28

GB

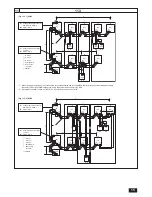

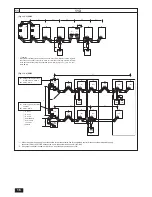

<Example of refrigerant piping connection>

[Fig.10.2.2] (P.10 - 11)

1

&RQQHFWLQJHOERZ,'>@2'>@,QFOXGHGZLWKKHDW

source unit>

2

&RQQHFWLQJSLSH,'>@2'>@,QFOXGHGZLWKKHDWVRXUFH

unit>

3

:DWHUVWRSSHU/LTXLG

4

:DWHUVWRSSHU*DV/RZSUHVVXUH

5

6HDOLQJPDWHULDOIRUZDWHUVWRSSHU/LTXLG

6

6HDOLQJPDWHULDOIRUZDWHUVWRSSHU*DV/RZSUHVVXUH

7

6HDOLQJPDWHULDOIRU¿HOGSLSLQJ/LTXLG+LJKSUHVVXUH

8

6HDOLQJPDWHULDOIRU¿HOGSLSLQJ*DV/RZSUHVVXUH

9

Sealing material for base leg

0

Sealing material for base leg

a

Sealing material for water panel

b

3LSHFRYHU*DV/RZSUHVVXUH

c

Sealing material for drain socket

<A> Front pipe routing

<B>

/RZSUHVVXUHVLGH345<3ā76/08$<6/08$*D<

3ā76/08$<6/08$

<C>

+LJKSUHVVXUHVLGH345<3ā76/08$<6/08$/LTXL<

3ā76/08$<6/08$

A

Shape

B

Without a low-pressure twinning pipe

C

:LWKDORZSUHVVXUHWZLQQLQJSLSH345<3ā76/08$<6/08$21/<

D

Refrigerant service valve pipes

E

)LHOGVXSSOLHGSLSLQJORZSUHVVXUHFRQQHFWLQJSLSH

F

)LHOGVXSSOLHGSLSLQJKLJKSUHVVXUHFRQQHFWLQJSLSH

G

7ZLQQLQJNLWVROGVHSDUDWHO\

H

)LHOGVXSSOLHGSLSLQJORZSUHVVXUHFRQQHFWLQJSLSHWR%&FRQWUROOHU

I

)LHOGVXSSOLHGSLSLQJORZSUHVVXUHFRQQHFWLQJSLSHWRKHDWVRXUFHXQLW

7RDWWDFKWKH7ZLQQLQJSLSHVROGVHSDUDWHO\UHIHUWRWKH

instructions included in the kit.

*2 Connection pipe is not used when the Twinning Kit is attached.

Pipe routing (for PQHY-P·TLMU-A/YLMU-A)

P72

P96, P120

: Use the included connecting pipe

3

to connect.

P72

: Use the included connecting pipe

1

,

2

to connect.

P96, P120

8VHWKHSLSHMRLQW¿HOGVXSSO\DQGWKHLQFOXGHG

connecting pipe

1

to connect.

Pipe routing (for PQRY-P·TLMU-A/YLMU-A)

P72

8VHWKHSLSHMRLQW¿HOGVXSSO\DQGFRQQHFWWRWKH

refrigerant service valve piping.

P96, P120

([SDQGWKHKLJKSUHVVXUHVLGH¿HOGVXSSOLHGSLSLQJ

,'>@DQGFRQQHFWWRWKHUHIULJHUDQW

service valve piping.

P72

: Use the included connecting pipe

1

,

2

to connect.

P96, P120

8VHWKHSLSHMRLQW¿HOGVXSSO\DQGWKHLQFOXGHG

connecting pipe

1

to connect.

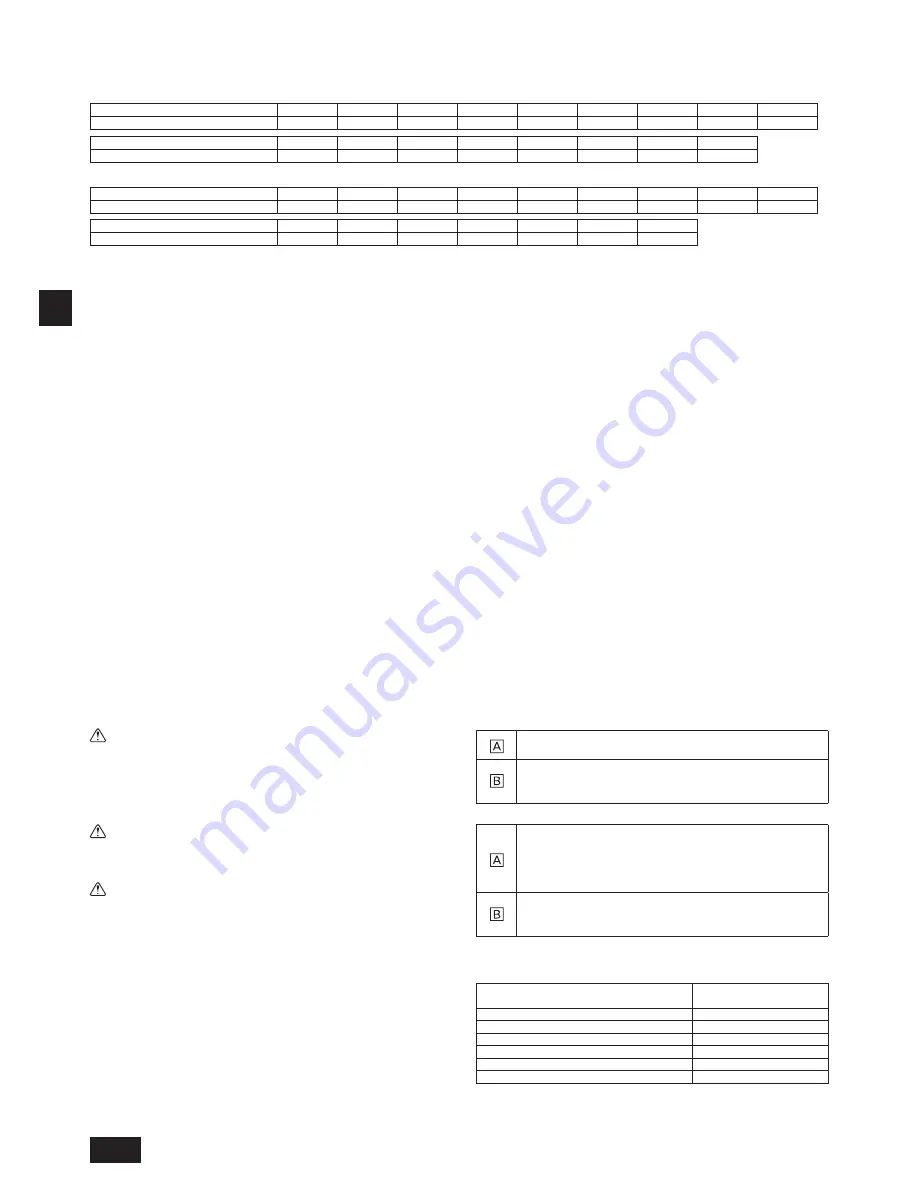

6DWLVI\WKHPLQLPXPLQVHUWLRQGHSWKLQWKHWDEOHEHORZZKHQH[SDQGLQJ¿HOG

supplied piping

Pipe diameter

PP>LQ@

Minimum insertion depth

PP>LQ@

5 [7/32] or more, less than 8 [11/32]

6 [1/4]

8 [11/32] or more, less than 12 [1/2]

7 [9/32]

12 [1/2] or more, less than 16 [21/32]

8 [11/32]

16 [21/32] or more, less than 25 [1]

10 [13/32]

25 [1] or more, less than 35 [1-13/32]

12 [1/2]

35 [1-13/32] or more, less than 45 [1-25/32]

14 [9/16]

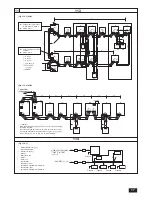

After evacuation and refrigerant charging, ensure that the handle is fully

open. If keep the valve closed, the high- or low-pressure side of the

UHIULJHUDQWFLUFXLWPD\EHVXEMHFWHGWRDEQRUPDOSUHVVXUHDQGPD\GDPDJH

the compressor, four-way valve, etc.

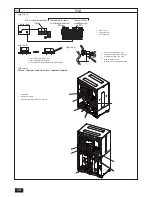

10.2. Precautions concerning piping

connection and valve operation

Conduct piping connection and valve operation accurately and carefully.

Removing the pinched connecting pipe

When shipped, a pinched connecting pipe is attached to the on site high-

pressure/liquid and low-pressure/gas valves to prevent gas leakage.

Take the following steps

1

through

4

to remove the pinched connecting

pipe before connecting refrigerant pipes to the heat source unit.

1

&KHFNWKDWWKHUHIULJHUDQWVHUYLFHYDOYHLVIXOO\FORVHGFORFNZLVH

2

Connect a charging hose to the service port on the low-pressure/

high-pressure liquid/gas refrigerant service valve, and extract the gas

in the piping between the refrigerant service valve and the pinched

FRQQHFWLQJSLSH7LJKWHQLQJWRUTXH1āP>NJāFP@

3

After vacuuming gas from the pinched connecting pipe, sever the

pinched connecting pipe at the location shown in [Fig.10.2.1] and drain

the refrigerant.

4

After completing

2

and

3

, heat the brazed section to remove the

pinched connecting pipe.

[Fig. 10.2.1] (P.10)

<A> Service valve for refrigerant

/LTXLGVLGHEUD]<3ā76/08$<6/08$

+LJKSUHVVXUHVLGHEUD]HGIRU345<3ā76/08$<6/08$

<B> Service valve for refrigerant

*DVVLGHEUD]<3ā76/08$<6/08$

/RZSUHVVXUHVLGHEUD]HGIRU345<3ā76/08$<6/08$

A

Shaft

B

Service port

C

Cap

D

Pinched connecting pipe severing portion

E

Pinched connecting pipe brazing portion

Warning:

The areas between the refrigerant service valves and the pinched

FRQQHFWLQJSLSHVDUH¿OOHGZLWKJDVDQGUHIULJHUDQWRLO([WUDFWWKHJDV

and refrigerant oil in that section before heating the brazed section.

,IWKHEUD]HGVHFWLRQLVKHDWHGZLWKRXW¿UVWH[WUDFWLQJWKHJDVDQG

refrigerant oil, the pipe may burst or the pinched connecting pipe may blow

RIIDQGLJQLWHWKHUHIULJHUDQWRLOFDXVLQJVHULRXVLQMXU\

Caution:

Place a wet towel on the refrigerant service valve before heating the brazed

VHFWLRQWRNHHSWKHYDOYHWHPSHUDWXUHIURPH[FHHGLQJÛ&>Û)@

'LUHFWWKHÀDPHDZD\IURPWKHZLULQJDQGPHWDOVKHHWVLQVLGHWKHXQLW

Caution:

Refrigerant pipe connection

7KLVSURGXFWLQFOXGHVFRQQHFWLQJSLSHVIRUIURQWSLSLQJ5HIHUWR>)LJ@

Check the high-pressure/low-pressure piping dimensions before connecting

the refrigerant pipe.

Refer to item 9.2 Refrigerant piping system for piping dimensions.

Make sure that the refrigerant pipe does not touch other refrigerants pipes,

unit panels, or base plates.

Use non-oxidative brazing when connecting pipes.

Do not burn the wiring and plate when brazing.

J

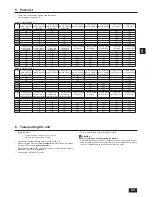

Limitation of the amount of refrigerant to be charged

The above calculation result of the amount of refrigerant to be charged must become below the value in the table below.

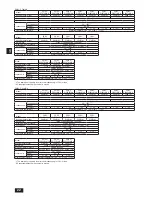

)RU34+<3ā76/08$<6/08$

Heat source unit model

P72

P96

P120

P144

P144S

P168

P168S

P192

P192S

Maximum amount of refrigerant

*1

kg [LBS]

22.0 [49]

28.5 [63]

29.5 [66]

42.0 [93]

42.0 [93]

51.5 [114]

51.5 [114]

53.5 [118]

53.5 [118]

Heat source unit model

P216

P216S

P240

P240S

P288S

P312S

P336S

P360S

Maximum amount of refrigerant

*1

kg [LBS]

56.0 [124]

55.0 [122]

57.0 [126]

56.0 [124]

67.5 [149]

67.5 [149]

67.5 [149]

70.0 [155]

)RU345<3ā76/08$<6/08$

Heat source unit model

P72

P96

P120

P144

P144S

P168

P168S

P192

P192S

Maximum amount of refrigerant

*1

kg [LBS]

28.0 [62]

32.0 [71]

33.0 [73]

44.0 [98]

44.0 [98]

45.0 [100]

45.0 [100]

52.0 [115]

50.0 [111]

Heat source unit model

P216

P216S

P240

P240S

P288S

P312S

P336S

Maximum amount of refrigerant

*1

kg [LBS]

57.0 [126]

62.0 [137]

58.0 [128]

59.0 [131]

74.0 [164]

74.0 [164]

76.0 [168]

*1: Amount of additional refrigerant to be charged on site

Summary of Contents for CITY MULTI PQHY-P-TLMU-A

Page 55: ......