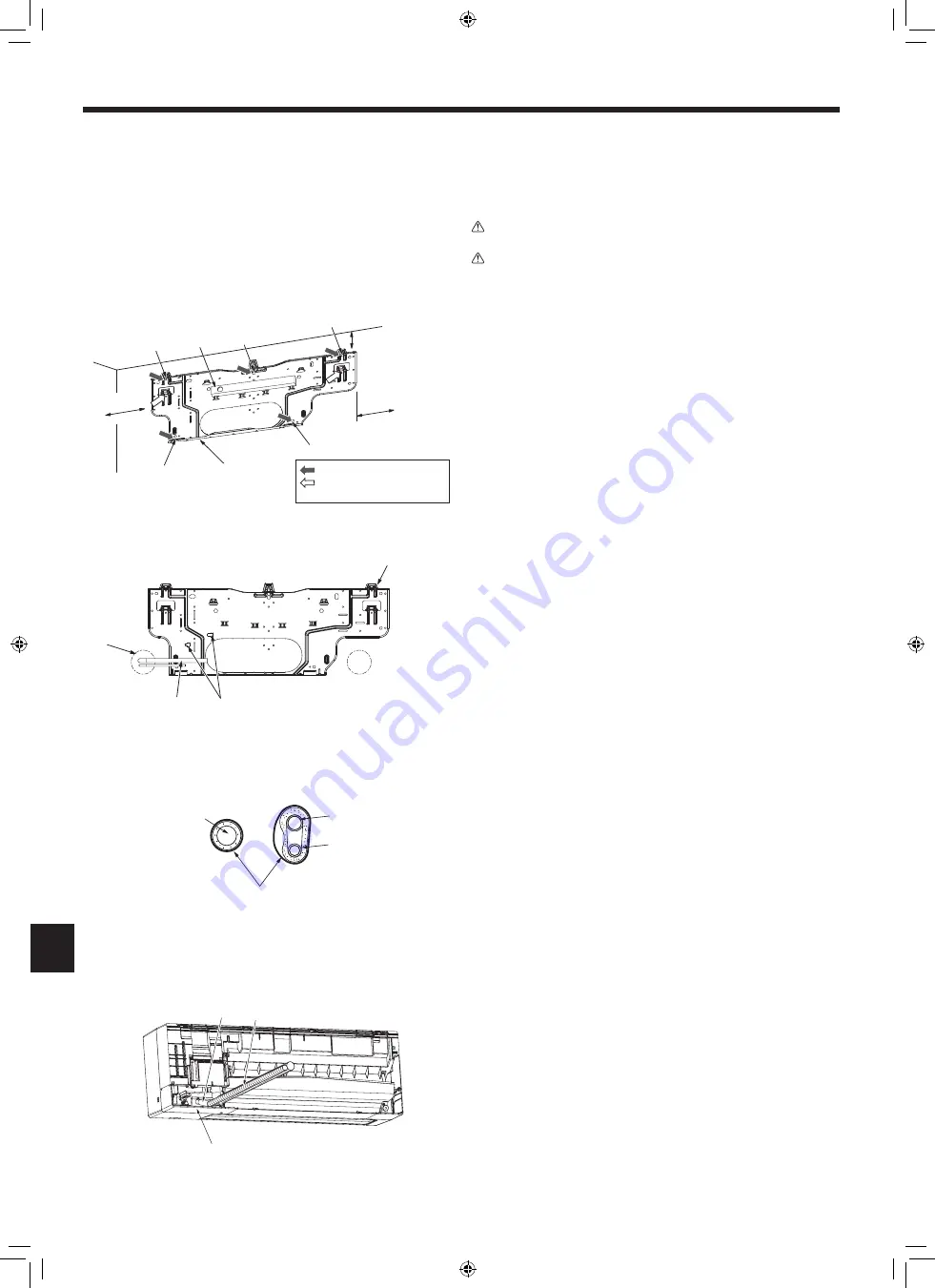

Fig. 3-7

B

A

D

C

3.2.3. Installing the wall mounting fixture

►

Since the indoor unit weighs near 13 kg, 29 lbs, selection of the mounting

location requires thorough consideration. If the wall does not seem to be

strong enough, reinforce it with boards or beams before installation.

►

The mounting fixture must be secured at both ends and at the centre, if

possible. Never fix it at a single spot or in any nonsymetrical way.

(If possible, secure the fixture at all the positions marked with a bold

arrow.)

Warning:

If possible, secure the fixture at all positions indicated with a bold arrow.

Caution:

• The unit body must be mounted horizontally.

• Fasten at the holes as shown by the arrows.

(Fig. 3-5)

■

PKFY-P04/06/08/12NLMU

A

Min. 124 mm, 4-7/8 inch (674 mm, 26-17/32 inch, or greater with optional drain pump

installation)

B

Min. 224 mm, 8-13/16 inch

C

Min. 75 mm, 2-61/64 inch (Use the hook positioned on the lower part of the mount board

when the dimension is less than 100 mm, 3-15/16 inch with left, rear left, or lower left

piping, and optional drain pump installation. Refer to 3.5. for details.)

D

Fixing screws (4 × 25)

2

E

Level

F

Mount board

1

■

PKFY-P15/18NLMU

A

Min. 119 mm, 4-11/16 inch (669 mm, 26-11/32 inch or greater with optional drain pump

installation)

B

Min. 224 mm, 8-13/16 inch

C

Min. 75 mm, 2-61/64 inch (Use the hook positioned on the lower part of the mount board

when the dimension is less than 100 mm, 3-15/16 inch with left, rear left, or lower left

piping, and optional drain pump installation. Refer to 3.5. for details.)

D

Fixing screws (4 × 25)

2

E

Level

F

Mount board

1

3.3. When embedding pipes into the wall (Fig. 3-6)

• The pipes are on the bottom left.

• When the cooling pipe, drain pipes internal/external connection lines etc are to

be embedded into the wall in advance, the extruding pipes etc, may have to be

bent and have their length modified to suit the unit.

• Use marking on the mount board as a reference when adjusting the length of the

embedded cooling pipe.

• During construction, give the length of the extruding pipes etc some leeway.

A

Mount board

1

B

Reference marking for flare connection

C

Through hole

D

On-site piping

3.4. Preparing the indoor unit

* Check beforehand because the preparatory work will differ depending on the

exiting direction of the piping.

* When bending the piping, bend gradually while maintaining the base of the

piping exiting portion. (Abrupt bending will cause misshaping of the piping.)

* Cut off outlet of the pipe depending on the exiting direction of the piping.

Extraction and processing of the piping (Fig. 3-7)

1. Connection of indoor/outdoor wiring → See page 9.

2. Wrap the felt tape

3

in the range of the refrigerant piping and drain hose which

will be housed within the piping space of the indoor unit.

• Wrap the felt tape

3

securely from the base for each of the refrigerant piping

and the drain hose.

• Overlap the felt tape

3

at one-half of the tape width.

• Fasten the end portion of the wrapping with vinyl tape.

A

Liquid pipe

B

Gas pipe

C

Drain hose

D

Felt tape

3

3. Be careful that the drain hose is not raised, and that contact is not made with the

indoor unit box body.

Do not pull the drain hose forcefully because it might come out.

Lower piping (Fig. 3-8)

1) Be careful that the drain hose is not raised, and that contact is not made with

the indoor unit box body.

Arrange the drain hose at the underside of the piping and wrap it with felt

tape

3

.

2) Securely wrap the felt tape

3

starting from the base. (Overlap the felt tape at

one-half of the tape width.)

A

Cut off for lower piping.

A

B

C

D

D

D

F

E

D

D

Fig. 3-6

B

A

C

D

Fig. 3-8

A

1)

2)

Fig. 3-5

: Points to be fastened (5 points)

: Points to be fastened only when

using the lower hook (2 points)

en

RH79A034H02_en.indd 3

2019/12/16 9:54:17

004