25

GB

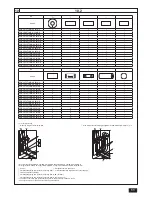

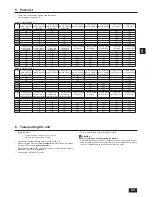

9. Refrigerant piping installation

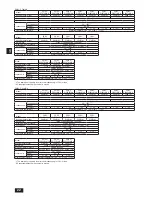

Copper pipe size and radial thickness for R410A CITY MULTI.

6L]HPP 6L]HLQFK

Radial thickness

PP

Radial thickness

PLO

Pipe type

ø6.35

ø1/4"

0.8

32

Type-O

ø9.52

ø3/8"

0.8

32

Type-O

ø12.7

ø1/2"

0.8

32

Type-O

ø15.88

ø5/8"

1.0

40

Type-O

*ø19.05

ø3/4"

1.2

48

Type-O

*ø19.05

ø3/4"

1.0

40

Type-1/2H or H

ø22.2

ø7/8"

1.0

40

Type-1/2H or H

ø25.4

ø1"

1.0

40

Type-1/2H or H

ø28.58

ø1-1/8"

1.0

40

Type-1/2H or H

ø31.75

ø1-1/4"

1.1

44

Type-1/2H or H

ø34.93

ø1-3/8"

1.2

48

Type-1/2H or H

ø41.28

ø1-5/8"

1.4

56

Type-1/2H or H

%RWKSLSHW\SHVFDQEHXVHGIRUSLSHVL]H¡LQFKIRU5$DLU

conditioner.

6

8VHD¿WWLQJLIDVSHFL¿HGUHIULJHUDQWSLSHKDVDGLIIHUHQWGLDPHWHUIURPWKDW

of a branching pipe.

7

Follow the restrictions on the refrigerant piping (such as rated length, height

GLIIHUHQFHDQGSLSLQJGLDPHWHUWRSUHYHQWHTXLSPHQWIDLOXUHRUDGHFOLQHLQ

heating/cooling performance.

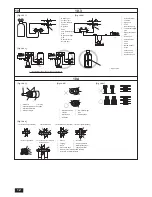

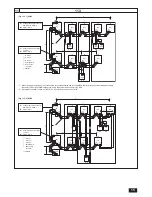

,QGRRUWZLQQLQJSLSHVHW<3ā76/08$<6/08$21/<

Line branch

Down-stream unit

model

Less than 72 in

total

Down-stream unit

model

More than 73 and

less than 144 in

total

Down-stream unit

model

More than 145

and less than 240

in total

Down-stream unit

model

More than 241 in

total

CMY-Y102SS-G2

CMY-Y102LS-G2

CMY-Y202S-G2

CMY-Y302S-G2

Indoor twinning pipe set model

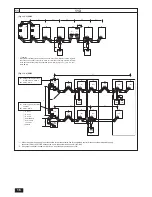

34+<3ā76/08$<6/08$21/<

Header branch

4 branching

8 branching

10 branching

CMY-Y104C-G

CMY-Y108C-G

CMY-Y1010C-G

Heat source twinning kit model

34+<3ā76/08$<6/08$21/<

Total heat source model

P144 ~ P240

Total heat source model

P288 ~ P360

CMY-Y100CBK3

CMY-Y200CBK2

8

Indoor units cannot be further branched down stream after the branch

KHDGHU6HHGLDJUDP<3ā76/08$<6/08$21/<

To the heat source unit

CAP

To the heat source

unit

The pipe is connected via a terminal-branch type connection in which refrigerant

piping from the heat source unit is branched at the terminal and is connected to

each of the indoor units.

7KHPHWKRGRISLSHFRQQHFWLRQLVDVIROORZVÀDUHFRQQHFWLRQIRUWKHLQGRRUXQLWV

*DVORZSUHVVXUHIRU345<3ā76/08$<6/08$SLSHVDQG/LTXLGKLJK

SUHVVXUHIRU345<3ā76/08$<6/08$SLSHVIRUKHDWVRXUFHEUD]HG

connection. Note that the branched sections are brazed.

Warning:

Do not use refrigerant other than the type indicated in the manuals

provided with the unit and on the nameplate.

'RLQJVRPD\FDXVHWKHXQLWRUSLSHVWREXUVWRUUHVXOWLQH[SORVLRQRU¿UH

during use, during repair, or at the time of disposal of the unit.

- It may also be in violation of applicable laws.

- MITSUBISHI ELECTRIC CORPORATION cannot be held responsible

for malfunctions or accidents resulting from the use of the wrong type of

refrigerant.

Always use extreme care to prevent the refrigerant gas from leaking while

XVLQJ¿UHRUÀDPH,IWKHUHIULJHUDQWJDVFRPHVLQWRFRQWDFWZLWKDÀDPH

from any source, such as a gas stove, it breaks down and generates

a poisonous gas which can cause gas poisoning. Never weld in an

unventilated room. Always conduct an inspection for gas leakage after

installation of the refrigerant piping has been completed.

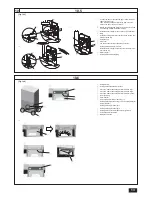

9.1. Caution

This unit uses refrigerant R410A. Follow the local regulations on materials and

pipe thickness when selecting pipes.

5HIHUWRWKHWDEOHEHORZ

1

Use the following materials for refrigeration piping.

Material: Use copper alloy seamless pipes made of phosphorus

deoxidized copper. Ensure the inside and outside surfaces of

the pipes are clean and free from hazardous sulfur, oxide, dusts,

VKDYLQJSDUWLFOHVRLOVDQGPRLVWXUHFRQWDPLQDWLRQ

Size: Refer to item 9.2. for detailed information on refrigerant piping

system.

2

Field-supplied piping often contains dust and other materials. Always blow it

clean with a dry inert gas.

3

Use care to prevent dust, water or other contaminants from entering the

piping during installation.

4

Reduce the number of bending portions as much as possible, and make

bending radii as big as possible.

5

For branching and connecting pipes for indoor and heat source units, use

WKHIROORZLQJWZLQQLQJDQGFRQQHFWLQJSLSHVHWVVROGVHSDUDWHO\

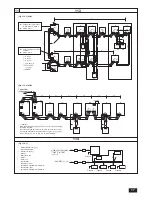

Indoor twinning pipe kit model

345<3ā76/08$

<6/08$21/<

,QGRRUMXQFWLRQSLSHNLWPRGHO

345<3ā76/08$

<6/08$21/<

Line branch

Total indoor model

P72~P96

Down-stream unit model

Less than 30 in total

CMY-Y102SS-G2

CMY-R160C-J

Heat source twinning kit model

345<3ā76/08$<6/08$21/<

Total heat source model

P144 ~ P240

Total heat source model

P288 ~ P336

CMY-Q100CBK2

CMY-Q200CBK

3

Consult with a specialist about water quality control methods and

calculations before using anti-corrosive solutions.

4

When replacing a previously installed air conditioning device (even when

RQO\WKHKHDWH[FKDQJHULVEHLQJUHSODFHG¿UVWFRQGXFWDZDWHUTXDOLW\

analysis and check for possible corrosion.

Corrosion can occur in cold-water systems even if there has been no

prior signs of corrosion.

,IWKHZDWHUTXDOLW\OHYHOKDVGURSSHGDGMXVWZDWHUTXDOLW\EHIRUH

replacing the unit.

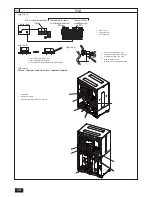

8.4. Pump

interlock

The heat source unit may become damaged if it is operated with no water

circulating through the pipes.

Interlock unit operation and the water-circuit pump. Use the terminal

EORFNVIRULQWHUORFNLQJ7%WKDWFDQEHIRXQGRQWKHXQLW

In the case of a pump interlock circuit signal connection to the TB8-3, 4, remove

the short-circuit wire. Also, use pressure valve 63PW with a minimum current of

5mA or less to prevent miss detection due to poor connection.

Pump interlock cords of parts of appliances for heat source use shall not be

OLJKWHUWKDQSRO\FKORURSUHQHVKHDWKHGÀH[LEOHFRUGGHVLJQ,(&

[Fig. 8.4.1] (P.3)

A

3XPSLQWHUORFNFLUFXLWFRQQHFWLRQ¿HOGVXSSOLHG

[Fig. 8.4.2] (P.3)

This circuit is for interlocking of the heat source unit operation and the water-

circuit pump.

A

Heat source unit

B

&RQWUROSDQHO¿HOGVXSSOLHG

C

To next heat source unit

X :

Relay

FS :

Flow

switch

52P

: Magnetic contactor for water circuit pump

MP

: Water circuit pump

MCB :

Circuit

breaker

* Remove the short circuit wire between 3 and 4 when wiring to TB8.

* Use an insulated ring terminal to connect the wiring to TB8.

Summary of Contents for CITY MULTI PQHY-P-TLMU-A

Page 55: ......