10

11

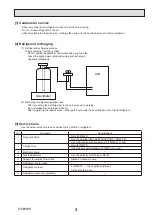

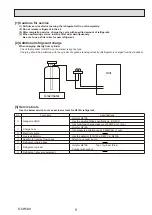

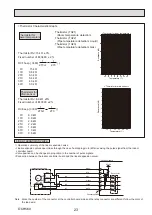

Setting and display items

Setting details

Vane · Louver · Vent.

(Lossnay)

Use to set the vane angle.

• Select a desired vane setting from five different settings.

Use to turn ON / OFF the louver.

• Select a desired setting from "ON" and "OFF."

Use to set the amount of ventilation.

• Select a desired setting from "Off," "Low," and "High."

High power

Use to reach the comfortable room temperature quickly.

• Units can be operated in the High-power mode for up to 30 minutes.

Timer

On/Off timer* Use to set the operation On/Off times.

• Time can be set in 5-minute increments.

Auto-Off

timer

Use to set the Auto-Off time.

• Time can be set to a value from 30 to 240 in 10-minute increments.

Weekly timer*

Use to set the weekly operation On / Off times.

• Up to eight operation patterns can be set for each day.

(Not valid when the On/Off timer is enabled.)

Restriction

Temp. range Use to restrict the preset temperature range.

• Different temperature ranges can be set for different operation modes.

Operation

lock

Use to lock selected functions.

• The locked functions cannot be operated.

Energy

saving

Auto return

Use to get the units to operate at the preset temperature after performing energy-save

operation for a specified time period.

• Time can be set to a value from 30 and 120 in 10-minute increments.

(This function will not be valid when the preset temperature ranges are restricted.)

Schedule*

Set the start/stop times to operate the units in the energy-save mode for each day of the

week, and set the energy-saving rate.

• Up to four energy-save operation patterns can be set for each day.

• Time can be set in 5-minute increments.

• Energy-saving rate can be set to a value from 0% or 50 to 90% in 10% increments.

Night setback*

Use to make Night setback settings.

• Select "Yes" to enable the setting, and "No" to disable the setting. The temperature range and

the start/stop times can be set.

Filter information

Use to check the filter status.

• The filter sign can be reset.

Error information

Use to check error information when an error occurs.

• Check code, error source, refrigerant address, unit model, manufacturing number, contact

information (dealer's phone number) can be displayed.

(The unit model, manufacturing number, and contact information need to be registered in

advance to be displayed.)

Maintenance Manual

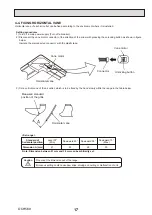

vane angle

Use to set the vane angle for each vane to a fixed position.

Initial setting

Clock

Use to set the current time.

Main display Use to switch between "Full" and "Basic" modes for the Main display.

• The initial setting is "Full."

Contrast

Use to adjust screen contrast.

Language

selection

Use to select the desired language.

Main menu list

* Clock setting is required.

Continue to the next page

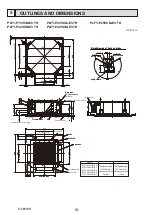

OCH569