CAUTION

Use the power that are complied with the power specification conditions (input voltage, input

frequency, tolerable instantaneous power failure time) indicated in each specifications manual.

When making detector cables, do not mistake connection. Failure to observe this could result in

malfunction, runaway or fire.

When using NC Card, first power ON the NC Card, and then the base I/O unit. If the base I/O unit is

powered ON first, current flows from the connection cable to the NC Card, resulting in malfunction in

the PC or the cards installed in the PC.

(5) Troubleshooting

CAUTION

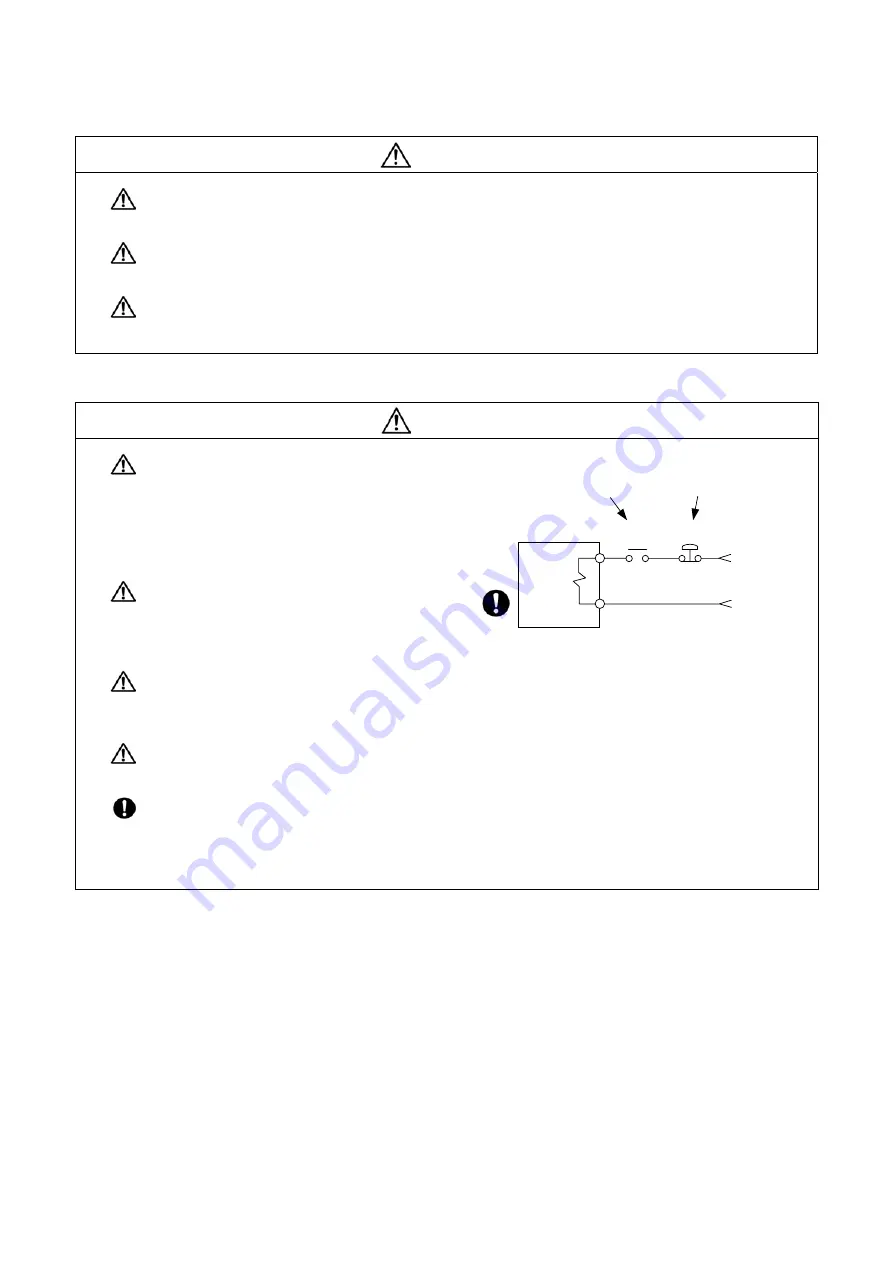

Use a motor with electromagnetic brakes or

establish an external brake mechanism for the

purpose of holding; this serves as

countermeasures for possible hazardous

situation caused by power failure or product

fault.

Use a double circuit structure for the

electromagnetic brake’s operation circuit so

that the brakes will activate even when the

external emergency stop signal is issued.

Motor

Electro-

magnetic

brake

Shut off with motor

brake control output

Shut off with CNC brake

control PLC output

MBR

EMG

24VDC

The machine could suddenly restart when the power is restored after an instantaneous power

failure, so stay away from the machine. (Design the machine so that the operator safety can be

ensured even if the machine restarts.)

To secure the absolute position, do not shut off the servo drive unit’s control power supply when its

battery voltage drops (warning 9F) in the servo drive unit side.

If the battery voltage drop warning alarm occurs in the controller side, make sure to back up the

machining programs, tool data and parameters, etc. with the input/output device before replacing the

battery.

Depending on the level of voltage drop, memory loss could have happened. In that case, reload all

the data backed up before the alarm occurrence.