2

ON/OFF

TEMP

FAN

VANE

TEST RUN

AUTO STOP

AUTO START

h

min

LOUVER

MODE

CHECK

RESET

SET

CLOCK

MODEL SELECT

NOT AVAILABLE

CHECK TEST RUN

°C

AMPM

AMPM

°F

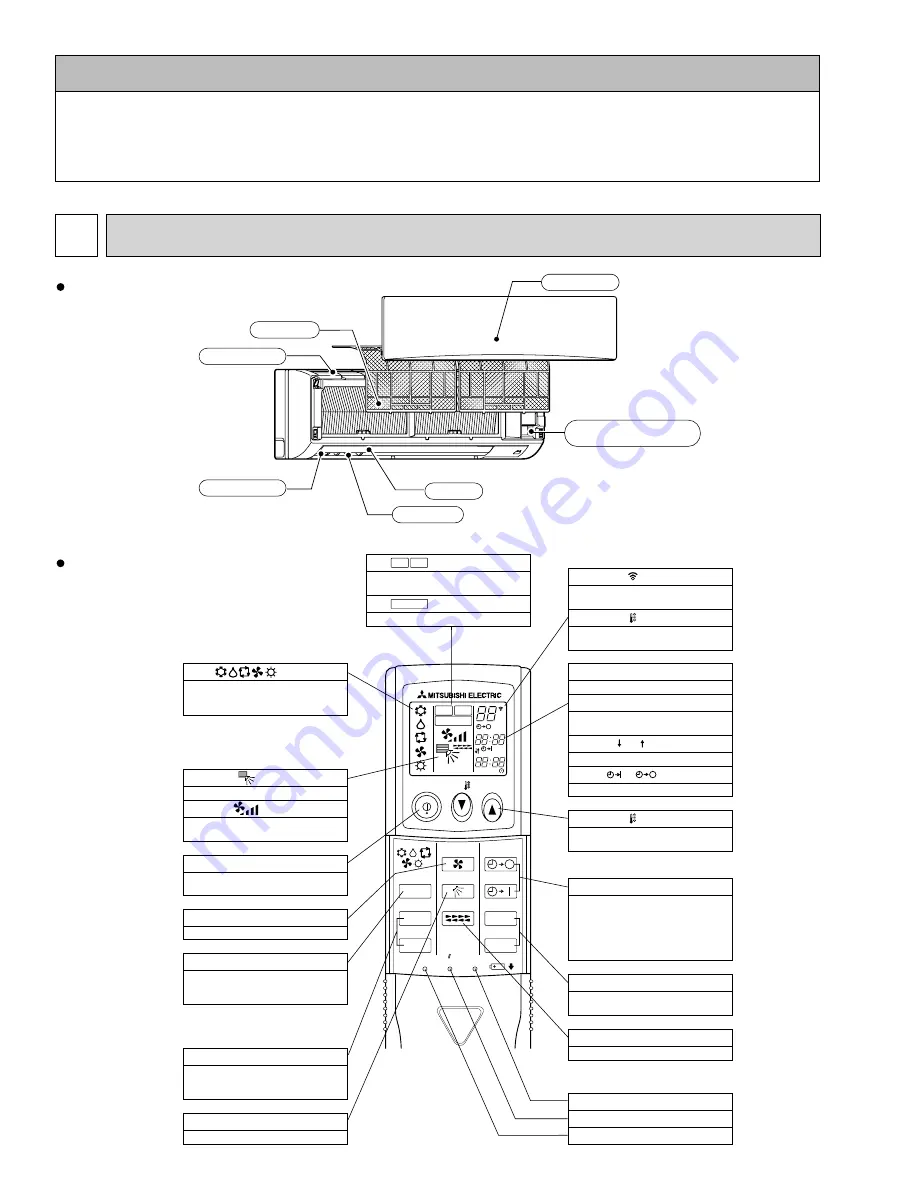

VANE CONTROL button

Used to change the air flow

CLOCK button

RESET button

SET button

ON/OFF button

The unit is turned ON and OFF alternately

each time the button is pressed.

LOUVER button

Changes left/right airflow direction.

(Not available for this model.)

MODE SELECT button

Used to switch the operation mode between

cooling, drying, fan, heating and auto mode.

CHECK-TEST RUN button

Only press this button to perform an

inspection check or test operation.

Do not use it for normal operation.

FAN SPEED SELECT button

Used to change the fan speed.

TIMER display

Displays when in timer operation or when

setting timer.

button

SET TEMPERATURE button sets any desired

room temperature.

CLOCK display

Displays the current time.

“ ” “ ” display

Displays the order of timer operation.

“ ” “ ” display

Displays whether timer is on or off.

+

In case the outdoor unit is cool only type,

the heating and auto mode are not

available.

Buttons used to set the “hour and minute” of

the current time and timer settings.

h and min buttons

display

display

FAN SPEED display indicates which fan

speed has been selected.

display

The vertical direction of air flow is indicated.

display

Blinks when model is selected.

display

display

CHECK and TEST RUN display indicate that

the unit is being checked or test-run.

display

OPERATION MODE display

Operation mode display indicates which

operation mode is in effect.

TIMER CONTROL buttons

AUTO STOP (OFF timer): when this switch is

set, the air conditioner will be automatically

stopped at the preset time.

AUTO START (ON timer): when this switch is

set, the air conditioner will be automatically

started at the preset time.

MODEL SELECT

CHECK TEST RUN

SET TEMP. display indicates the set desired

temperature.

Lights up while the signal is transmitted to

the indoor unit when the button is pressed.

1

PART NAMES AND FUNCTIONS

Indoor unit

Wireless

remote controller

Emergency operation

switch

Front grille

Air inlet

Filter

Air outlet

Louver

Vane

Use the speci

fi

ed refrigerant only.

Never use any refrigerant other than that speci

fi

ed.

Doing so may cause a burst, an explosion, or

fi

re when the unit is being used, serviced, or disposed of.

Correct refrigerant is speci

fi

ed in the manuals and on the spec labels provided with our products.

We will not be held responsible for mechanical failure, system malfunction, unit breakdown or accidents caused by failure to

follow the instructions.