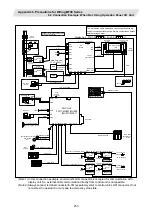

Appendix 6. Precautions for Wiring M700 Series

6.1 Connecting the Optical Fiber Cable

248

6.1.3 Precautions for Laying Optical Fiber Cable

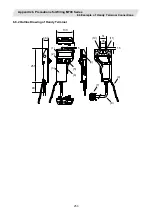

(1) Do not apply a force exceeding the cable's tolerable tension. Binding the cables too tight with tie-wraps

could result in an increased loss or a disconnection. Use a cushioning material such as a sponge or

rubber when bundling the cables and fix so that the cables do not move.

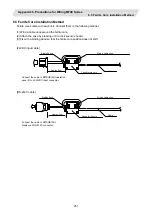

(2) Do not connect the cables with a radius less than the tolerable bending radius. Excessive stress could be

applied near the connector connection section and cause the optical characteristics to drop. The cable

bending radius should be 10 times or more than the outer diameter at the reinforced sheath, and 20

times or more than the outer diameter at the fiber cord section.

(3) Do not apply torsion to the optical fiber cable. Laying a twisted cable could cause the optical

characteristics to drop.

(4) When laying the cables in a conduit, avoid applying stress on the fiber cord and connector connection

section. Use the tensile end such as a pulling eye or cable grip, etc.

(5) Fix the reinforced sheath with a cable clamp so that the mass of the optical fiber cable is not directly

applied on the fiber cord and connector connection section.

(6) Never bundle the cables with vinyl tape. The plasticizing material in the vinyl tape could cause the POF

cable to break.

(7) Loop the excessive cable with twice or more than the minimum bending radius R.

Recommended clamp material: CKN-13SP KITAGAWA INDUSTRIES.

6.2 Precautions for Connecting Peripheral Devices

(1) There is compatibility between the devices connected to the commercially available compact flash

memory and USB interface, so not all operations can be guaranteed. The operation must be confirmed

by the machine tool builder.

The dustproof properties, splashproof properties and noise effect, etc., of the commercially available

devices may not be taken into consideration in all cases.

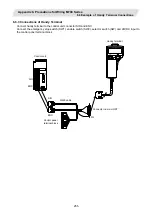

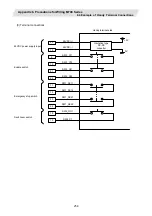

6.3 Precautions for Connecting 24V Power Supply

(1) When 24V power is supplied to the unit (control unit, display unit) under the following conditions,

welding may occur on the contacts due to rush current; so be careful.

When 24VDC's ON/OFF are directly controlled by a magnetic switch such as relay AND

When heat capacity of the contacts for relay, etc. used to control 24VDC's ON/OFF is small.