19

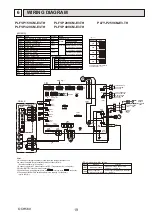

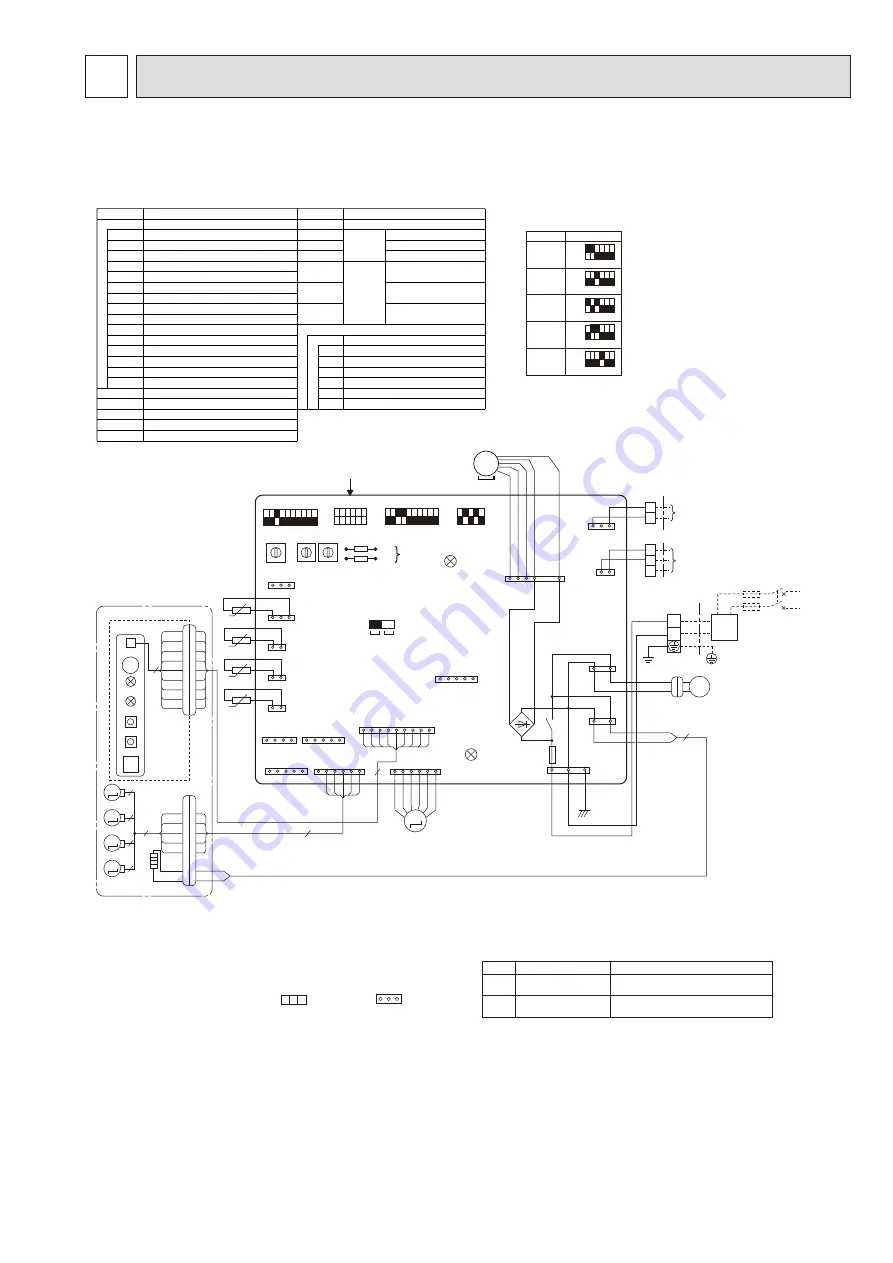

WIRING DIAGRAM

6

SYMBOL

CN32

TERMINAL

BLOCK

POWER SUPPLY

TRANSMISSION

1

4

N

C

CN51

MA-REMOTE CONTROLLER

CN52

ROOM TEMP DETECTION

CN105

(0°C/15k

Ω

,25°C/5.4k

Ω

)

F1

PIPE TEMP DETECTION/LIQUID

SW1

(0°C/15k

Ω

,25°C/5.4k

Ω

)

SW2

PIPE TEMP DETECTION/GAS

SW3

(0°C/15k

Ω

,25°C/5.4k

Ω

)

SW4

I.B

SYMBOL

INDOOR CONTROLLER BOARD

MV

NAME

TH23

TH22

TH21

REMOTE INDICATION

CENTRALLY CONTROL

JEMA HA TERMINAL-A

REMOTE SWITCH

MODEL SELECTION

MODE SELECTION

FUSE(T6.3AL 250V)

NAME

OPTION PART

TB2

TB5

TB15

THERMISTOR

VANE MOTOR

MODE SELECTION

CAPACITY CODE

IT TERMINAL

SW11

BZ

SW12

LED1

SW14

LED2

SWE

RU

X1

SW1

SW2

LEV

MF

ADDRESS SETTING 1s DIGIT

DRAIN PUMP/DEW PREVENTION HEATER

DRAIN PUMP(TEST MODE)

BRANCH No.

ADDRESS SETTING 10ths DIGIT

H2

DP

DRAIN PUMP

DS

DEW PREVENTION HEATER

DRAIN SENSOR

W.B

FAN MOTOR

LINEAR EXPANSION VALVE

LED(PREPARATION FOR HEATING

:

ORANGE)

RECEIVING UNIT

EMERGENCY OPERATION(HEAT)

EMERGENCY OPERATION(COOL)

LED(OPERATION INDICATOR

:

GREEN)

PCB FOR WIRELESS REMOTE CONTROLLER

BUZZER

Notes:

1.At servicing for outdoor unit,always follow the wiring diagram of outdoor unit.

2.In case of using MA-Remote controller, please connect to TB15.

(Remote controller wire is non-polar.)

3.In case of using M-NET, please connect to TB5. (Transmission line is non-polar.)

4.Symbol [S]of TB5 is the shield wire connection.

5.Symbols used in wiring diagram above are, : terminal block, : connecter.

6.The setting of the SW2 dip switches differs in the capacity. For the detail,

refer to the fig:*1.

Mark

Meaning

Function

Power supply for

MA-Remote controller

Main power supply (Indoor unit)

Power on → Iamp is lit

LED on indoor board for service

LED1

Main power supply

Power supply for MA-Remote controller

on → Iamp is lit

LED2

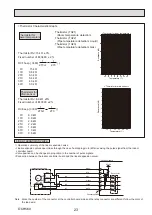

MODELS

P20

SW2

123456

ON

OFF

P15

123456

ON

OFF

P25

123456

ON

OFF

P32

123456

ON

OFF

P40

123456

ON

OFF

LED1

12345

SW4

ON

OFF

12345678910

SW1

SW3

12345678910

123456

SW2

ON

OFF

ON

OFF

See fig *1

TB5

M1

M2

TB15

1

S

2

TO MA-REMOTE

CONTROLLER

DC8.7-13V

TO OUTDOOR UNIT

BC CONTROLLER

M-NET REMOTE

CONTROLLER

DC24-30V

SWE

OFF ON

10

LED2

LED1

1

1

9

2

2

3

3

4

6

6

7

7

8

5

5

5

W.B

GRILLE

M

MV

RED

YLW

YLW

YLW

H2

WHT

VLT

ORN

RED

YLW

ORN

BLU

PINK

GRY

SKY BLU

BLU

BRN

5

M

MV

5

9

5

M

MV

5

M

MV

CNB

SW1

BZ

RU

SW2

L

N

BLU

YLW

YLW

YLW

YLW

TB2

RED

GRN/YLW

PULL

BOX

FUSE

(16A)

BREAKER

(16A)

TO NEXT

INDOOR

UNIT

POWER

SUPPLY

~/N220-240V

50Hz

M

LEV

RED

YLW WHT

ORN

BLU

RED

BLU

BLK

BRN

0 1

2

3

45

6

7

8

9

SW12

0 1

2

3

45

6

7

8

9

SW11

SW14

10ths

DIGIT

1s

DIGIT

BRANCH

No.

0 12

34

56

789

AB

C

D

E F

1

3

M

1~

DP

+

–

ON

OFF

I.B

MF

MS

3~

1

9

CN90

(WHT)

1

6

1

6

CN60

(WHT)

1

5

CN51

(WHT)

1

4

CN41

(WHT)

1

5

CN52

(GRN)

1

5

CN105

(RED)

t°

t°

t°

t°

DS

TH22

TH21

TH23

1

3

CN31

(WHT)

1

3

CN32

(WHT)

1

2

CN20

(RED)

1

2

CN29

(BLK)

1

2

CN21

(WHT)

CN6V

(GRN)

1

7 6 5 4

CNMF

(WHT)

1

5

CND

(BLK)

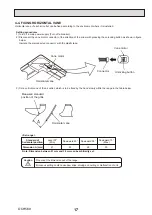

<fig.*1>

The black square (■) indicates

a switch position. <*1>

X1

1

3

1

3

1

2

CN2M

(BLU)

1

3

CN3A

(BLU)

BLU YLW WHT BLK

RED

2

5

9

CNP

(BLU)

F1

CNC

(RED)

J42

J41 Pair No.

LED2

BLU

BLU

ORN

ORN

* Case of wireless grille type

[LEGEND]

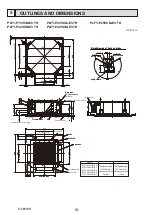

PLFY-P15VCM-E3.TH

PLFY-P20VCM-E3.TH

PLFY-P25VCM-E3.TH

PLFY-P32VCM-E3.TH PLFY-P40VCM-E3.TH

OCH569